What is A Liquid Line Solenoid Valve?

Liquid line solenoid valve is a kind of electromagnetic valve used to control the flow of the refrigerant. It is widely used in HVAC and refrigeration. It is also called refrigeration solenoid valve or refrigerant solenoid valve.

What’s the Liquid Line Solenoid Valve Application?

Solenoid valves are widely used in automation control systems, such as industrial automation control, air conditioning systems, refrigeration systems, automobile engines, agricultural irrigation systems and other fields.

The liquid line solenoid valve is one kind of solenoid valves, widely used in air conditioning and refrigeration system, used to control the flow of refrigerant when the compressor stops or works.

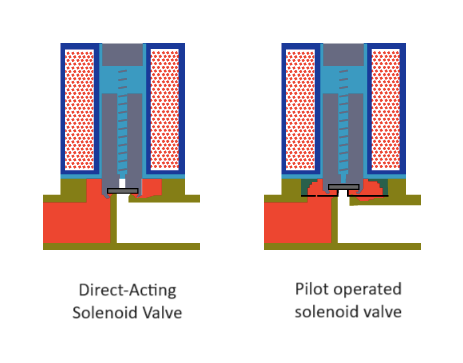

Is Liquid Line Solenoid Valve A Direct-Acting Solenoid Valve or an indirect acting solenoid valve?

The liquid line solenoid valve is a kind of direct acting valves.

According to the control mode, the solenoid valve can be divided into direct-acting solenoid valve and indirect acting solenoid valve. The liquid line solenoid valve is a direct acting valve, while the pilot operated solenoid valve is a indirect acting solenoid valve.

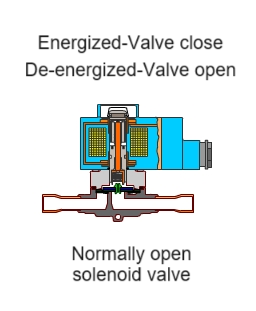

The direct-acting solenoid valve can be divided into normally open solenoid valve and normally closed solenoid valve. The liquid solenoid valve can also be divided into normally open liquid line solenoid valve (NO solenoid valve) and normally closed liquid line solenoid valve (NC solenoid valve).

