Welcome to Glen Refrigeration blog. We share insights, basic practices, and other HVACR information here. Now we intend to help our customers to learn more about the usage and installation of horizontal condensing unit.

What Is An Horizontal Condensing Unit?

The horizontal condensing unit is an air cooled indoor condensing unit, installed at the bottom or rooftop of the refrigerated display cabinets. So it is also called self contained condensing unit.

What Does Horizontal Condensing Unit Consist?

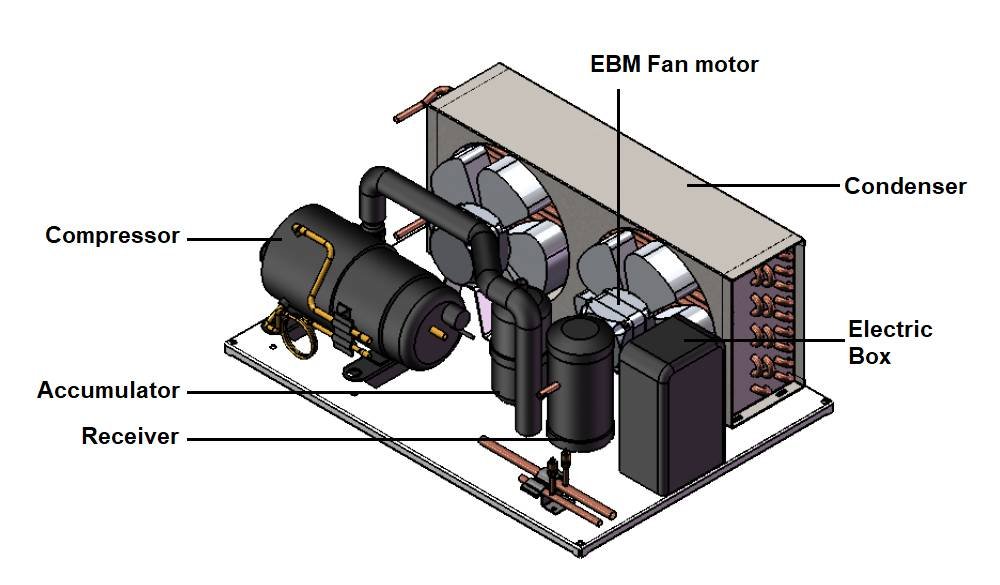

The horizontal condensing unit consists of Sanyo horizontal rotary refrigeration compressor, Condenser, EBM fan motor, receiver, high and low pressure switch, accumulator, one way valve. It is a part of commercial refrigeration system.

Sanyo Rotary Refrigeration Compressor: The air cooled indoor condensing unit features Sanyo horizontal rotary refrigeration compressor. It has the advantages of high reliability and high efficiency.

Condenser: The low height condenser, with the fin space 3.5mm, is special designed for horizontal condensing unit, preventing dirty blockage.

EBM Fan Motor: EBM fan motor ensures the high reliability of horizontal condensing unit.

Receiver: The receiver can store the refrigerant, preventing too much refrigerant in the condenser, increasing the heat transfer area and the heat transfer effect of the condenser.

High and Low Pressure Switch: The high pressure switch is manual reset, and low pressure switch is auto reset.

Accumulator: The accumulator is a must to avoid liquid hammer.

Electric box: The electric box includes run capacitor, start capacitor and reply, increasing the start performance of the condensing unit.

What’s The Cooling Capacity Range of The Horizontal Condensing Unit?

Glen Refrigeration offers horizontal condensing unit with cooling capacity range from 0.75HP to 3 HP. Please click the models below to check the details.

GL-HSN7.5EL (3/4 HP condensing unit)

GL-HSN10EL (1 HP condensing unit)

GL-HSN15EL (1.5 HP condensing unit)

GL-HSN20EL (2 HP condensing unit)

GL-HSN25EL (2.5 HP condensing unit)

GL-HSN30EL (3 HP condensing unit)

What’s The Application of Horizontal Condensing Unit?

The horizontal condensing unit widely used in plug-in multidecks, meat display cabient, self-contained display cabinet, glass door upright freezer and so on.

What Should be Pay Attention To When Use The Horizontal Condensing Unit?

(1) Try to control the amount of the refrigerant charge volume, the quantity of refrigerant must be less than MAX.

(2) In order to ensure the oil return, when selecting the diameter of the suction pipe and evaporator, it should be ensured that the flow rate of the refrigerant gas reaches 3.8 m/s in the horizontal pipe and 7.6 m/s in the vertical pipe.

(3) In order to ensure the oil return, when installing the U type oil return bend of the evaporator, be sure to make the refrigerant pipeline slope downward.

(4) The length of pipe and height difference must be less than limit value.

(5) It is recommended to use an externally balanced expansion valve, and a solenoid valve must be installed.

