What is Filter Drier In Refrigeration System?

The filter drier is an refrigeration component in refrigeration system. It plays the role of drying and filtering, ensures the refrigerant is dry and free of impurities, so that improves the efficiency and lifespan of the refrigeration system.

What’s the Function of Filter Drier in Refrigeration System? Is a Filter Drier Necessary?

Yes, filter drier is necessary in air conditioning system and refrigeration systems. It has two main functions, that is drying and filtering.

Drying means remove the refrigeration system’s moisture. If there is moisture in air conditioning and refrigeration system, it will cause great harm to the system.

If there is moisture in the system, the water will freeze easily in the capillary or expansion valve, causing the cooling effect to decrease. The occurrence of TXV capillary tube freezing up or is mainly due to the excessive moisture contained in the refrigeration system. With the continuous circulation of the refrigerant, the moisture in the refrigeration system gradually concentrates at the outlet of the expansion valve. Because the temperature at outlet of the expansion valve is lowest, the water freezes into ice and gradually increases in size. To a certain extent, the expansion valve capillary tube is completely freezing up, the refrigerant cannot circulate, and the cooling effect decreases.

Filtering means filter out the impurities of refrigeration system. If the impurities enter into the refrigeration system, with the circulation of the refrigerant, it will enter into the refrigeration compressor pump body, causing abnormal scratches and wear on the friction surfaces of the moving parts. If impurities enter the solenoid valves, expansion valves, capillary tubes and stop valves in the air conditioning system and refrigeration system, they will block the valve holes or cause damage.

What Are The Main Components of A Filter Drier?

The main materials that work in the filter dryer are:

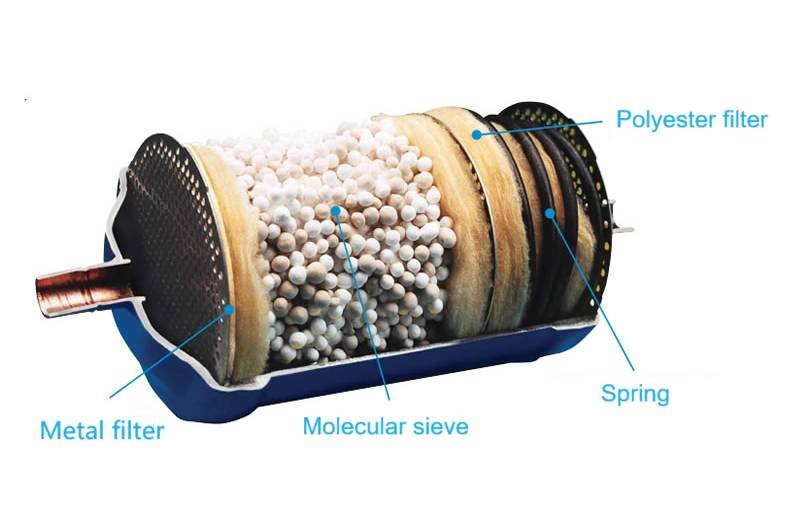

- Metal filter: filters out larger solid particles;

- Polyester filter: filters out tiny particles;

- Glass wool: filters out tiny particles;

- Molecular sieve: filters out larger solid impurities and absorb water. Molecular sieve’s ability of absorbing water is 3-4 times more than other substances, and it can also absorb acidic substances.

- Activated alumina: absorbs moisture, mainly acidic substances.

- Activated carbon: absorbs paraffin, but the refrigeration oil will only precipitate paraffin when the temperature is lower than -35 degrees, so it does not need to be used in high temperature refrigeration systems and medium temperature refrigeration systems.

