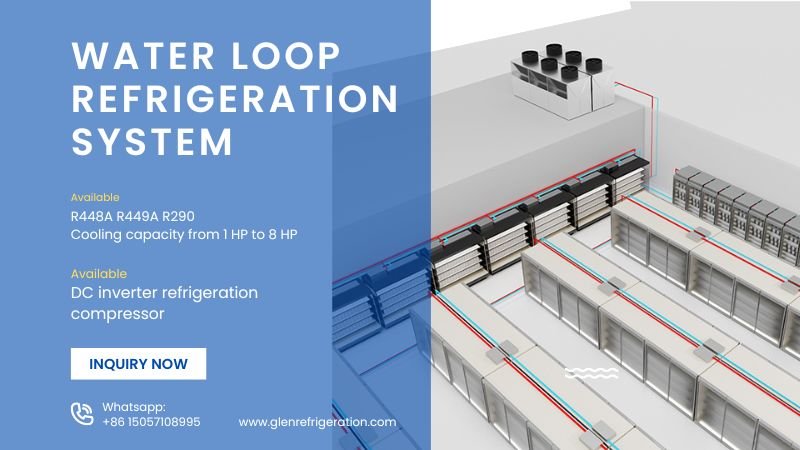

In recent years, commercial refrigeration market has successfully developed water loop refrigeration system. During the Chinashop 2023, the water loop refrigeration system has been demonstrated by many refrigeration companies, including fixed speed water cooled condensing unit and variable speed water cooled condensing unit. The variable speed refrigeration compressor is used in water loop refrigeration system, proved to has higher efficiency than traditional rack refrigeration systems.

Panasonic Cold Chain demonstrates the R290 water loop refrigeration system

Xiaoya Refrigeration demonstrates the water loop refrigeration solution

Traditional rack refrigeration systems are very large, generally installed in a equipment room or located on the rooftops of the building, supplying the refrigerant to the evaporators of showcases or cold rooms via long copper tubes.