(6) The rotary vane compressor is composed of high-precision parts. Please be careful not to mix dust, metal dust, oxide scale and other impurities when connecting.

| Model | GL-HSN7.5EL | GL-HSN10EL | GL-HSN15EL | GL-HSN20EL | GL-HSN25EL | GL-HSN30EL |

| Max Refrigerant Charge(KG) | 1.2 | 1.3 | 1.6 | 3.0 | 3.0 | 3.0 |

| Max Pipe Length (m) | 10 | 10 | 10 | 10 | 20 | 20 |

| Max Height Difference (m) | 3 | 3 | 3 | 5 | 5 | 5 |

What’s The Scope of Use Of The Horizontal Condensing Unit?

| Condensing Unit Series | GL-HSN Series |

| Refrigerant | R404A, R448A, R449A, R455A |

| Evaporating temperature | -45~-5°C |

| Suction pressure (Gauge pressure) | 0.008 ~ 0.420MPa |

| Suction temperature | ≤18°C |

| Suction super-heat | ≥10°C |

| Condensing temperature | Commonly used 30~60°C |

| Discharge pressure | Commonly used 1.1~2.50MPa |

| Exhaust gas temperature | ≤115°C |

| Oil temperature | ≤95°C (Ambient temperature +10°C above) |

| Ambient temperature | -7~43°C |

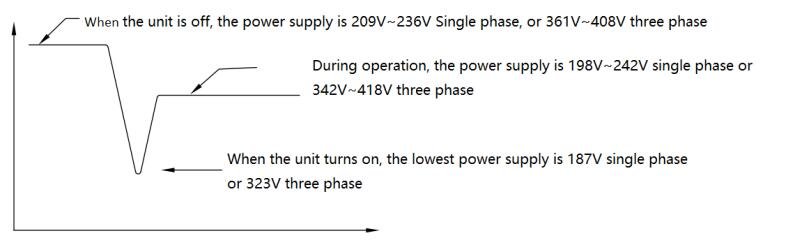

| Voltage | Single-phase 220V± 10% Three-phase 380V± 10% |

| Minimum voltage allowed at startup | Single-phase 187V Three-phase 323 V |

| Install place | Indoor |

The Measures Taken in Cold Region

When the horizontal condensing unit installation in cold areas (areas’ ambient temperature below 0°C during the day), in order to prevent the refrigerant from drifting into the compressor,when cabinet temperature is > ambient temperature, it is recommended to use the vacuum shutdown method when defrosting.

(1) Decrease pressure drop of the connecting pipe.

(2) Select an evaporator with sufficient capacity to increase the evaporating temperature.

(3) Clean the condenser regularly.

(4) Keep good ventilation around the condensing unit so that the temperature around the condensing unit is below 43°C。

What Should be Pay Attention To When The Horizontal Condensing Unit Installation?

(1) The condensing unit should be installed in a place which is easy to install, operate and inspect.

(2) It should choose the shortest connection pipe and wiring and easy to construct.

(3) The condensing unit needs daily maintenance, so please install it in a place where it is easy to maintain.

(4) Daily maintenance and inspection refers to the inspection of operating pressure, noise, sight-glass, filter dryer, electromagnetic contact and high and low pressure switches, fan motors and so on.

(5) Maintain good ventilation. Please install the condensing unit in a place below 43°C and easy to ventilate!

(6) The condensing unit should be level In order to prevent poor oil supply of the compressor lubricating oil, please install the condensing unit horizontally so that the inclination is within 3°C.

(7) The condensing unit should be moved vertically and stably, and it is not allowed to fall down!

(8) When transport the condensing unit, be careful to prevent the condensing unit (especially the compressor) from vibrating!

What Should be Pay Attention To When Vacuum The Horizontal Condensing Unit?

(1) Must evacuate the system in order to prevent air, moisture (Must use vacuum pump)

(2) Please VACUUM from high and low pressure sides of the condensing unit.

(3) Vacuum standard: After R404A unit reaches the absolute pressure 6.7 Pa, must VACUUM 1 to 2 hours again.

What Should be Pay Attention To When Charge the Refrigerant?

(1) Charge refrigerant from high pressure side after vacuum.

(2) If short of refrigerant, charging the gaseous refrigerant from low pressure side when the system is running. If the system is short of refrigerant, the temperature switch or the compressor motor thermostat will auto reset. The system must run over 1 minute after charging refrigerant 15 minutes.

(3) Fill the refrigerant until no air bubbles in the sight glass, and it should be not exceed the maximum amount. When the refrigerant charge volume is large, an receiver is required.

(4) The evaporator must be in the range of MAX. refrigerant. If R404A refrigerant charge not enough, the liquid injection is not enough; if overcharge, the oil will be diluted, causing damage to the sliding surface and liquid compression. For proper charging, must use a sight-glass to confirm.

What Should be Pay Attention To When Electric Wiring?

Prevent electric shock

(1) Please use a exclusive circuit!(Do not share with other products)

(2) Please install the ground wire!

(3) Please install a leakage protector(Leakage relay can’t protect)

(4) Do not let the wires touch the high temperature parts(Compressor, condenser, discharge pipe) and the edge of the metal.

Power supply range

The power supply of the condensing unit is allowed in this range, please keep operation in this range.

The measuring point is the power supply terminal of the condensing unit.

Please click here to download the “Air Cooled Indoor Condensing Unit Installation Manual” to learn more of the precautions for use.

Find The Right Condensing Unit or Monoblock Refrigeration Unit for your Commercial Refrigeration Equipment

Glen Refrigeration offers a wide range of condensing units and refrigeration units, including refrigerator condensing units, air cooled condensing units, water cooled condensing units, outdoor condensing units, monoblock refrigeration units and many others. Whether you need basic condensing unit, or a custom refrigeration solution, Glen Refrigeration will be able to cater to your business’ requirements. Our expertise and adaptability is what sets us apart from the crowd, give us a call to talk about the custom refrigeration system needs of your commercial refrigeration equipment.

Feel free to contact with us by Email or Whatsapp or fill out the contact form below.

Email:info@greehvacr.com

Whatsapp: 0086 15057108995