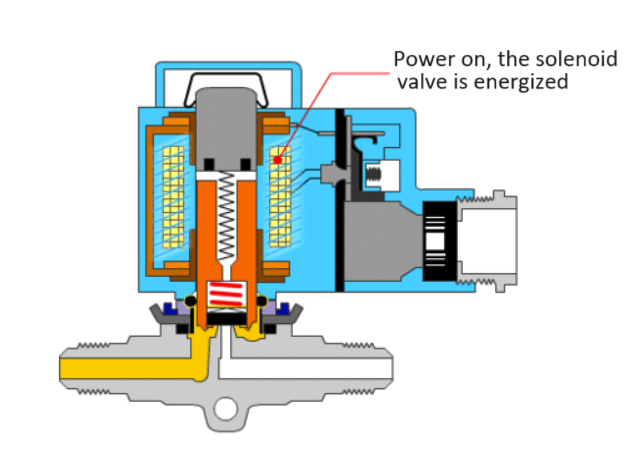

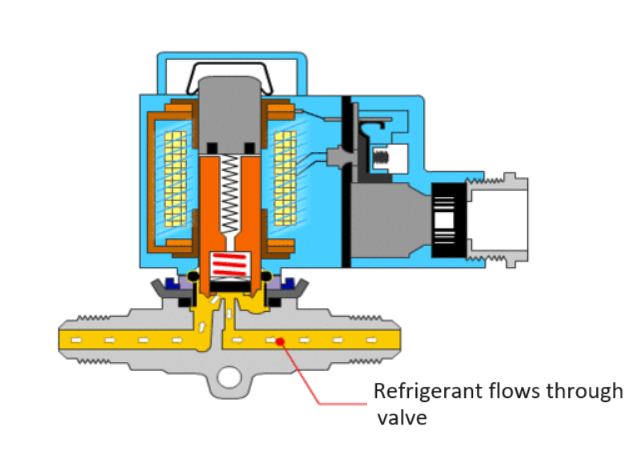

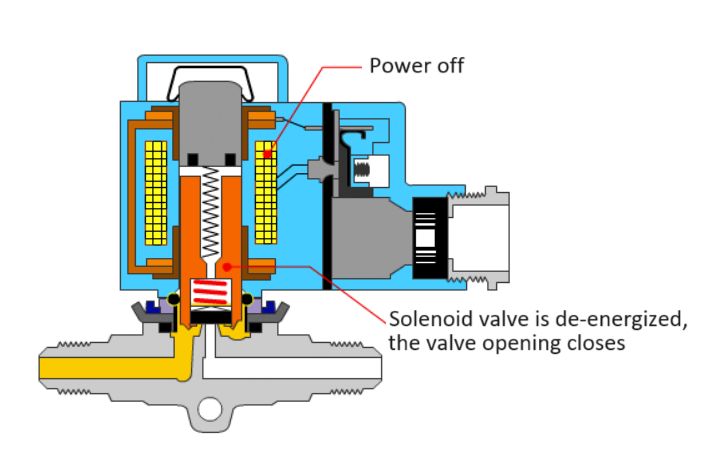

The normally closed solenoid valve’s work principle:

When the solenoid valve is de-energized, the solenoid valve is in a closed state. When the solenoid valve is energized, the current passes through the liquid line solenoid coil, there is a magnetic filed generated, making the iron core move upward, causing the valve opening to open. When de-energized, the magnetic field disappears, the iron core will bounce back to its original position and the valve will close accordingly.

What’s The Advantages of Liquid Line Solenoid Valve?

The liquid line solenoid valve, as a direct-acting solenoid valve, has the advantages:

- Simple structure

- High reliability

- Easy maintenance

- Fast response speed

- High accuracy

Is The Liquid Line Solenoid Valve Straight-through Solenoid Valve or Angle Solenoid Valve?

According to the valve structure classification, the solenoid valves can be divided into three types:

- Straight-through solenoid valve

- Angle solenoid valve

- Balanced solenoid valve

The straight-through solenoid valve means the refrigerant direction will not change when it flows the valve. The liquid line solenoid valve commonly used is a straight-through solenoid valve.

The solenoid valve used to control liquid injection is a angle solenoid valve. The inlet and outlet of the angle solenoid valve body are at a 90-degree right angle.

Is The Liquid Line Solenoid Valve Two Way Solenoid Valve?

According to the number of valve channels, the solenoid valve can be divided into:

- two way solenoid valve

- 3 way solenoid valve

- 4 way solenoid valve

- 5 way solenoid valve

- ……

Two way solenoid valve, 3 way solenoid valve, 4 way solenoid valve are common used in refrigeration systems.

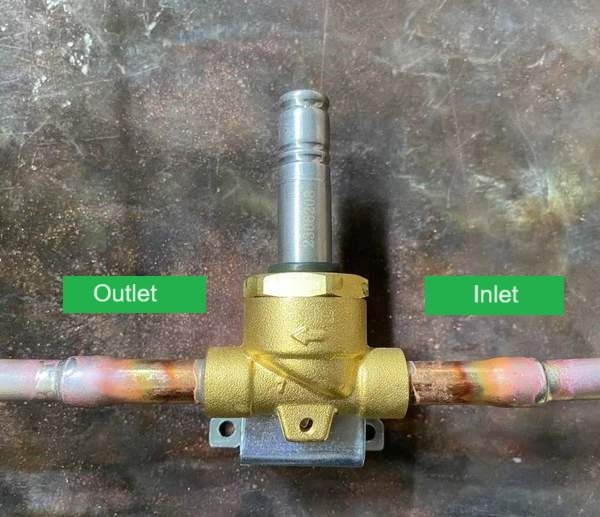

The liquid solenoid valve is a two way solenoid valve. Two way means there is two channels of the solenoid valve, one inlet and one outlet.

Where’s The Liquid Line Solenoid Valve Location?

