What Is The Refrigeration Solenoid Valve?

The refrigeration solenoid valve is a kind of solenoid valve used in refrigeration system. The working of refrigeration solenoid valve is to control and regulate the flow of refrigerant.

The solenoid valves types can be divided into the following:

- Direct-acting solenoid valve

- Step-by-step direct-acting solenoid valve

- Pilot solenoid valve

- Piston type solenoid valve

- Diaphragm type solenoid valve

- Pulse solenoid valve

Direct-acting solenoid valves are generally used in commercial refrigeration. Refrigeration solenoid valve is a kind of direct-acting solenoid valve while pilot solenoid valve is a kind of indirect acting solenoid valve.

What Is Direct-Acting Solenoid Valve?

The direct-acting solenoid valve is a device that controls the flow of media (such as liquid, gas, etc.) through electromagnetic force. It consists of magnetic core, solenoid coil, valve body, seals and springs, etc. The solenoid valve used in refrigeration system is direct-acting solenoid valve. The pipe diameter generally are between 6-22mm.

What Are Direct-Acting Solenoid Valve Working Principle?

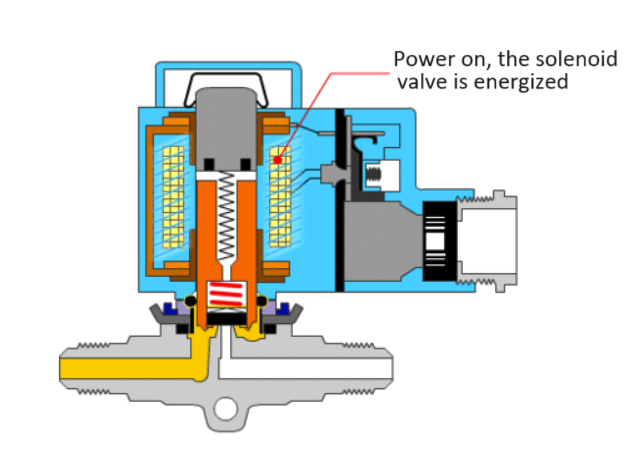

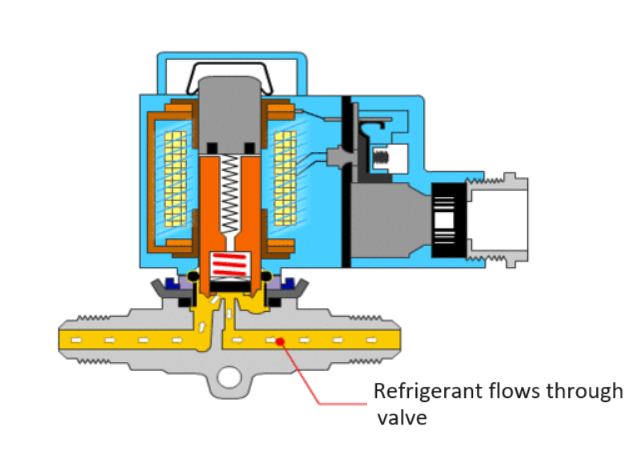

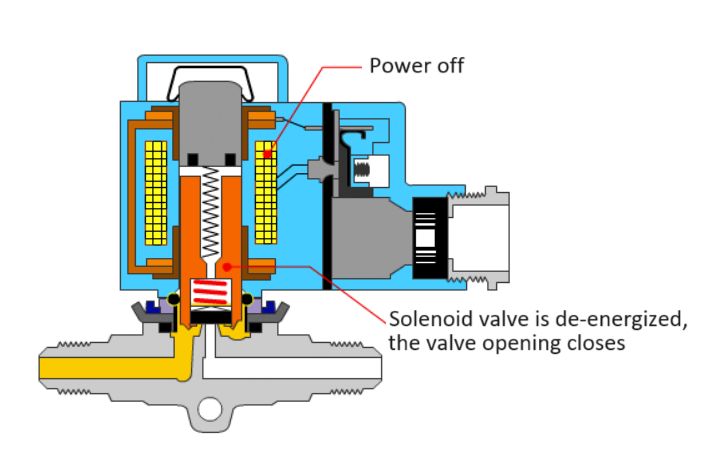

The solenoid valve is composed of magnetic core, solenoid coil, valve body, seals and springs, etc.

When the current passes through the solenoid coil, the coil generates a magnetic field. The magnetic field acts on the magnetic core to generate magnetic attraction. Then magnetic core moves toward the solenoid coil, causing the valve to open. When the solenoid coil is de-energized, the magnetic field disappears, the spring force returns the magnetic core to its original position, and the valve closes.

Please see the picture of solenoid valve working principle below:

The main points of direct-acting solenoid valve working principle:

- A solenoid valve is a control valve that utilizes electromagnetic force.