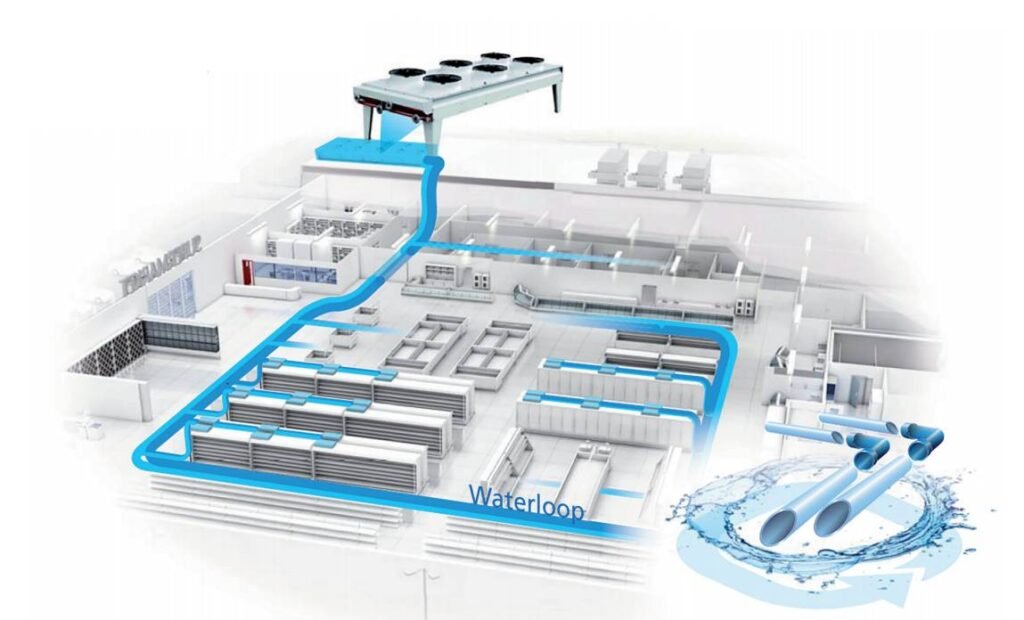

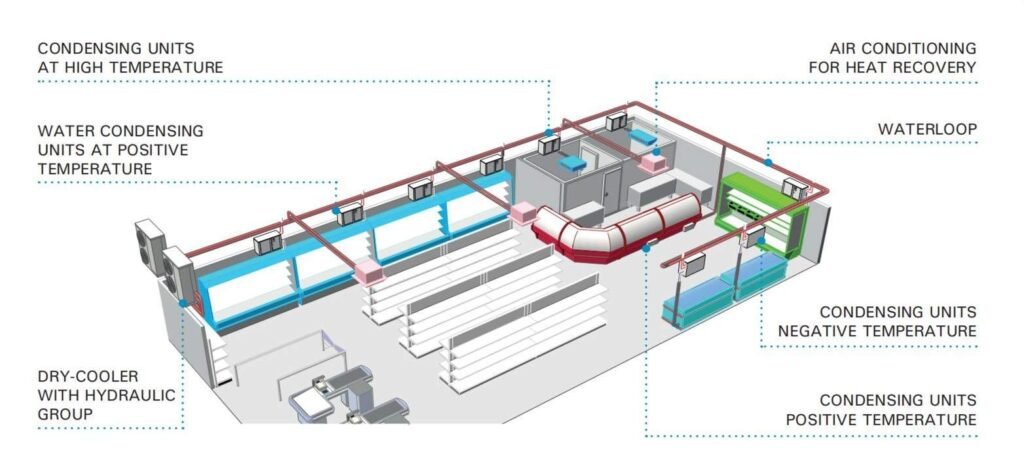

While the water loop system, acting as a distribution system by installing a small water cooled condensing unit into every displace case, and all units uses the same cooling water circuit, the water loop system rejects excess condensation heat through the liquid pipes to a dryer cooler outside of the building or through an heat recovery exchanger for building and water heating. This water loop refrigeration system can be connect to various commercial refrigeration equipment like multidecks, semi-verticals, serve-over counters, freezer cabinets and also cold rooms.

What is the Water Loop Refrigeration System?

The main parts of the water loop refrigeration system is the water cooled condensing unit, it is a dependant plugin condensing unit, installed in every displace case. It uses a plat heat exchanger to replace the air cooled fin tube heat exchanger. All units uses the same cooling water circuit connected to outdoor dry cooler or cooling tower.

The water loop system is a closed water loop system that remove the heat of condensation generated by the water cooled condensing unit. The water circuit carries heat away from the plate heat exchanger to the cooling tow or dry cooler. Then the dry cooler or cooling tower transfer the heat to the air.

What Does Water Loop Refrigeration System Composed of?

The water loop system, is composed of water cooled condensing unit, expansion valve, evaporator, water pump and the cooling tower.

Water cooled condenser unit: Glen Refrigeration offers water cooled condensing units with variable speed refrigeration compressor for commercial refrigeration water loop system, including compressor, brazed plate heat exchanger (water cooled condenser), receiver, accumulator, filter dryer and high & low pressure switch and controller.

Expansion valve: The expansion valve plays an important role in the refrigeration system, generally installed in front of the evaporator. The medium temperature and high pressure liquid refrigerant becomes a low temperature and low pressure steam through the expansion valve, then enters the evaporator to absorb heat and achieve cooling effect.

Evaporator: The evaporator is a kind of heat exchanger. The low temperature and low pressure refrigerant sent by the expansion valve is evaporated after absorbing the heat, so as to achieve the purpose of refrigeration. The water cooled condenser unit, expansion valve and evaporator compose a refrigeration cycle, can be installed by the showcase manufacturer on the production line. Customer only needs electrical and water supply to operate.

Water pump: Increase the water flow and circulation.

Cooling tower or dryer cooler: It is a device that use water as a circulating coolant to absorb heat from the refrigeration system cycle, reduce the water temperature, and allow the chilled water to continue to circulate.

What’s The Main Advantages of Water Loop Refrigeration System?

Compared with traditional rack refrigeration systems, there are several advantages of water cooling system with variable speed refrigeration compressor.

- High Efficiency and Energy Saving. Compared with rack refrigeration systems, the plugin water-cooled refrigeration systems feature high efficiency and energy saving. Each plug-in water cooled refrigeration unit is dependent, controlled by its cabinet temperature controller. When the setting temperature reaches, the variable speed DC compressor will work at a lower speed to maximum energy efficiency at part loads.

