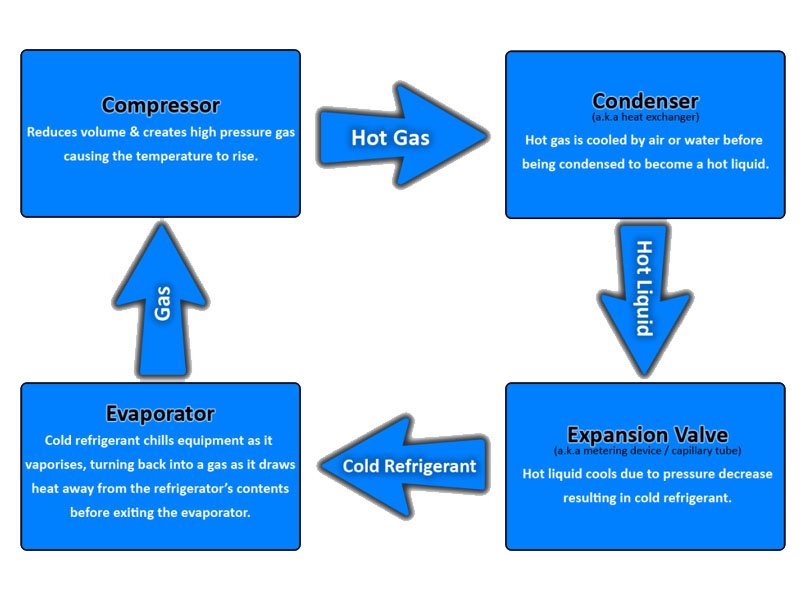

What is vapour compression refrigeration system?

Vapor absorption compression refrigeration belongs to phase change refrigeration, which obtain the cooling capacity from the refrigerant state change. It is composed of refrigeration compressor, condenser, expansion valve or capillary, evaporator and other refrigeration parts. They are connected by pipes, forming a closed refrigeration system.

Vapour Compression Refrigeration System Diagram

Vapour Compression Refrigeration System Components

Refrigeration Compressor

Refrigeration Compressor is the most important component of the vapor absorption compression refrigeration system. The function of the compressor is to inhale low-temperature refrigerant from the evaporator side, compress it into high-pressure and high-temperature refrigerant vapor, and send it to the condenser.

Glen Refrigeration supplies Sanyo rotary refrigeration compressor for commercial refrigeration and transport refrigeration. It is earliest developed rotary compressor for commercial refrigeration and famous for its high reliability.

Features:

- High reliability; Sanyo rotary refrigeration compressor is developed with high reliability.

- Wide evaporating temperature; The evaporating temperature is from 0°C to -45 °C.

- Low height and compact size; The horizontal rotary compressor has the advantages of low height, which can make the condensing unit more compact.

- Eco-friendly; R290 fixed speed refrigeration compressors and R290 variable speed refrigeration compressors are all available.

- Inverter technology; We have R410A, R404A, R290 variable speed refrigeration compressor with inverter technology for your selection.

Please click here if any interested in the Sanyo Rotary Refrigeration Compressor.

Condenser

Condenser is also called heat exchanger. The role of condenser in the refrigeration system is to change the high-pressure and high-temperature refrigerant vapor to high-pressure and low-temperature liquid refrigerant by the fin and fan motor or water take away the heat. According to different heat exchange, there is air-cooled condenser, water-cooled condenser and evaporative condenser.

According to different condensers, Glen Refrigeration has air cooled condensing unit and water-cooled condensing unit.

The air cooled condensing unit uses finned type copper tube heat exchanger and EBM motor to take away the heat.

The water-cooled condensing unit adopts plate heat exchanger to take away the heat by water-water.

Please click here if any interested in Air Cooled Condensing Unit and Water-cooled Condensing Unit.

