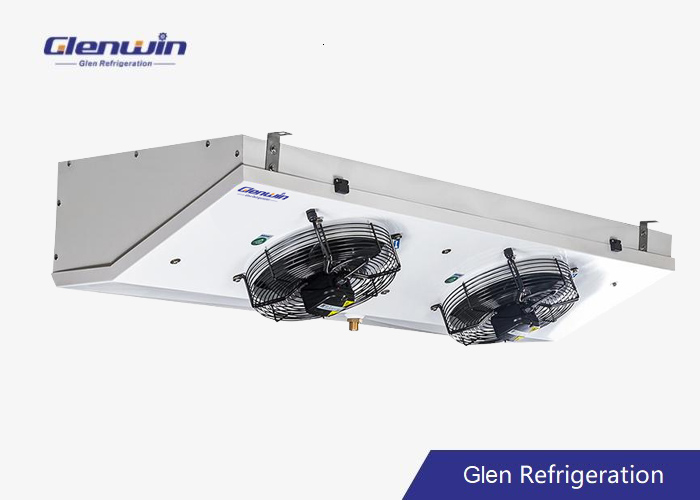

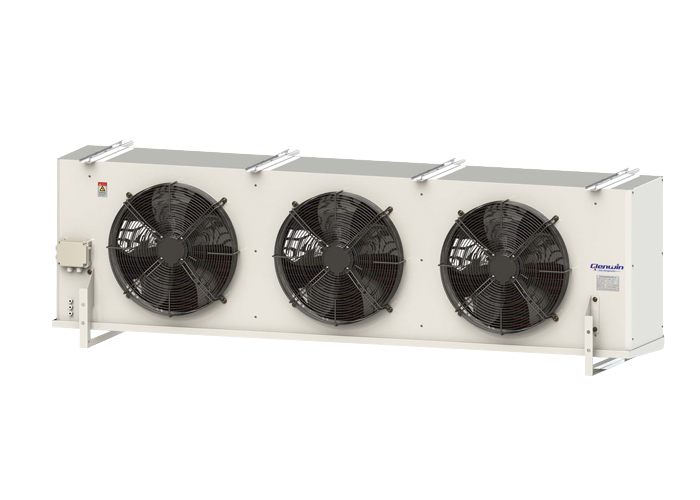

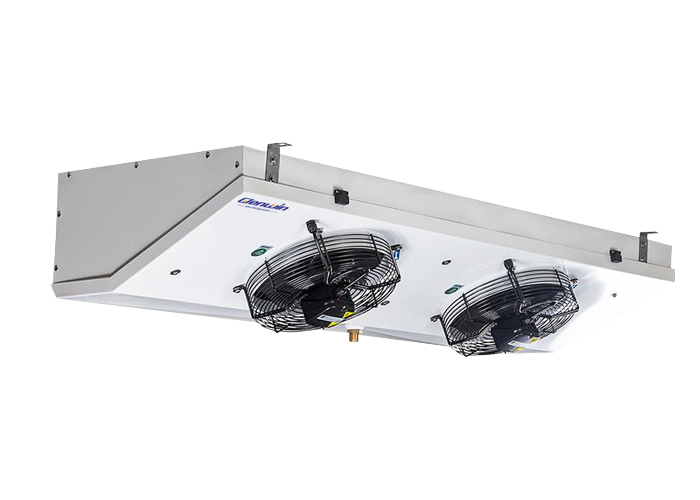

Air Cooler Evaporator for Cold Storage

Glen Refrigeration designs and manufactures Air Cooler Evaporator matched with refrigeration condensing unit for cold room and freezer room.

- Slim type air cooler evaporator

- Double flow air cooler evaporator

- Commercial cubic air cooler evaporator

Previous

Next