- Temperature Control More Precise and More Stable. In the traditional rack refrigeration systems or fixed speed compressor condensing unit, the cabinet temperature is unstable. When it turns on, the non-inverter compressor operates at 100% speed at all times until the cooling target temperature is reached, the compressor shuts down. It then turns on again when the cabinet temperature rises again-typically by a couple of degrees ℃. On and off, on and off…… It makes the cabinet temperature unstable and the temperature fluctuation range is above 4 ℃ . While the water cooled refrigeration condensing units with variable speed refrigeration compressor, it can adjust the compressor speed and refrigerant flow-rate according to different load, make the cabinet temperature control more precise and more stable. The cabinet temperature fluctuation range is only 1 ℃.

- Fast Installation and Lower Maintenance Costs. The plugin water cooled refrigeration system can be installed by the cabinet manufacturer. The refrigerant can be charged in the factory. Compared with traditional rack refrigeration systems, it requires less commissioning operations in the field, increases system reliability and lower maintenance costs.

- Less Refrigerant Charge and Less Leaks. In traditional rack refrigeration systems, it needs long copper pipes because of the long distance between the condensing units and the evaporators. Longer cooper pipes, more refrigerant needs. In the plugin water loop refrigeration systems, the water cooled condensing unit is installed on the rooftop of the refrigerated cabinet, so less refrigerant charge. Moreover, the refrigerant is pre-charged in the factory, each cabinet is tested on the production line, so the refrigeration system leaks can be reduced greatly.

Glen Refrigeration-Leading Water Cooled Condensing Unit Manufacturers In China

Glen Refrigeration is committed to takes the leading way in high efficiency and ECO friendly refrigeration systems. We offer R404A, R448A, R449A, R290 water-Cooled Condensing Unit for positive and negative temperature refrigeration, designed for quiet and high efficiency operation, that replaces the traditional layout of compressor racks and long refrigerant distribution lines. Condensation by a water circuit, the heat is carried by the water loop out of the system and rejected by a dry cooler typically placed on the roof. Synergic operation of DC inverter compressor and electronic expansion valve using intelligent control system brings exceptional results in terms of energy efficiency and quality of products preservation. This solution can be connected to various refrigeration equipment like multidecks, semi verticals, serve-over counters, freezer cabinets and also cold rooms.

Water-Loop Refrigeration System Benefits:

- Capital efficiency where higher cabinet cost off sets against lower plant costs for small to medium size stores.

- Installation efficiency due to simplicity of water loop.

- Easy layout change with simple disconnection of water pipes from refrigerated cabinets.

- Wider sales area as there is no more need for a machinery room for compressor racks.

- High investment recovery in case of store relocation.

- Gas leak reduction due to lower system charge and isolation.

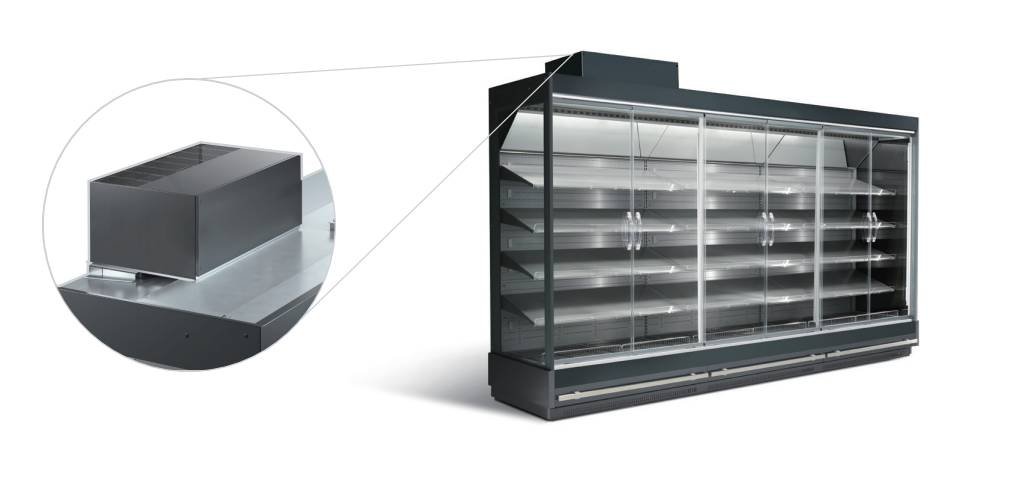

Low-profile Water Cooled Condensing Unit

The low-profile water cooled condensing unit adopts Sanyo R404A compressor, R290 compressor and inverter refrigeration compressor. The horizontal compressor with low-height and compact size, makes the water cooled condensing unit with low-profile, allows to optimize the useful space inside the cold room, guaranteeing excellent performance, reliability and efficiency.

