What is Liquid Receiver?

The liquid receiver is also called liquid receiver tank. In refrigeration system, a liquid receiver is used to store refrigerant.

In condensing unit refrigeration system, when the refrigeration load changes, the thermal expansion valve or electronic expansion valve will adjust its opening degree accordingly, so the circulation volume of the refrigerant will be changed accordingly. At same times, in some cases, if the liquid supply in front of the expansion valve is insufficient, it will cause the expansion valve to work improperly, causing the instability in the operation of the entire refrigeration system. The function of receiver in refrigeration system is to ensure that there is sufficient liquid refrigerant supply in front of the expansion valve.

It is simply understand that the refrigerant receiver in the refrigeration system is like a water reservoir, which stores liquid refrigerant when the refrigeration load decreases and replenishes it when the load increases. This can avoid excessive liquid accumulation in the condenser, occupying too much heat exchange area and affecting condensation heat release, while ensuring that there is sufficient liquid supply in front of the expansion valve.

Therefore, as an additional “space” for the condenser, the refrigeration liquid receiver can effectively buffer and compensate for refrigeration load changes, thereby maintaining a stable liquid level in the condenser and sufficient liquid supply in front of the expansion valve, thereby ensuring the normal operation of the refrigeration system.

What’s the Liquid Receiver Location?

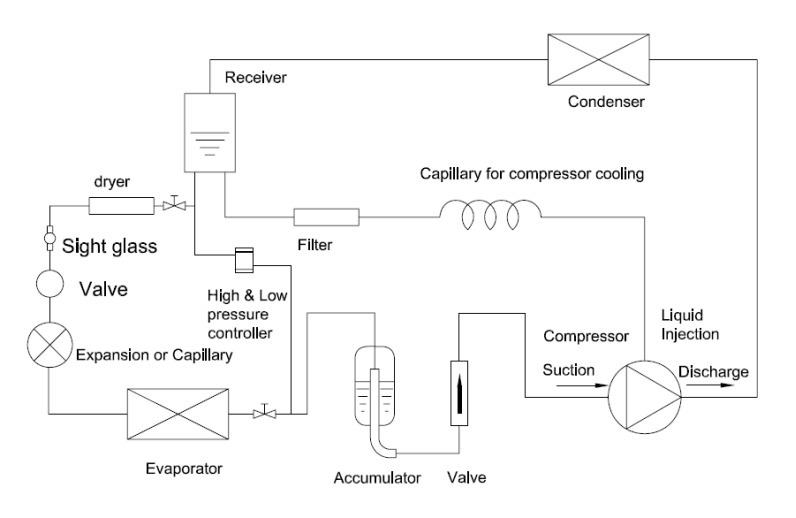

The refrigeration receiver tank is installed at the end of the high-pressure liquid pipe, located after the condenser and before the throttle valve, so it is also called high pressure accumulator.

But it is not accumulator what we often talked about. The “accumulator” we often talked about is installed before the compressor inlet to prevent liquid refrigerant from entering the compressor and causing liquid hammer. It is installed on the low pressure pipe, before the compressor inlet.

This is Glen Refrigeration’s Panasonic Compressor Outdoor Condensing Unit, it adopts Panasonic low temperature compressor, equipped with liquid injection. The cooling capacity is from 4 HP to 12.5 HP, the evaporating temperature is from -5℃ to -45℃, so it is both suitable for medium temperature refrigeration and low temperature refrigeration. For more details, please click here: Panasonic Compressor Outdoor Condensing Unit

Please see the Panasonic Compressor Outdoor Condensing Unit diagram below:

This is Glen Refrigeration’s Air Cooled Indoor Condensing Unit, adopts Sanyo CRSS compressor, with advantages of the low height and compact size, makes the refrigerated cabinet more effective volume. Glen Refrigeration offers 3/4 HP to 3 HP horizontal condensing unit for medium temperature refrigeration and low temperature refrigeration. Please click here if you are interested. Air Cooled Indoor Condensing Unit

Please see the Horizontal Condensing Unit with Liquid Receiver Tank and Accumulator diagram below:

This is Sanyo compressor outdoor condensing unit, it also adopts Sanyo CRSS compressor, different from the horizontal condensing unit, the outdoor condensing unit adopts vertical compressor. The cooling capacity is from -5℃ to -45℃, both for low temperature refrigeration and medium temperature refrigeration. If you are interested, please click here for more details: Sanyo Compressor Outdoor Condensing Unit

From the picture above, we can see clearly that the liquid receiver tank is installed at the end of the high-pressure liquid pipe, without thermal insulation cotton. While the accumulator is installed before the compressor inlet, it is with thermal insulation cotton.

How does a Liquid Receiver Work?