- It is an on/off valve that controls the flow of refrigerant based on power on and off.

- A refrigeration solenoid valve is an electromagnetic mechanical device used to control the flow of the refrigerant.

- The working state of the refrigerant solenoid valve is controlled by the current flowing through the coil.

- When the current passes through the coil, a magnetic field is generated, causing the magnetic core to move.

What Are Types of Direct-Acting Solenoid Valve?

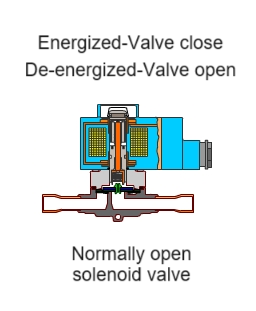

The direct-acting solenoid valve can be divided into normally open solenoid valve and normally closed solenoid valve.

Normally open solenoid valve is in an open state when the coil is de-energized. When the solenoid coil is powered on, the solenoid valve directly closes the valve port.

Normally closed solenoid valve is in an close state when the coil is de-energized. When the solenoid coil is powered on, the solenoid valve directly opens the valve port. The liquid pipe solenoid valve, liquid injection solenoid valve, oil return solenoid valve we used in refrigeration system are all normally closed solenoid valve.

What’s The Difference Between Normally Open vs Normally Closed Solenoid Valve?

The direct-acting solenoid valve has two types, normally open solenoid valve and normally closed solenoid valve. Please see the main difference of solenoid valve normally open or closed below:

| Solenoid valve | When the solenoid valvecoil is energized | When the solenoid valve coil is de-energized |

| Normally open solenoid valve | In a closed state | in an open state |

| Normally closed solenoid valve | in an open state | In a closed state |

What Are Common Types of Solenoid Valve In Refrigeration System?

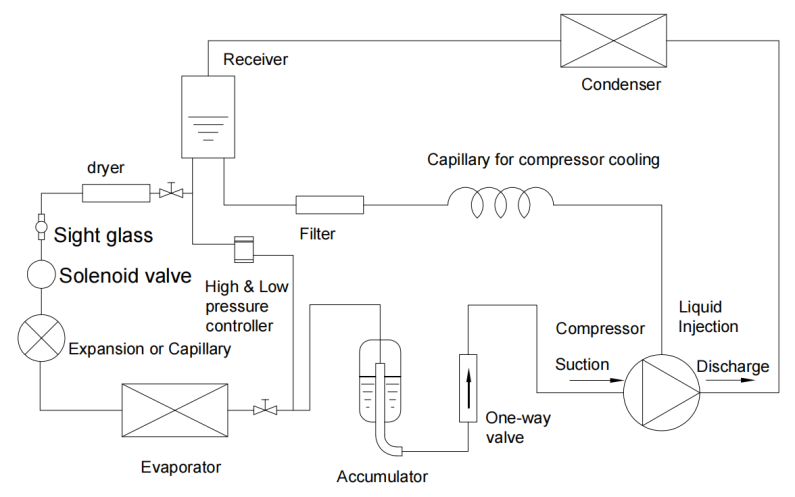

In outdoor condensing unit, the commonly used refrigeration solenoid valves include liquid line solenoid valve, liquid injection solenoid valve and oil return solenoid valve.

What Is The Liquid Line Solenoid Valve and Where’s The Liquid Line Solenoid Valve Location?

The liquid line solenoid valve is a refrigeration solenoid valve, that installed in the liquid refrigerant pipe of the refrigeration system. It is installed before the expansion valve. The more close to the expansion valve, the better.

For 1HP~7HP outdoor condensing unit, we offer the condensing unit with expansion valve, the advantages of the liquid solenoid valve installing inside the condensing unit is convenient for our customers to use. But if our customer can install the liquid line solenoid valve on site, that’s better.

For the 8 HP and above 8 HP outdoor condensing unit, the liquid line solenoid valve is not installed on the inside of outdoor condensing unit. Because the system pipeline is long.

Here is the Horizontal condensing unit with liquid line solenoid valve:

What’s The Liquid Line Solenoid Valve Function In Refrigeration System?

The liquid line solenoid valve for HVAC and refrigeration plays an important role.

The purpose of installing the liquid line solenoid valve in refrigeration system is to prevent the high-pressure liquid refrigerant from entering into the evaporator when the compressor shuts down, avoiding the low pressure over-high when the compressor starts next time and prevent the compressor liquid shock.

The refrigeration system is divided into high pressure and low pressure. If without the refrigeration solenoid valve, when the compressor is shut down, the high-pressure liquid refrigerant will migrates to evaporator from condenser and receiver, so there will be a large amount of liquid refrigerant in the evaporator. While the compressor restarts, the liquid refrigerant can’t evaporate completely, resulting that the cooling effect is not good and also causing liquid shock in the compressor.