R404a R448A R449A Low-profile Water Cooled Condensing Unit (220V~240V/50Hz)

| Model | Refrigerant | Power Supply | Cooling Capacity | Evaporating Temp. |

| GL-HSN10EL-SL | R404A, R448A, R449A | 220V~50Hz | 1 HP | -5°C~-40°C |

| GL-HSN15EL-SL | R404A, R448A, R449A | 220V~50Hz | 1.5 HP | -5°C~-40°C |

| GL-HSN20EL-SL | R404A, R448A, R449A | 220V~50Hz | 2 HP | -5°C~-40°C |

| GL-HSN25EL-SL | R404A, R448A, R449A | 220V~50Hz | 2.5 HP | -5°C~-40°C |

| GL-HSN30EL-SL | R404A, R448A, R449A | 220V~50Hz | 3 HP | -5°C~-40°C |

More details, please click here: Water-cooled Condensing Unit

R404a R448A R449A Low-profile Water Cooled Condensing Unit (220V~240V/50Hz)

| Model | Refrigerant | Power Supply | Cooling Capacity | Evaporating Temp. |

| GL-HSN10YL-SL | R404A, R448A, R449A | 220V~60Hz | 1 HP | -5°C~-40°C |

| GL-HSN15YL-SL | R404A, R448A, R449A | 220V~60Hz | 1.5 HP | -5°C~-40°C |

| GL-HSN20YL-SL | R404A, R448A, R449A | 220V~60Hz | 2 HP | -5°C~-40°C |

| GL-HSN25YL-SL | R404A, R448A, R449A | 220V~60Hz | 2.5 HP | -5°C~-40°C |

| GL-HSN30YL-SL | R404A, R448A, R449A | 220V~60Hz | 3 HP | -5°C~-40°C |

More details, please click here: Water-cooled Condensing Unit

R290 Low-profile Water Cooled Condensing Unit (220V~240V/50Hz)

| Model | Refrigerant | Power Supply | Cooling Capacity | Evaporating Temp. |

| GL-HSR10EL-SL | R290 propane | 220V~50Hz | 1 HP | -5°C~-40°C |

| GL-HSR15EL-SL | R290 propane | 220V~50Hz | 1.5 HP | -5°C~-40°C |

| GL-HSR20EL-SL | R290 propane | 220V~50Hz | 2 HP | -5°C~-40°C |

More details, please click here: Water-cooled Condensing Unit

Inverter Low-profile Water Cooled Condensing Unit

| Model | Refrigerant | Power Supply | Cooling Capacity | Evaporating Temp. |

| GL-BHSN10EL-SL | R404A, R448A, R449A | 220V~50Hz/60Hz | 1 HP | -5°C~-40°C |

| GL-BHSN20EL-SL | R404A, R448A, R449A | 220V~50Hz/60Hz | 2 HP | -5°C~-40°C |

| GL-BHSN30EL-SL | R404A, R448A, R449A | 220V~50Hz/60Hz | 3 HP | -5°C~-40°C |

More details, please click here: Water-cooled Inverter Condensing Unit

Low-profile Water Cooled Condensing Unit Photos

Copeland Water Cooled Condensing Unit

Glen Refrigeration offers Copeland water cooled condensing unit, adopting ZB series Emerson scroll compressor, ZF series Emerson scroll compressor, ZFI series Emerson scroll compressor for medium temperature refrigeration and low temperature refrigeration.

Copeland water cooled condensing units, characterized by high reliability and high efficiency, are usable in many different areas, like multidecks, semi verticals, serve-over counters, freezer cabinets, cold rooms and freezer rooms. They can be installed on the top of display cases, or cold rooms, and all units uses the same cooling water circuit connected to outdoor dry cooler or perform heat recovery.

