The condenser is one of the main heat exchanger in refrigeration system. The function of condenser in refrigeration system is to cool and condense the high-temperature high-pressure refrigerant vapor discharged from the compressor into medium-temperature high-pressure refrigerant.

What Are Different Types of Condenser?

According to cooling types, it can be divided into water cooled condenser, air cooled condenser and evaporative condenser.

Water-cooled condenser is one of types of condenser in refrigeration system. It mainly used in water cooled condensing unit. In water loop refrigeration, the refrigeration compressor discharge the high-temperature and high-pressure vapor refrigerant to the water cooled condenser, the water in the water-cooled condenser takes away the condensation heat, and the high-temperature high-pressure vapor refrigerant turns into medium-temperature high-pressure refrigerant.

Water-cooled condensers can be divided into three types: brazed plate heat exchanger, shell-and-tube condensers and jacket-and-tube condensers according to their structural forms. Please see below:

Glen Refrigeration brazed plate heat exchanger water cooled condensing unit and shell-tube condenser water cooled condensing unit.

Air cooled condensers are widely used in commercial refrigeration, transport refrigeration and industry refrigeration. It is one of 4 main components of a refrigeration system. Air cooled surface condenser is commonly found in refrigerator condensing unit, indoor condensing unit, remote air cooled condenser unit, cold room condensing unit, horizontal condensing unit, walk in cooler condensing unit, monoblock refrigeration unit, and etc.

The air cooled condenser function is to take away the condensation heat, dissipate heat into the air by the fan motor, turn the high-temperature high-pressure vapor refrigerant into medium-temperature high-pressure refrigerant.

According to different air flow modes, it can be divided into two types: forced air cooled condenser and natural air cooled condenser.

The evaporative condenser is also called air cooled steam condenser. The work principle is similar as cooling tower. It is mainly composed of three parts: a heat exchanger, a water circulation system, and a fan system.

What is Air-cooled Condenser?

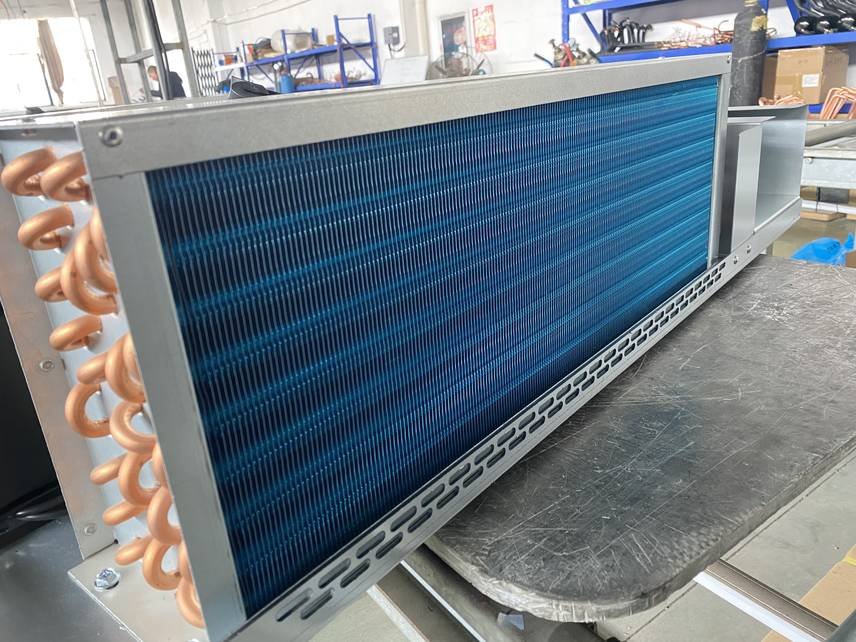

The air-cooled condenser is a kind of heat exchanger for refrigeration system. It widely used in commercial refrigeration condensing unit. It is composed of aluminum foils, copper tubes and sheet metal. The function of aluminum foils is to increase heat dissipation area and dissipate heat faster. The aluminum foils and the cooper tube are integrated by the a expansion machine.

How Does An Air Cooled Condenser Work?