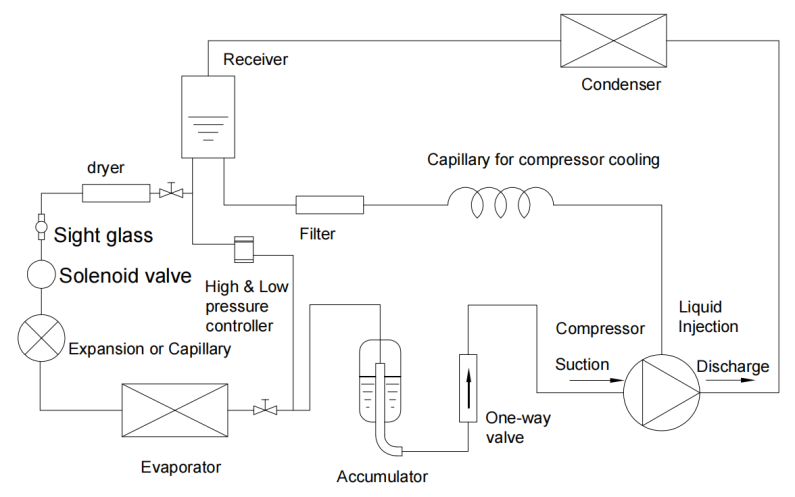

The liquid solenoid valve is installed before the expansion valve. The location of liquid solenoid valve should be as close as possible to the expansion valve, because the expansion valve is just a throttling device and can’t be closed tightly by itself, so a solenoid valve needs to be used to cut off the liquid supply pipeline.