ZB Series Compressor Copeland Water Cooled Condensing Unit

| Model | Refrigerant | Power Supply | Cooling Capacity | Evaporating Temp. |

| GL-GN20FM-SL | R404A, R448A, R449A | 380V~50Hz | 2 HP | -25°C to 5°C |

| GL-GN30FM-SL | R404A, R448A, R449A | 380V~50Hz | 3 HP | -25°C to 5°C |

| GL-GN35FM-SL | R404A, R448A, R449A | 380V~50Hz | 3.5 HP | -25°C to 5°C |

| GL-GN40FM-SL | R404A, R448A, R449A | 380V~50Hz | 4 HP | -25°C to 5°C |

| GL-GN50FM-SL | R404A, R448A, R449A | 380V~50Hz | 5 HP | -25°C to 5°C |

| GL-GN60FM-SL | R404A, R448A, R449A | 380V~50Hz | 6 HP | -25°C to 5°C |

| GL-GN70FM-SL | R404A, R448A, R449A | 380V~50Hz | 7 HP | -25°C to 5°C |

| GL-GN80FM-SL | R404A, R448A, R449A | 380V~50Hz | 8 HP | -25°C to 5°C |

| GL-GN90FM-SL | R404A, R448A, R449A | 380V~50Hz | 9 HP | -25°C to 5°C |

| GL-GN100FM-SL | R404A, R448A, R449A | 380V~50Hz | 10 HP | -25°C to 5°C |

More detail, please click here: Copeland Water Cooled Condensing Unit

ZF Series Compressor Copeland Water Cooled Condensing Unit

| Model | Refrigerant | Power Supply | Cooling Capacity | Evaporating Temp. |

| GL-GN20FLF-SL | R404A, R448A, R449A | 380V~50Hz | 2 HP | 7°C~-40°C |

| GL-GN30FLF-SL | R404A, R448A, R449A | 380V~50Hz | 3 HP | 7°C~-40°C |

| GL-GN35FLF-SL | R404A, R448A, R449A | 380V~50Hz | 3.5 HP | 7°C~-40°C |

| GL-GN40FLF-SL | R404A, R448A, R449A | 380V~50Hz | 4 HP | 7°C~-40°C |

| GL-GN50FLF-SL | R404A, R448A, R449A | 380V~50Hz | 5 HP | 7°C~-40°C |

| GL-GN60FLF-SL | R404A, R448A, R449A | 380V~50Hz | 6 HP | 7°C~-40°C |

| GL-GN70FLF-SL | R404A, R448A, R449A | 380V~50Hz | 7 HP | 7°C~-40°C |

| GL-GN80FLF-SL | R404A, R448A, R449A | 380V~50Hz | 8 HP | 7°C~-40°C |

| GL-GN100FLF-SL | R404A, R448A, R449A | 380V~50Hz | 10 HP | 7°C~-40°C |

More detail, please click here: Copeland Water Cooled Condensing Unit

ZFI Series Compressor Copeland Water Cooled Condensing Unit

| Model | Refrigerant | Power Supply | Cooling Capacity | Evaporating Temp. |

| GL-GN30FLI-SL | R404A, R448A, R449A | 380V~50Hz | 3 HP | -5°C~-40°C |

| GL-GN40FLI-SL | R404A, R448A, R449A | 380V~50Hz | 4 HP | -5°C~-40°C |

| GL-GN60FLI-SL | R404A, R448A, R449A | 380V~50Hz | 6 HP | -5°C~-40°C |

| GL-GN80FLI-SL | R404A, R448A, R449A | 380V~50Hz | 8 HP | -5°C~-40°C |

| GL-GN100FLI-SL | R404A, R448A, R449A | 380V~50Hz | 10 HP | -5°C~-40°C |

More detail, please click here: Copeland Water Cooled Condensing Unit

Copeland Water Cooled Condensing Unit Photo

Inverter Water Cooled Condensing Unit

DC inverter compressor and high efficiency water cooled condenser, with the intelligent inverter, make the water cooled condensing unit operated at optimal according to season.

| Model | Refrigerant | Power Supply | Cooling Capacity | Evaporating Temp. |

| GL-BSN30EL-SL | R404A, R448A, R449A | 220V | 3 HP | -5°C~-40°C |

| GL-BSN50FL-SL | R404A, R448A, R449A | 380V | 5 HP | -5°C~-40°C |

| GL-BSN70FL-SL | R404A, R448A, R449A | 380V | 7 HP | -5°C~-40°C |

| GL-BSN80FL-SL | R404A, R448A, R449A | 380V | 8 HP | -5°C~-40°C |

| GL-BMN100FL-SL | R404A, R448A, R449A | 380V | 10 HP | -5°C~-40°C |

More details, please click here: Water-cooled Inverter Condensing Unit

Are You Interested in Water Loop Refrigeration System?Do You Want To Learn More? Please click here: Water Cooled Refrigeration System

Free free to contact with us by email or Whatsapp or fill out the contact form below.

Email: info@greehvacr.com

Whatsapp: 0086 15057108995

We look forward to your inquiry!