Why Is My Walk In Freezer Evaporator Coil Freezing Up?

The evaporator coil in the cold storage refrigeration system often works in a low-temperature and high-humidity environment. When the evaporator’s surface temperature is lower than the temperature of the cold room, the moisture in the air inside of the cold room will frost or freeze on the surface of the evaporator. The frost layer will affect the heat transfer effect of the evaporator, lower the efficiency of the refrigeration system and eventually cause it to become ineffective. So it needs to defrost regularly.

Defrost meaning use difference defrosting methods to remove the frost and ice from the surface of the evaporator coil, improving the efficiency of the evaporator to exchange heat.

What are the Main Defrosting Methods In Refrigeration System?

There are different defrosting methods in refrigeration, including manual defrosting method, off cycle defrost, electric defrost, water spray defrost, and hot gas defrost. The electric defrost and hot gas defrost are two main defrosting methods in walk in freezer.

- Electric defrost

- Hot gas defrost

What Is Electric Defrost Refrigeration System?

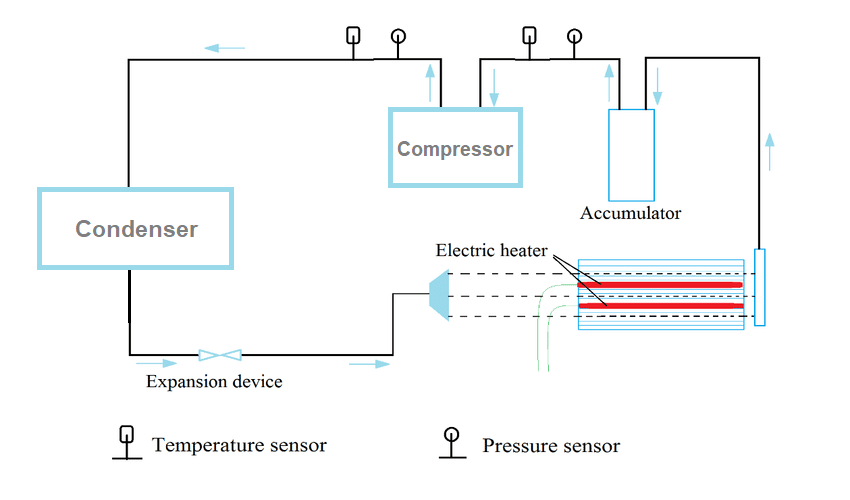

Electric defrosting methods use electric heating tubes to melt the frost and ice on the surface of the evaporator coil and fins. The electric heating tube is made of stainless steel and filled with magnesium oxide. They are inserted into the middle of the evaporator and also mounted on the surface of the water pan. In order to remove the frost as quickly as possible, the power of the electric heating tube is in the range of several kilowatts. Please see the pictures below:

Electric defrosting is one of the most common defrosting methods in commercial refrigeration evaporator coil and walk in freezer evaporator coil.

How Does Electric Defrost Work?

During electric defrost, the electric heating tubes transfer the heat to the evaporator to melt the frost or ice, the frost on the evaporator coil and fins melts into water, then drips into the water drain pan. The electric heating tube in the drain pan heats and evaporates it.

The operation of electric heating tubes generally adopts electronic defrost control of the electric box. For electric defrost, the most important is the defrost cycle and time setting. Proper defrost cycle and time settings can maintain the efficiency and temperature control of the walk in freezer.

What’s the Advantages of Electric Defrost?

The advantages of electric defrost is simple to easy to implement.

What’s the Disadvantages of Electric Defrost?

Low efficiency. The electric heating tubes are inserted into the middle of the evaporator, they don’t contact with the frost or ice directly. During electric defrost process, part of the heat is transfer to the evaporator coil and fins to melt the frost; the rest of the heat is transferred to the inside of the cold room or walk in freezer, becoming an additional load of the refrigeration system. When the refrigeration system resumes operation after a defrost period, this additional heat must be removed.

Long defrost cycle. Since the electric defrost system is not efficient, it needs long defrost cycle to melt the frost and ice completely. Because if the frost and ice are not melted completely, they will condense into ice again, reducing the cooling effect. But if the freezer defrost cycle too long, it will result the large fluctuation of room temperature and also increase the energy consumption.