That’s the liquid line solenoid valve purpose in commercial refrigeration system. In order to effectively preventing the large amount of high-pressure liquid refrigerant entering into evaporator and causing liquid shock to the refrigeration compressor, a refrigeration solenoid valve is installed to protect it. If the high pressure and low pressure is in a balance state before the compressor starts, there will be no liquid shock.

How Liquid Solenoid Valve Work in Refrigeration System?

When the cold storage temperature reached the set value, the temperature controller activates. At this time, the refrigeration solenoid valve de-energized and the low pressure gets lower. When it reaches the shutdown set value and the compressor stops down.

When the temperature in the cold storage rises again to reach the set value temperature, the temperature controller operates. At this time, the solenoid valve is energized. The low pressure rises and the high pressure and low pressure balances. When the low pressure reaches the set value, the compressor starts. (The temperature controller controls solenoid valve)

How To Install The Refrigeration Solenoid Valve In Refrigeration System?

The liquid line solenoid valve installation and how to replace a solenoid valve are very important.

First step, choose a right solenoid valve.

According to the refrigeration system pipeline, the solenoid valve diameter should be configured with the same size as the pipeline. For example, there is

- 3/8”solenoid valve

- 1/4” solenoid valve

- 1/2”solenoid valve

- 5/8”solenoid valve

- 3/4”solenoid valve

- ……etc.

The material of the solenoid valve body should be compatible with the medium in the center of the pipeline. There is:

- Copper solenoid valves

- Stainless steel solenoid valves

The solenoid valve used in refrigeration system generally are copper solenoid valve.

The working voltage should be consistent with the power supply voltage. Because there are different voltages, like

- 220V solenoid valve

- 100V solenoid valve

- 110V solenoid valve

- 12V solenoid valve

- 24V solenoid valve

- ……etc.

Choose the solenoid valve according to the working locations or applications, For example, the refrigerant solenoid valve cannot be used as a water solenoid valve, because the water will scale and inevitably contains solid impurities, which can easily block the small balance hole on the diaphragm. The suction line solenoid valve should have a moisture-proof coil or a closed solenoid valve because the temperature of suction pipe is low and it is easy to condense.

Second step, when welding solenoid valve, firstly remove the solenoid valve coil and wrap the valve body with a damp cloth, please see the picture below:

Third step, when installing, please pay attention to the liquid line solenoid valve direction.

Please note that the arrow on the valve body should be consistent with the flow direction of the medium. The liquid line solenoid valve cannot be installed installed backwards or downward. The solenoid valve body must be fixed on the unit or bracket to avoid vibration and system leakage.

If liquid line solenoid installed backwards, the refrigerant will not flow normally and the solenoid valve will not work properly.

What Are Other Types of Solenoid Valve in Refrigeration System?

Except the liquid line solenoid valve, there are other types of refrigeration solenoid valve, includes the liquid injection solenoid valve and oil return solenoid valve.

What Is Liquid Injection Solenoid Valve?

The Liquid Injection Solenoid Valve is used to control the liquid injection ON and OFF.

What Is The Function Of Liquid Injection Solenoid Valve?

When the refrigeration load increases, the compressor power increases, the discharge temperature increases accordingly, causing the refrigeration performance and lubricating oil to decrease, the compressor efficiency and reliability decrease accordingly.

In order to ensure the normal operation of the compressor and refrigeration system, the refrigerant from the receiver can be directly sprayed into the compressor suction pipe or compression chamber to reduce the temperature of the compressor motor, which is called liquid injection cooling.

The liquid injection solenoid valve is installed liquid injection pipe to control the liquid injection ON and OFF. When the condensing unit detects that the discharge temperature of the compressor is higher than the set value, the liquid injection solenoid valve opens, and the super-cooled liquid from the receiver is sprayed into the compressor chamber after passing through capillary throttling, thereby achieving the purpose of reducing the discharge temperature.

When the discharge temperature is lower than the compressor limit, the liquid injection solenoid valve closes.

Emerson Copeland ZF compressor operates with liquid injection through DTC valve in order to control the discharge temperature.

What Is Oil Return Solenoid Valve?

The oil return liquid injection is used to control the flow of oil return. It is installed between the oil return connector and the oil separator.

What’s the Function of Oil Return Solenoid Valve?

The function of oil return solenoid valve is below:

- Used to control the flow of oil return to compressor.

- Used to prevent the refrigerant flowing from high-pressure side to low-pressure side because the oil separator valve is poor air tightness sometimes.

Except the liquid line solenoid valve and liquid injection solenoid valve, there is other refrigeration solenoid valves in refrigeration system, like:

- Angle solenoid valve

- 4 way solenoid valve

- 3 way 2 position solenoid valve