The refrigerant in the refrigeration system is compressed into a high-temperature, high-pressure gas by the compressor, this gas then flows into the condenser. In the condenser, heat is released to the external environment through heat exchange with air or cooling water, and the refrigerant temperature drops and condenses into liquid refrigerant. The liquid refrigerant then flows into the receiver.

The refrigeration receiver is like a station, the liquid refrigerant flows from condenser to the receiver tank. The liquid receiver purpose is to storage the refrigerant. When the refrigeration load changes, it can increase or decrease the supply of the refrigerant, ensuring that there is sufficient liquid supply in front of the Thermostatic Expansion Valves.

The working principle of the refrigerant receiver tank is based on the dynamic balance of pressure in the entire refrigeration system.

When the refrigeration system is working, the refrigerant flows under different states and pressures. When the refrigeration load decreases, it decrease the supply of the refrigerant to the expansion valve and the rest refrigerant is stored in the receiver tank. When the refrigeration load increased, it increase the supply of the refrigerant to the expansion valve.

What’s the Purpose of Receiver in Refrigeration System?

The refrigerant dissipates and condenses in the condenser, changes from gaseous state to liquid state, then enters into the liquid line receiver. The liquid receiver ensures that the refrigerant entering into the expansion valve is completely liquid and prevent liquid vapor from appearing due to poor condensation.

In refrigeration system, if there is no system receiver, that means there is no place to store the liquid refrigerant, the liquid refrigerant will accumulate at the bottom of condenser, thereby reducing the heat transfer area and affecting the condensation effect.

How Many Types of Receiver Tanks Are There?

The receiver tank is one of important refrigeration components in refrigeration system. The receiver tank in refrigeration system is used to storage liquid refrigerant, ensure the stable operation of the system. According to different classification standards, the liquid receiver in refrigeration system can be divided into:

- According to pressure

High pressure receiver: The high pressure receiver tank is a crucial component in a refrigeration system. Primarily used to store and balance the refrigerant pressure on the high-pressure side. The high-pressure receiver stores refrigerant and controls its pressure and flow rate, ensuring a stable and readily available refrigerant supply to meet the operational needs of refrigeration systems.

Here is the high pressure receiver of ourdoor condensing unt:

Low pressure receiver: Mainly used to store excess refrigerant liquid on the low-pressure side, they are typically installed in the compressor suction pipe to buffer the flow and prevent liquid refrigerant from entering the compressor. They focus on storage functions, providing additional volume to regulate the amount of refrigerant in the system. Generally they are used in large refrigeration system.

- According to structure

According to different structure, the receiver can be divided into vertical liquid receiver, horizontal liquid receiver.

Here is the vertical liquid receiver of Glen Refrigeration Horizontal Condensing Unit:

Here is the horizontal liquid receiver of Bitzer condensing unit:

What’s the Difference Between Liquid Receiver vs Accumulator?

- Different function

The liquid receiver is mainly used to store the liquid refrigerant. While the suction accumulator is mainly used to separate the vapor refrigerant from the liquid refrigerant. That means, the main function of receiver is to store; the main function of the refrigerant accumulator is to separate and store. So the structure of the refrigeration accumulator is more complex.

- Different Location

The liquid receiver acts as a stock of liquid refrigerant, located after the outlet of condenser in a compressor condensing unit; while the suction accumulator acts as a vapor-liquid separator and stock of liquid refrigerant, located after the outlet of evaporator in a refrigerant system.

- Different Structure

The composition of the liquid receiver is relatively simple. Except for the inlet and outlet pipes, it is empty inside.

While the structure of the suction accumulator is relative complex. When design a suction accumulator, it should consider from these three aspects:

The gas-liquid separator must have sufficient capacity to store excess liquid refrigerant. When the compressor shut down, the liquid accumulator is the coldest component in the system, so the refrigerant will migrate here, so it is necessary to ensure that the gas separator has sufficient capacity to store the liquid refrigerant.

Appropriate oil return holes and filters ensure that the refrigeration oil and gaseous refrigerant return to the compressor.

The size of the oil return holes is very important. The size of the oil return hole should try to ensure that no liquid refrigerant flows back to the compressor, but it should also ensure that the refrigeration oil can return to the compressor as much as possible.

The pressure loss of the liquid accumulator should be as small as possible.

Here is the inside structure of suction accumulator:

What’s the Difference Between Low Pressure Receiver vs Accumulator?

Maybe we will be confused between the Low-pressure liquid receivers and accumulators. In fact, they are two different items, but their usage function is somewhat similar, so in some cases they are considered the same device.