Temperature fluctuates largely. In order to defrost as quickly as possible, the power of the electric heating tube is in the range of several kilowatts, so the electric heating tube will generate lots of heat. Moreover, only part of the heat is transfer to the evaporator coil and fins, another part of the heat is transfer to the cold room, at same time, because of long defrost cycle, they all results in the cold room temperature fluctuates largely.

High energy consumption. Firstly, the power input of electric defrost heaters of a single evaporator is very high; secondly, only part of the heat is used to melt the frost and ice, another large part of the heat results in the cold room temperature increasing. After the defrost cycle, it needs more cooling and takes longer time to reduce the cold room temperature.

What Is Hot Gas Defrost?

The hot gas defrost method uses the superheated vapour gas discharged from the compressor to melt the frost and ice. There are two different kinds of hot gas defrost, including hot gas bypass defrost and reverse cycle defrost.

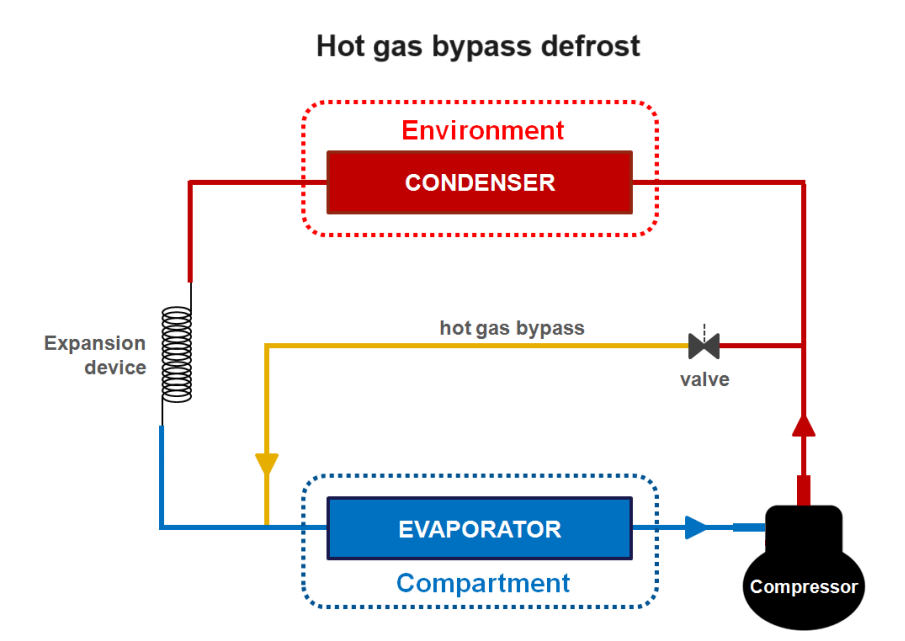

What Is Hot Gas Bypass Defrost?

Hot gas bypass defrost provides a method to bypass the high-temperature gaseous refrigerant at the high-pressure end to inlet of the evaporator to melt the frost and ice. It is one kind of hot gas defrost methods in refrigeration.

How Does a Hot Gas Bypass Defrost System Work?