The condenser inlet is connected with compressor discharge pipe. The high-temperature high-pressure vapor refrigerant discharged from the compressor, then enters into the air cooled condenser. The air takes away the heat from the refrigerant through the aluminum foils and fan motor. Then the high-temperature high-pressure refrigerant turns into medium-temperature high-pressure refrigerant. The outlet of the condenser is connected to filter dryer.

What’s The Difference Between Air Cooled and Water Cooled Condenser?

The main difference between air cooled and water cooled condenser is different cooling medium in heat treatment.

The air-cooled condenser use air as cooling medium in refrigeration, while water-cooled condenser use water as cooling medium in refrigeration. Because of different cooling medium, the condensers are different.

Air cooling condenser system uses finned tube heat exchanger, while water-cooled condensing units use brazed plate heat exchanger or shell and tube water-cooled condensers.

What’s the Advantages and Disadvantages of Air Cooled Condenser ?

Air-cooled refrigerant condensers mainly have the following advantages:

- Air condenser cooling system use air as cooling medium, no need water, saves water resources.

- Air cooled condenser system no need to established a water circulating system, so the investment and operation costs are relatively low.

- Without limited by water resources, the refrigeration air cooled condenser has stronger adaptability, easy to install and maintenance.

- Without water circulating system, the air cooler cooling system avoids the corrosion problem of water condensation.

- The refrigeration air cooled condenser design can be customized according to difference cooling capacities. If you have the air cooled condenser diagram, we can produce according to your requirements.

The disadvantages of air cooled condenser unit:

- The heat dissipation of air cooled condenser unit is not as good as water water cooled condenser unit.

- The condensing temperature of air cooled condenser unit is greatly affected by the ambient temperature. In summer or poor ventilation areas, the condensing temperature is relatively high, so the refrigeration performance will be affected. So the selection of the right location for an outdoor condensing unit is extremely important.

How to Improve the Air Cooled Condenser Unit Performance?

The air cooled condenser coil plays a important role in 4 parts of refrigeration system. The air cooled condenser performance is not only relevant to the performance of the entire refrigeration system, but also reduce the condensing unit failure rate. So the air cooled condenser sizing and air cooled condenser fans are key points when design.

Here are four points to improve the air cooled condenser performance:

- Use inner grooved copper tube to improve the performance

The air cooled condenser unit is made of aluminum foils and cooper tubes. Generally the cooper tubes are divided into inner grooved copper tube and smooth cooper tubes. Compared with smooth cooper tubes, the inner grooved copper tube increases the inner surface area, fasten the heat exchange, thus improves the air cooled condenser performance.

We believe that good products comes from good material. The inner grooved copper tube we used is Hailiang brand, which is one of the world’s largest producers for cooper tubes.

- Use Hydrophilic aluminum foil to improve the performance

The refrigeration compressor discharges high-temperature high-pressure refrigerant to the condenser. The purpose of condenser in refrigeration system is to dissipate the heat. During this process, the aluminum foils plays the role of increasing the heat dissipation area and enhancing the heat dissipation effect.

The hydrophilic aluminum foil is treated with a special process and coated coated with a hydrophilic layer on its surface. This special process makes the blue aluminum foil has many advantages compared with normal aluminum foil.

(1) Increase the anti-corrosion function.

(2) Easy for condenser water to spread and flow down, thus increasing the heat exchange rate by 5%;

- Clean air cooled condenser to improve the performance

The air cooled condensing unit generally installed outside of building, after long-time use, it will be dusty. More seriously, it will be dirty and clogged. If it is not cleaned in time, it will not only affect performance of the unit, but also the normal operation of the condensing unit.

So it is very important to clean the air cooled condenser unit in every two or three month. In every condensing units, we will put a label to remind our customer to clean condenser in time.

- Install a oil separator before the condenser to improve the performance

In the refrigeration system, the lubricating oil of the compressor will be discharged with the high-pressure refrigerant after atomization. In order to prevent lubricating oil from entering the condenser, an oil separator is installed in front of the condenser to separate most of the oil in the system and prevent a thick oil film from forming in the condenser, which affects the heat exchange efficiency of the condenser.

If you have any questions about the our products, we are here to help!

Contact us by email or fill out the contact form below.

Email: info@greehvacr.com

Whatsapp: 0086 15057108995

We look forward to your inquiry!