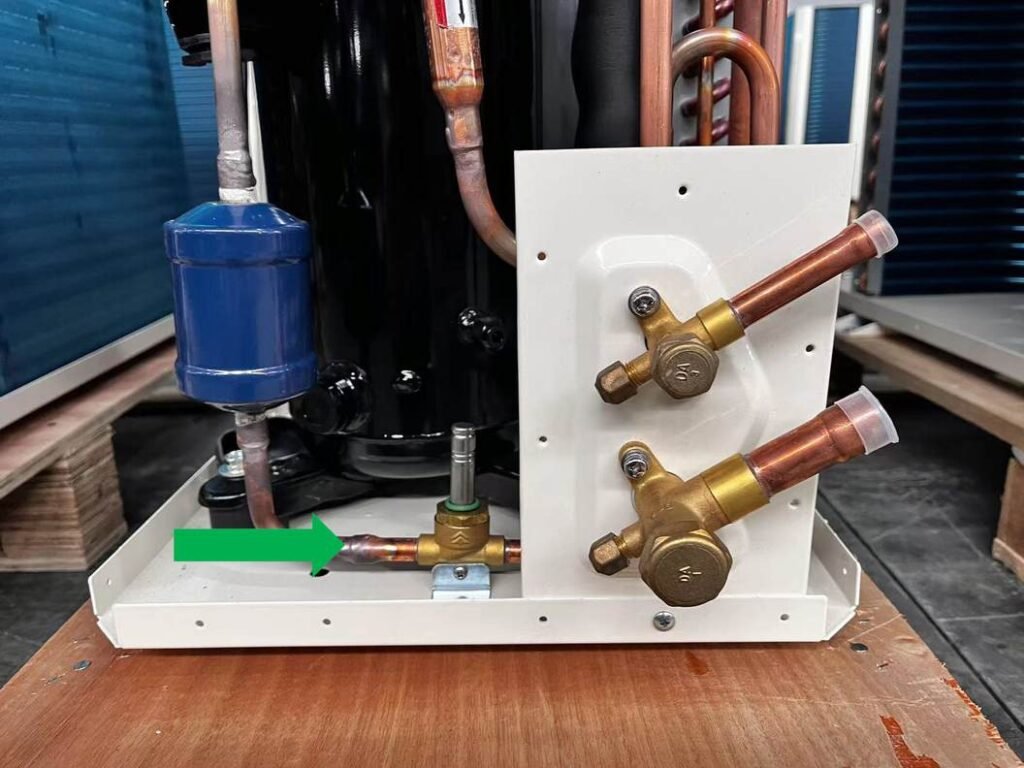

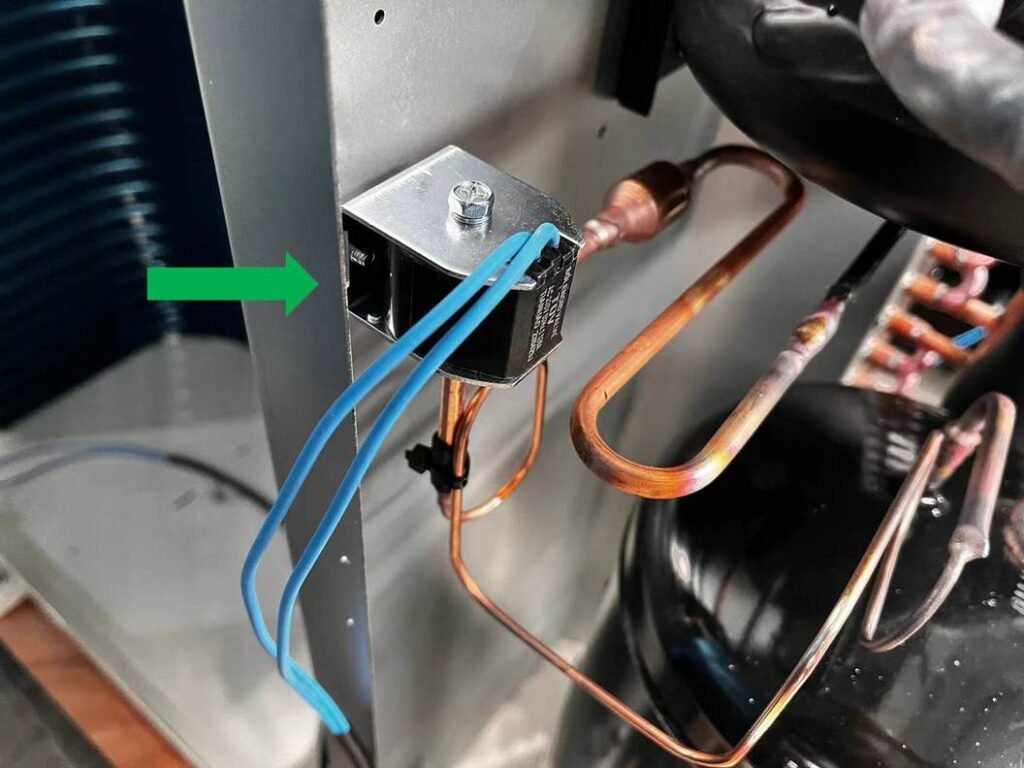

For smaller outdoor condensing unit 1 HP to 7 HP, we can offer the outdoor condensing unit with the liquid solenoid valve. The main advantages is convenient for our customers to use. But if our customers can install the liquid line solenoid valve on site, it is better. We will deliver the solenoid valve separately together with the unit.

For the outdoor condensing unit 8 HP and above 8 HP, we don’t install the solenoid valve, the liquid line solenoid valve will be as a component delivered together with the outdoor condensing unit, and need our customers to install on site. Because the refrigeration system pipeline is long, while the liquid line solenoid valve should be close to the thermal expansion valve.

What’s The Liquid Line Solenoid Valve Purpose?

The liquid line solenoid valve is used to cut off the high pressure part and low pressure part of the refrigeration system when powers off. The purpose of adding a solenoid valve in front of the expansion valve is to protect the compressor.

If there is no liquid line solenoid valve in the refrigeration circle, when the compressor stops, a large amount of liquid refrigerant will enter into the evaporator after the compressor stops. Therefore, the next time the compressor is started, the liquid in the evaporator can’t evaporate completely and the liquid refrigerant enters into the compressor, causing the compressor liquid hammer.

How Liquid Solenoid Valve Work in Refrigeration System?

When the refrigerated cabinet temperature reaches the set value, the temperature controller activates. At same time, the liquid line solenoid valve powers off and is closed, so the low pressure gets lower and lower. When low pressure reaches the shutdown set value, the refrigeration compressor stops.