Evaporator

Like the condenser, the evaporator also belongs to heat exchanger. The evaporator absorbs the heat and makes the low-pressure and low-temperature liquid refrigerant change to low-pressure and low-temperature gaseous state to achieve the cooling effect. In addition, the evaporator also absorbs water from the air.

Glen Refrigeration supplies the unit cooler evaporator for the cold room, freezer room, and walk in cooler, walk in freezer.

Solenoid Valve

Solenoid valve is an electrically controlled automatic opening of the globe valve. It is usually installed in the refrigeration system, for automatic switching on and off the refrigeration system. Solenoid valve is usually installed between the expansion valve and the condenser. The position should be as close as to the expansion valve, because the expansion valve is only a throttling element, so it needs to use the solenoid valve to cut off the liquid pipeline.

Expansion Valve

The throttling element has evaporation valve and capillary. The capillary widely used in small refrigeration system; while expansion valve can use in both small and large refrigeration system. The function of the expansion valve is to regulate the refrigerant flow. It is not only control the refrigerant flow to the evaporator, but also the throttle valve of the whole refrigeration system. The thermal expansion valve uses the change of refrigerant superheat at the evaporator outlet to adjust the liquid supply, which is connected to the liquid inlet pipe of the evaporator; while the temperature wrap is arranged on the outlet (air outlet) pipe of the evaporator. Usually, according to the structure of the thermal expansion valve, it is divided into:

(1) Internal balance thermal expansion valve;

(2) External balance thermal expansion valve.

Internal balance thermal expansion valve is generally used in small evaporator.

External balance thermal expansion valve: The external balance thermal expansion valve is for long pipelines or large resistance evaporator. The internal balance expansion valve can be used in the evaporator for high temperature cold room, while external balance expansion valve may be used for low temperature cold room.

Oil Separator

Usually, the oil separator is installed between the refrigeration compressor and the condenser to separate the refrigerant oil carried in the refrigerant vapor. Then use the oil return device, returns the oil back to the compressor.

Accumulator

The main function of the accumulator is to separate the gaseous refrigerant from the liquid refrigerant, which preventing the liquid strike; at same time, storage the liquid refrigerant, adjust the liquid refrigerant supply according to the load.

Receiver

The function of the receiver is to balance the refrigerant circulation in the system, making the refrigeration system operate normally. It is generally installed between the condenser and expansion valve. In order to make the liquid refrigerant come into the receiver, the place of receiver should be lower than condenser.

Filter Dryer

In order to ensure the normal circulation of refrigerant, the refrigeration system must be kept clean and dry. The filter dryer is usually installed in front of the throttle element. When the liquid refrigerant passes through the filter dryer, it can effectively prevent clogging in the throttle element.

Sight-Glass

It is mainly used to indicate the refrigerant condition in the liquid pipeline of refrigeration system and the water content in the refrigerant.

High and Low Pressure Controller (Relay)

The high and low pressure Relay is to prevent the pressure of the refrigeration system over-high and over-low. The high pressure relay will protect when the discharge pressure is over-high, and the compressor stops working. After finding the reason and eliminating the problem of over-high pressure, the compressor can be restarted.

The low pressure relay will protect when the suction pressure drops to the setting limit, it will automatically protect and stop the compressor. When the suction pressure rises to the setting limit, the compressor will be restarted.

Glen Refrigeration-Leading COMMERCIAL REFRIGERATION SYSTEM Manufacturer

Glen Refrigeration specialize in Condensing Units and Monoblock Refrigeration Units for commercial refrigeration applications. Whether you need basic condensing unit, or a custom refrigeration solution, Glen Refrigeration will be able to cater to your business’ requirements. Our expertise and adaptability is what sets us apart from the crowd, give us a call to talk about the custom refrigeration system needs of your commercial refrigeration equipment.

Are You Interested In a CONDENSING UNIT For Your Commercial Refrigeration Equipment?

Whatever you need, we’re here to help!

Feel free to contact with us by email or Whatsapp or fill out the contatc form below.

Email: info@greehvacr.com

Whatsapp: 0086 15057108995