Low-pressure liquid receiver:

The low pressure receiver has the same functions as high pressure accumulator, is used to store excess refrigerant liquid on the low-pressure side. The main function is storage, providing additional volume to regulate the amount of refrigerant in the system. For small refrigeration systems, like our Panasonic compressor outdoor condensing unit, inverter condensing unit or water cooled condensing unit, there is no low pressure receiver. Generally they are used in large refrigeration system.

Accumulator:

The accumulator is used to separating liquid refrigerant from gas in a gas-liquid mixture, ensuring that only gaseous refrigerant enters the refrigeration compressor, preventing damage from liquid hammer. Typically installed before the compressor suction pipe.

Please see the Accumulator installed on the Copeland Outdoor Condensing Unit:

Please see the Accumulator installed on the Water Cooled Condensing Unit:

Low pressure receiver and Accumulator have similar functions, but differ in their design and application. In some small refrigeration systems, the accumulator may also function as a low-pressure liquid receiver, and therefore are sometimes collectively referred to as “low-pressure receiver.” However, in large or complex systems, the two components are typically separate components, each performing specific functions.

How to Size a Liquid Receiver?

The refrigerant receiver capacity calculation can be according to the refrigerant charge of the refrigeration system. Firstly, calculate the refrigerant charge required for the refrigeration system at the maximum load, and then calculate the refrigerant charge required for the refrigeration system at minimum load. The difference between the two is the amount of the refrigerant that our liquid receiver needs to store. Generally, the accumulator cannot be fully filled. The maximum storage capacity is recommended not to exceed 80% of the volume. Then select the refrigerant receiver tank sizing according to the liquid receiver catalog.

How to Select a Liquid Receiver?

- Calculate the amount of the refrigerant charge of the refrigeration system.

First, calculate the total refrigerant demand of the refrigeration system during operation. Consider the refrigeration circulation volume during normal operation and the additional refrigerant demand during startup and shutdown. Consider the refrigeration system’s refrigerant flow rate and total system capacity, we can estimate the total refrigerant required and determine the refrigeration receiver capacity.

- Consider the refrigeration system’s specific operation requirements.

Refrigeration systems may need to operate under varying operating conditions, such as high ambient temperature, high humidity, or frequent starts and stops. These specific requirements can affect refrigerant consumption and the receiver tank’s refill capacity. These specific factors must be considered when sizing the receiver tank to ensure it can meet the system’s requirements under various operating conditions.

- Safety and Efficiency Verification

After determining the size of the liquid receiver, a safety and efficiency verification is required. This includes checking whether the receiver’s design complies with relevant safety standards and whether it can meet the refrigerant requirements for efficient system operation. Furthermore, the receiver’s placement and ease of maintenance must be considered to ensure safety and reliability in actual use.

If the liquid receiver tank is too small, the condensed liquid refrigerant will accumulate in large quantities in the condenser, thereby reducing the condensation area, causing the condensation pressure to rise and the discharge temperature to rise, thus disrupting the normal operation of the refrigeration system. When the refrigeration system stops running, the solenoid valve is closed, that is, the outlet of the liquid receiver tank is closed. When the outside temperature rises, the volume of the liquid refrigerant in the receiver tank will expand, generating huge pressure. That’s why the liquid level of the high-pressure receiver shall not exceed 80% of its volume.

Who are Refrigerant Liquid Receiver Manufacturer In China?

Although we are not refrigerant liquid receiver manufacturer, but we will suggest high quality refrigerant liquid receiver manufacturer in China to you if you need. Because all of our condensing units use the receiver, including indoor condensing unit, outdoor condensing unit, inverter condensing unit, water cooled condensing unit, multi-compressor refrigeration system and so on. Good quality spare parts is the basement of a good condensing unit.

Established in 2014, Glen Refrigeration is the leading manufacturer and supplier of indoor condensing unit and outdoor condensing unit for commercial refrigeration and cold storage,working in close cooperation with many leading commercial refrigeration equipment manufacturers.

In addition to offering standard products including Indoor Condensing Unit, Outdoor Condensing Unit, Air Cooled Condensing Unit, Water-cooled Condensing unit, Inverter condensing unit, Parallel-compressor outdoor condensing unit, Air cooler evaporator, Monoblock refrigeration unit for commercial refrigeration and cold storage. Glen Refrigeration also offers custom refrigeration system for most customer’s specific applications.

Let’s discuss a project and offer a custom refrigeration solutions for you!

Glen Refrigeration’s main goal is to meet our customer’s demands for refrigeration and freezing equipment with high reliability and high efficiency, and minimum service and maintenance costs. After years of experience, we know what our customers need, and we are more than qualified to provide the best service imaginable, and guarantee our customers satisfaction.

Interested in Learning More?

Glen Refrigeration can help with Commercial Refrigeration System Solutions.