When the refrigerated cabinet temperature rises again to reach the set value, the temperature controller operates. At same time, the solenoid valve powers on and is open, the low pressure rises and the high pressure and low pressure balances. When the low pressure reaches the set value, the compressor starts. (The temperature controller controls solenoid valve)

How To Install The Refrigeration Solenoid Valve In Refrigeration System?

The liquid line solenoid valve installation is very important.

First step, choose a right solenoid valve according to the refrigeration system pipeline, working conditions, power supply and etc.

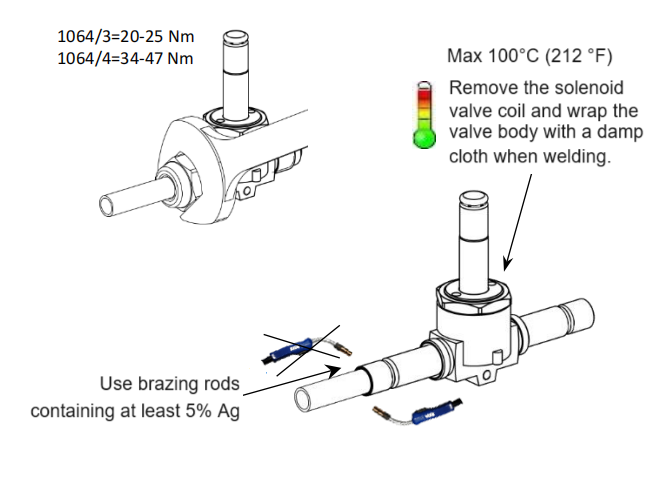

Second step, when welding solenoid valve, firstly remove the solenoid valve coil and wrap the valve body with a damp cloth, please see the picture below:

Pay attention: The solenoid valve must be installed vertically on the horizontal pipeline, with the solenoid coil on the top, the refrigerant flow direction is consistent with the arrow marked on the valve body.

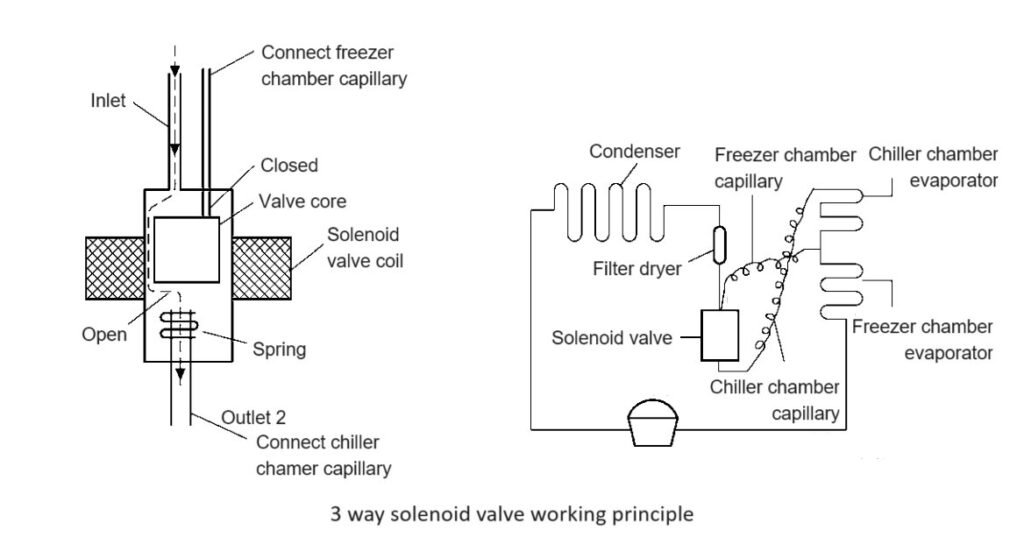

What is 3 Way Solenoid Valve?

The 3 way solenoid valve has three channels, one inlet and two outlets. It mainly commonly used in multi-temperature refrigerators.