The thread filter drier is made of componenets below: (From No.1 to No. 11)

- Rubber plug

- Thread cap

- Steel connector

- End cap

- Stamping piece

- Metal filter

- Polyester filter

- Glass wool

- Molecular sieve

- Shell

- Label

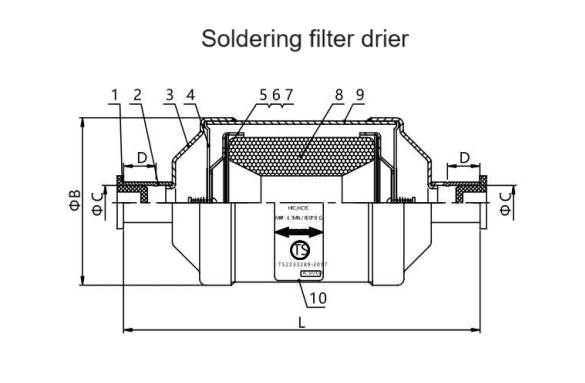

The soldering filter drier is made of components below: (From No. 1 to No. 10)

- Rubber plug

- Welding pipe

- End cap

- Stamping piece

- Metal filter

- Polyester filter

- Glass wool

- Molecular sieve

- Shell

- Label

Most of the filter drier is made of 100% molecular sieve or 80% molecular +20% activated alumina, so the filter drier also can be called molecular sieve filter drier.

What are Types of Filter Drier in Refrigeration System?

There are many types of filter driers in refrigeration system, including granular filter drier, solid core filter drier, a/c filter drier, refrigeration filter drier, heat pump filter drier, liquid line filter drier, suction line filter drier, hermetic filter drier filter drier shell and etc.

Solid core filter drier vs. Granular filter drier

According to filter drier core, the filter driers can be divided into solid core filter drier and granular filter drier. Their main differences are :

Molecular sieve filter drier: many small balls made of desiccant are filled in the drying filter.

Solid core filter drier: the desiccant is made into a hard filter element through a series of processes, and then installed in the dry filter.

A/C filter drier vs. Refrigeration filter drier vs. Heat pump filter drier

According to the application, the filter driers can be divided into a/c filter drier, refrigeration filter drier and heat pump filter drier.

The air cond filter drier used in air conditioning system, the purpose is to absorb the moisture and filter out the impurities of air conditioning system, ensuring the air conditioning running normally.

The refrigerator filter drier is also copper filter drier. It is a thick copper tube with a diameter of 16~18mm and a length of 100~180mm. Inside of the copper tube, there is metal filter and molecular sieve. The refrigerator filter driers can be divided into single inlet copper filter drier and double inlet copper filter drier.

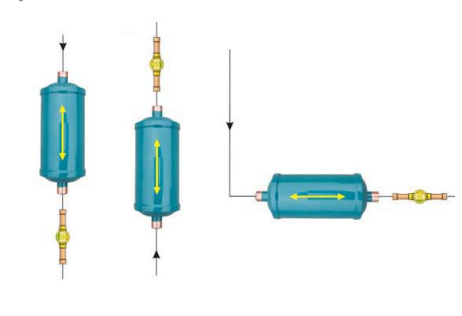

The heat pump refrigeration cycle provides both heating and cooling functions. So it needs a filter drier with two-way flow to absorb moisture and acid in the system and to filter out the impurities. The bi flow filter drier (also called bi-directional filter drier) has this function. They are with bi-flow or unidirectional flow, designed for heat pump application, hot gas defrost cycle. The bi flow filter drier has built-in check valves, which ensure liquid refrigerant always flows through filter driers from filter core’s outer side towards the center.

Liquid line filter drier vs. Suction line filter drier

According to the filter drier installation place, they can be divided into liquid line filter drier and suction line filter drier.

Liquid line filter drier is installed in liquid line of refrigeration system, the purpose is to protect the valve parts such as expansion valves, stop valves. It is a standard component in refrigeration systems. The liquid line filter drier location is between the receiver and expansion valve, usually followed by a sight-glass.

The suction line filter drier is installed in the suction line of the refrigeration system, close to compressor suction pipe, the suction line filter drier purpose is to protect the compressor. The suction filter drier is also called burn-out filter drier.

Hermetic filter drier vs. Filter drier shell

According to the filter drier structure, the filter driers can be divided into hermetic filter drier and filter drier shell.

Most of the filter driers used in air conditioning systems and refrigeration systems are hermetic filter driers. The core of hermetic filter drier is impossible to replace if it fails.