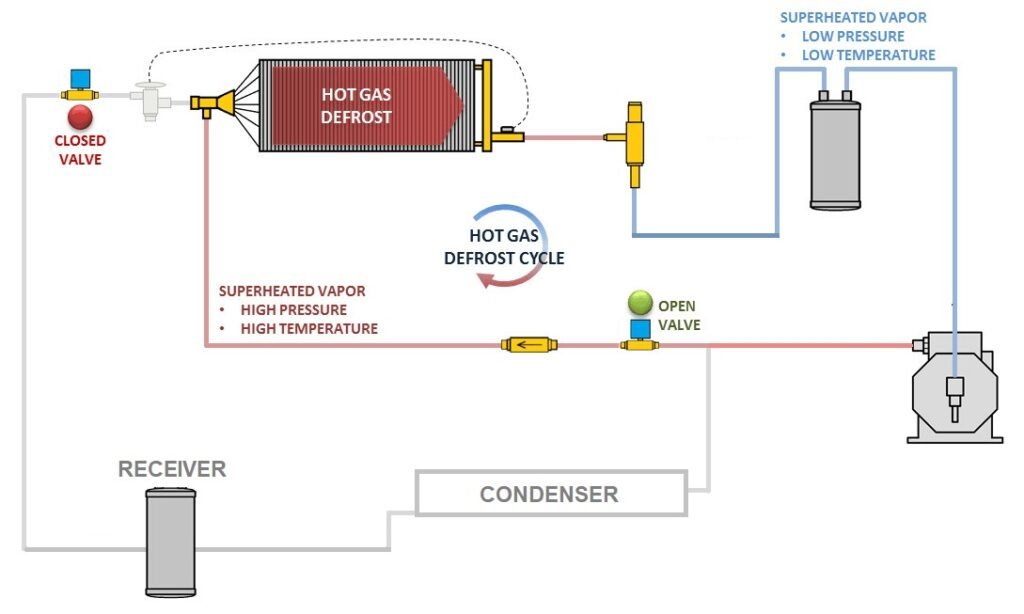

To make hot gas bypass defrost method working, a bypass piping and hot gas bypass valve (solenoid valve) are added between the compressor discharge and evaporator inlet. The compressed high-pressure and high-temperature refrigerant vapour reaches the evaporator directly through the bypass piping.

During the refrigeration cycle, the solenoid valve of the hot gas defrost piping is closed, the compressed high-pressure and high-temperature refrigerant vapour flow to the condenser to perform the stand cooling circuit.

When the hot gas defrost works, the solenoid valve opens, the superheated vapour is released from the compressor discharge and flow through hot gas defrost piping to the evaporator directly. It condenses in the evaporator and melt the frost and ice. Please see the hot gas bypass defrost cycle diagram below:

Top Mount Monoblock Refrigeration Unit

Top mount monoblock refrigeration unit, with hot gas bypass defrost, provides a high efficient and energy-saving defrost method for commercial freezer.

Side Mount Monoblock Refrigeration Unit

Side mount monoblock refrigeration unit, with hot gas bypass defrost, provides a efficient and energy-saving defrost method for worktop freezer.

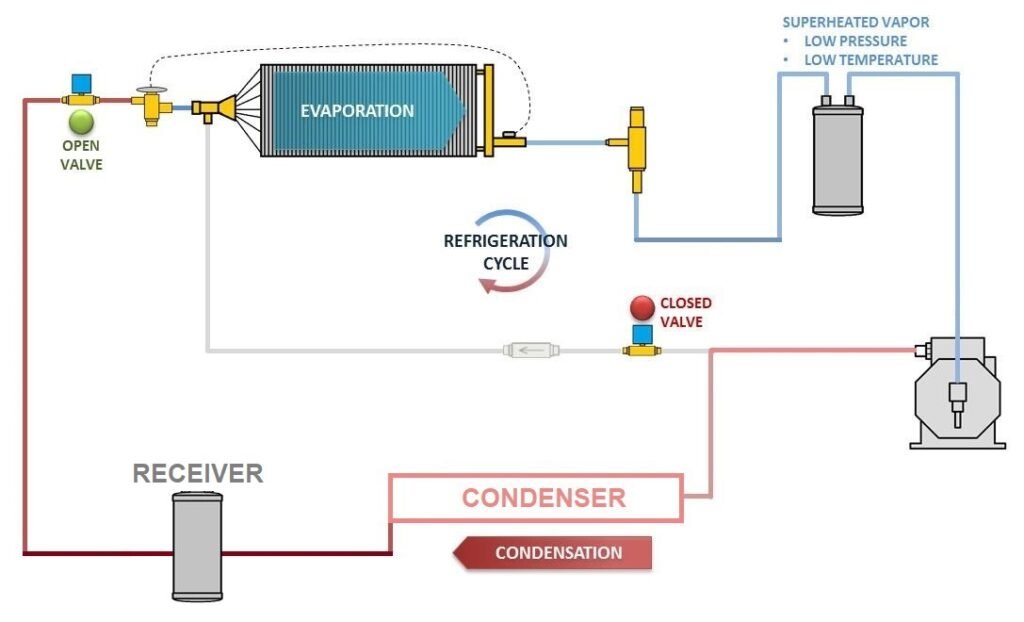

What Is Reverse Cycle Defrost?