The 3 way solenoid valve is also called 3 way 2 position solenoid valve. 2 position means the number of working positions of the solenoid valve. The solenoid valve 3 way 2 position means it has 3 channels and 2 working positions. Please see the 3 way solenoid valve working principle:

When the 3 way 2 position solenoid valve is energized, the magnetic core moves, blocks the capillary tube of the refrigerator compartment, connect the capillary tube of freezer compartment and refrigerant inlet. When the solenoid valve is de-energized, the magnetic core blocks the capillary tube of the freezer compartment, connect the capillary tube of the refrigerator compartment and refrigerant inlet.

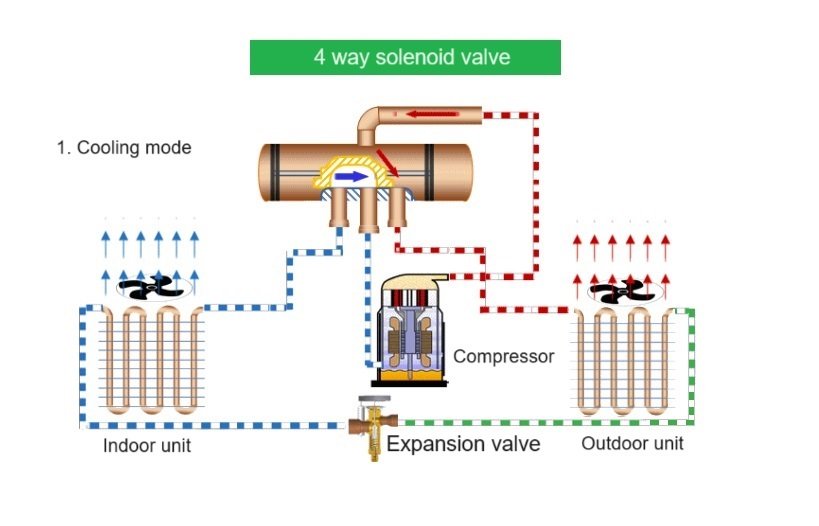

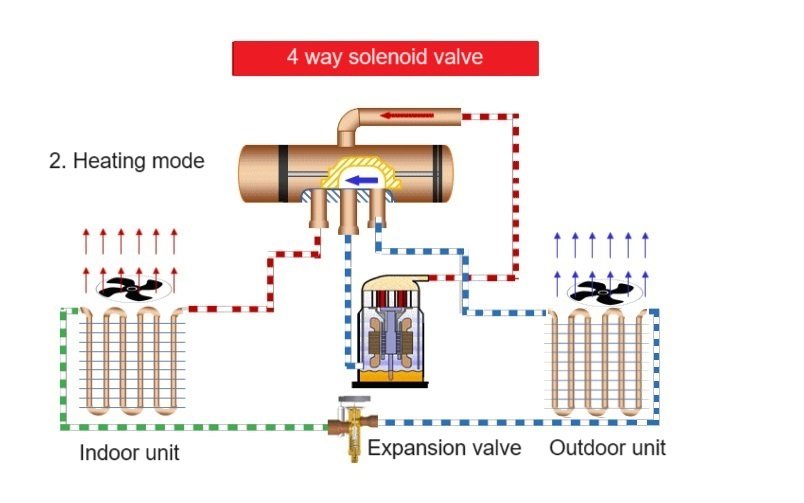

What is Four-Way Solenoid Valve?

The four-way solenoid valve is also called four-way reversing valve, it is mainly used in heat pump air conditioners, hot gas defrost refrigeration system. Since there are mainly four pipes connected to it in structure, it is often called a four-way valve.

What’s Four-Way Reversing Valve Function?

The function of four-way reversing valve is to change the functions of the two units of the air conditioner by changing the flow direction of the refrigerant in the system, and realize switching of cooling, heating or defrosting functions.

What’s Four Way Reversing Valve Diagram?

The electromagnetic four-way reversing valve is composed of two parts, one part is the electromagnetic guide valve and the other part is the four-way reversing valve. The four-way reversing valve is controlled by the electromagnetic guide valve.