The filter drier shell is a replaceable core filter drier. The filter drier core can replace regularly. The replaceable filter shell is flange-connected and sealed, and is installed on the liquid line or suction line of the refrigeration system. It can effectively remove moisture and filter out the impurities, thereby it is better to protect the compressor; at the same time, it is more convenient to provide the maintenance after refrigeration equipment debugging and normal use.

What is Liquid Line Filter Drier? What does a Liquid Line Filter Do?

Liquid line filter drier is one of the most common filter drier in HVAC and refrigeration system. It is installed in liquid line of system. The liquid line filter drier purpose is to ensure the clean and dry refrigerant entering into the capillary or expansion valve. It mainly protects expansion valve, avoiding clogging of throttling device.

Where Is The Filter Drier Located In The Refrigeration System?

The liquid line filter drier is installed between the receiver and expansion valve, usually followed by a sight-glass. Please see below:

Which Direction does a Liquid line Filter Drier Go?

The arrow on the filter drier will point the flow direction. Most of the filter driers are one way filter drier.

The Bi-flow filter drier is designed for heat pump system, with double way flow directions. The filter drier has built-in check valves, which can ensure liquid refrigerant always flows through filter driers from the filter core’s outer side towards to the center. Thus all dirt particles are retained in either flow directions. And the filter driers can ensure quick and well adsorption of moisture, organic and inorganic acids.

How to Install A Liquid Line Filter Drier?

Pay attention to these points below during liquid line filter drier installation.

- The liquid line filter drier must be installed ahead of the component need to be protected; it is normally installed in the liquid line, before the expansion valve location.

- Glen Refrigeration recommends installing a sight-glass behind each filter drier to monitor drying effect.

- The arrow should be same as the liquid line filter drier flow direction.

- The filter drier can be installed in vertical mounting with downward flow or upward flow, but pay attention to these two points:

- Vertical mounting with downward flow: it takes a short time to evacuate or empty the system.

- Vertical mounting with upward flow: it takes a long time to evacuate or empty the system slowly as refrigerant must be evaporated out of the filter drier.

What is Suction Line Filter drier? What’s the Suction Line Filter Drier Purpose?

The suction line filter drier is also called burn-out filter drier, installed in the suction line to protect refrigeration equipment and the new compressor by adsorbing harmful acids after a compressor burn out.

Where is the Suction Line Filter Drier Located in the Refrigeration System?

The suction line filter drier is installed in the suction line. The installation place is as more closer to the compressor as possible.

What‘s the Difference of Suction Drier vs Liquid Line Drier?

The liquid line filter drier is installed in the liquid pipeline. The flow rate of the refrigerant in the liquid pipeline is very slow. At same time, the pressure drop of the filter dryer is also very small.

The suction line filter drier is installed in the suction line. Because the pressure drop of suction pipe has a greater impact on the system performance, in order to ensure that the pressure drop is as small as possible, the suction line filter drier sizing is generally larger than the liquid pipe drier (mainly referring to the flow capacity). And the filter drier for suction pipe is mainly used when the compressor is burned out, it will absorb a large amount of moisture, acidic substances or solid impurities in a short period of time. These things will reduce the circulation capacity of the filter dryer, thereby affecting performance, so there is usually an interface near the inlet and outlet of the suction line drier filter to test the pressure loss of the dry filter. If the measured inlet and outlet pressure difference exceeds the lower value, it must be replaced.

How to Install a Filter Drier in Suction Line?

Before suction line filter drier installation, please read the instructions thoroughly.

- Ensure to pump down the system and depressurize line before installation.

- Don’t remove the filter drier seal caps without installing it.

- The filter drier can be installed in horizontal position or vertical position. For best performance, the suction line filter drier installation as close as possible to the compressor inlet. Glen refrigeration suggest to install a suitable bracket to support the filter drier.

- The arrow should be same as the suction line filter drier flow direction.

- Use nitrogen when brazing to prevent formation of copper oxides.

- Use wet cloth to protect the filter drier when brazing, making the frame away from the filter drier shell.

We are committed to be your one-stop-shop of condensing units and refrigeration systems for commercial refrigeration.

If you have any questions about the commercial refrigeration cooling system, contact us by Email or fill out the contact form below, we are ready to help!

Email: info@greehvacr.com

Phone (Whatsapp): 0086 15057108995