There are two kinds of hot gas defrosting methods. One is hot gas bypass refrigeration, the other is reverse cycle defrost.

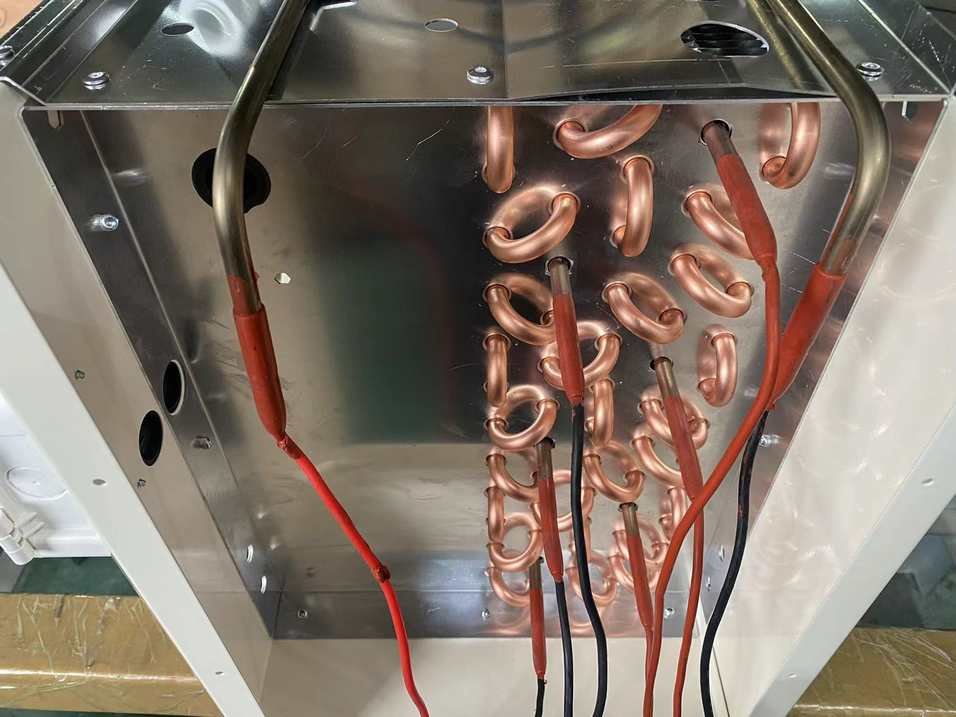

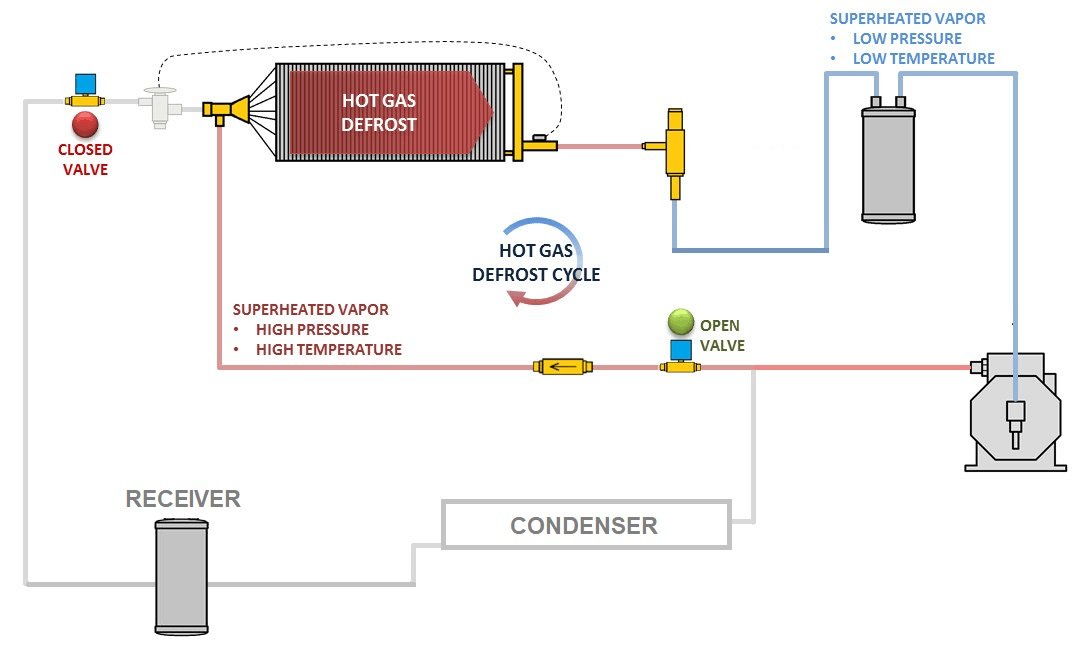

In hot gas bypass defrost, the compressed high pressure and high temperature vapor refrigerant from the refrigeration compressor as the heat source, is directed through the walk in freezer evaporator coil by a bypass pipe, warming it and melt the frost and ice. To make hot gas defrosting method working, a hot gas defrost piping and hot gas defrost valve (solenoid valve) are added to the compressor discharge line to create a shortcut between the compressor discharge and evaporator inlet.

While the reverse cycle hot gas defrost uses the four-way valve, change the refrigerant flow direction in refrigeration cycle, that means in reverse cycle defrost, the condenser acts as evaporator, while the evaporator acts as condenser. The high-temperature high-pressure gas refrigerant discharged from the compressor, through a four-way valve, enter into the evaporator walk in cooler to melt the ice.

To make hot gas defrosting method working, a hot gas defrost piping and hot gas defrost valve (solenoid valve) are added to the compressor discharge line to create a shortcut between the compressor discharge and evaporator inlet.