As it’s name implies, the reverse cycle defrost method needs to change the the refrigeration system cycle. To make reverse cycle defrost method working, a four-way solenoid valve is added. At same time, Bi-flow filter drier and Bi-flow receiver are needed. The reverse cycle hot gas defrost system consists of refrigeration compressor, condenser, Bi-flow filter drier, Bi-flow receiver, sight-glass, four-way solenoid valve, evaporator, accumulator and other refrigeration parts. The reverse cycle defrost is the opposite operation of the refrigeration cycle. Please see the reverse cycle hot gas defrost diagram below:

How Does a Reverse Cycle Defrost Work?

The reverse cycle defrost is the opposite operation of the refrigeration cycle. The reverse cycle defrost is actually a heating cycle. In winter, the evaporator acts as a condenser, the high-temperature high-pressure vapor refrigerant discharged from the compressor, flows into the evaporator to perform heat exchange.

The reverse cycle defrost is realized through a four-way solenoid valve. During defrost, the four-way valve operates, causing the refrigeration system to change from a refrigeration cycle to a heating cycle. At the same time, the evaporator fan stops working, and the high-temperature gas enters into the evaporator for defrost.

Please see the refrigeration cycle below:

Please see the reverse cycle defrost below:

Wall Mounted Monoblock Refrigeration Unit

Wall mount monoblock refrigeration unit, with reverse cycle hot gas defrost, suitable for small and medium size cold room and freezer room.

Ceiling Mounted Monoblock Refrigeration Unit

Ceiling mount monoblock refrigeration unit, with reverse cycle hot gas defrost, suitable for small and medium size cold room and freezer room.

What’s The Different Between The Hot Gas Bypass Defrost vs. Reverse Cycle Defrost?

Both of hot gas bypass defrost and reverse cycle defrost use hot gas to melt the frost or ice of the evaporator coil and fins. But there are some differences.

The hot gas bypass defrost don’t change the refrigeration cycle. It perform defrost by a bypass pipe and a hot gas bypass valve.

While the reverse cycle defrost needs to change the refrigeration cycle when defrost. It changes the refrigeration cycle to a heating cycle by the four-way solenoid valve.

What’s The Advantages of Hot Gas Defrost?

High efficiency. High efficiency is the main advantage of hot gas defrost. Because the high gas passes the entire evaporator coil, most of the heat is transferred to the evaporator coil and fins directly. For electric defrost, only part of the heat is transferred evaporator coil and fins. So hot gas defrost has higher efficiency than electric defrost.

Short defrost cycle. In hot gas defrost systems, the refrigerant vapour is already hot when the hot gas defrost cycle begins. And the hot gas passes through the whole evaporator coil and heat up the whole evaporator coil, the defrost efficiency is higher, so it takes shorter defrost cycle.

Temperature fluctuates small. Because the hot gas defrost is more efficient than electric defrost, it takes short defrost cycle. The shorter defrost cycle, the smaller temperature fluctuates.

Low energy consumption. The hot gas defrost system has higher efficiency, short defrost cycle, so it consume less energy.

Glen Refrigeration-Hot Gas Defrost Refrigeration System Provider

Glen refrigeration also has the honor and distinction of being the leading company to deliver the newest, most innovative refrigeration technology in China, includes horizontal condensing unit for refrigerated display cabinets, outdoor condensing unit for commercial refrigeration and cold storage, water-cooled condensing unit for water loop systems, hot gas defrost outdoor condensing unit and evaporator, inverter condensing unit, R290 condensing unit, monoblock refrigeration unit. As such, Glen refrigeration is now considered the leading expert in the commercial refrigeration industry.

Sanyo Compressor Cold Room Condensing Unit

Panasonic Compressor Cold Room Condensing Unit

Copeland ZB Compressor Cold Room Condensing Unit

Copeland ZF Compressor Cold Room Condensing Unit

Copeland ZFI Compressor Cold Room Condensing Unit

Copeland ZSI Compressor Cold Room Condensing Unit

Top Mount Monoblock Refrigeration Unit

Side Mount Monoblock Refrigeration Unit

Bottom Mount Monoblock Refrigeration Unit

Ceiling Mount Monoblock Refrigeration Unit

Wall mounted Monoblock Refrigeration Unit

Let’s discuss how Glen Refrigeration can help you with complete commercial refrigeration system solutions! Feel free to contact us by email or Whatsapp or fill our the contact form below.

Email: info@greehvacr.com

Whatsapp: 0086 15057108995