What is Suction Accumulator?

The suction line accumulator is a vapor-liquid separator. In suction accumulator refrigeration system, it is mainly used to separate the vapor refrigerant and the liquid refrigerant to avoid the liquid refrigerant entering into the compressor and causing the compressor liquid hammer. It is installed in the low-pressure side, between the outlet of the evaporator and the compressor.

As we all know, that there are four main components in the refrigeration system–Refrigeration compressor, condenser, expansion valve and evaporator. In addition, there are also some very important auxiliary components, like oil separator , receiver, suction accumulators and so on. Today, we are going to talk about the suction line accumulators and the function of accumulator in refrigeration.

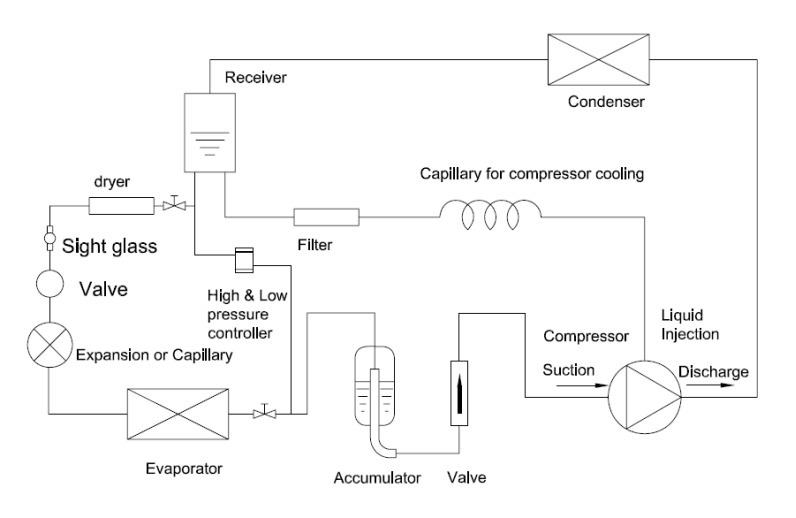

This is Air Cooled Indoor Condensing Unit from 0.75HP to 3HP, adopts Sanyo rotary refrigeration compressor, with low height and compact size, the evaporating temperature is from -5℃ to -45℃, so it is suitable for medium temperature refrigeration and also low temperature refrigeration. If you need more information, please contact with us.

Please see the Air Cooled Indoor Condensing Unit with accumulator in refrigeration cycle diagram below:

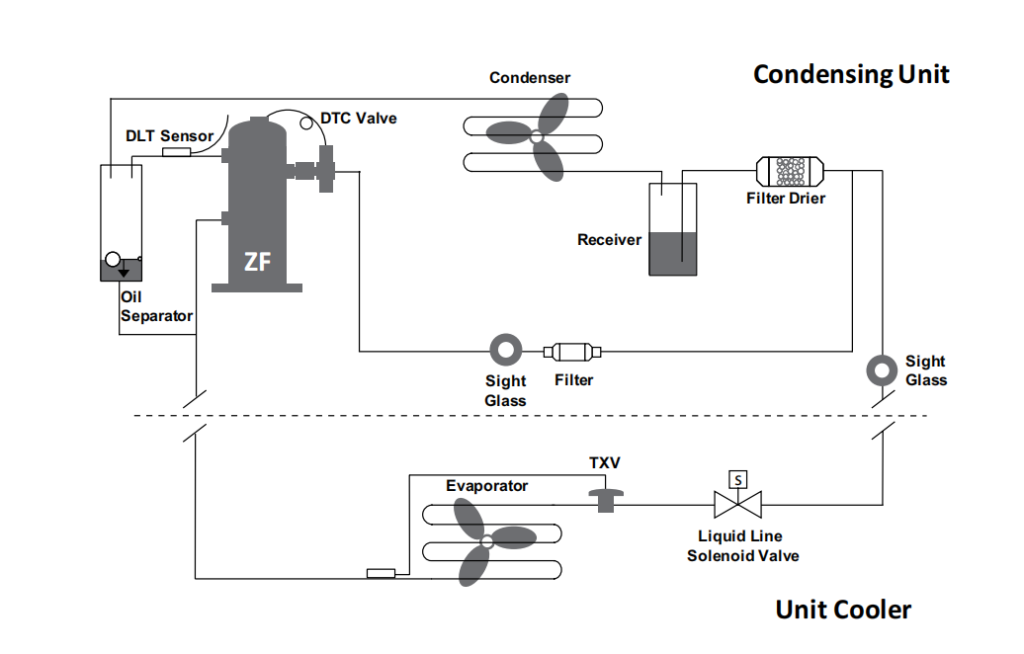

This is Panasonic Compressor Outdoor Condensing Unit from 4HP to 12.5HP, adopts Panasonic scroll compressor, with high reliability and low noise, the evaporating temperature is from -5℃ to -45℃, so it is suitable for medium temperature refrigeration and also low temperature refrigeration. If you need more information, please contact with us.

The Accumulator in the picture above is a Heat Exchange Accumulator with Receiver.

Please see the Panasonic compressor outdoor condensing unit refrigeration system diagram below:

Where is The Suction Accumulator Located?

The refrigeration accumulator is located on the suction pipe, between the evaporator outlet and compressor. Suction Accumulators are containers for separate the vapor refrigerant and the liquid refrigerant to avoid the liquid refrigerant entering into the compressor and causing the compressor liquid hammer.

Maybe some customers confuse the receiver and accumulator and confuse the suction line accumulator location and receiver location. In fact, the suction accumulator location is quite different from the receiver location.

Suction accumulator: Between the evaporator outlet and refrigeration compressor suction pipe.

Liquid receiver: After the condenser outlet

This is Copeland Compressor Outdoor Condensing Unit, features ZF Copeland scroll compressor, designed for medium temperature refrigeration and low temperature refrigeration. The cooling capacity is from 3HP to 18HP. Please click here for more details: Copeland ZF compressor outdoor condensing unit

Here is the accumulator in ZF compressor Copeland outdoor condensing unit refrigeration system diagram below:

What’s the Suction Accumulator Function?

The function of the suction accumulator is to separate the vapor refrigerant from the liquid refrigerant, store the liquid refrigerant in the accumulator, ensure the refrigerant entering into the compressor is completely gaseous and protect the compressor from liquid hammer.

The vapor refrigerant evaporates in the evaporator, changes from the liquid state to gaseous state, then entering into the accumulator in refrigeration system, but sometimes, some liquid refrigerant can’t evaporate completely in the evaporator, the suction accumulator purpose is separate the vapor refrigerant from the liquid refrigerant.

The function of accumulator is very import for the refrigeration compressor and the refrigeration system. The suction line accumulator purpose is to ensure that the refrigerant entering the compressor is in gaseous state. Because the liquid refrigerant entering the compressor can damage its internal structure. When moving parts such as the rotor and blades rotate at high speed, liquid ingress can collide with them, causing damage or increased wear. Furthermore, liquid refrigerant can cause liquid hammer inside the compressor, seriously impacting the compressor’s sealing performance and stability.

Secondly, the liquid refrigerant entering the compressor can affect refrigeration efficiency. When the refrigerant is compressed within the compressor, if it contains liquid, it can cause an abnormal increase in internal pressure, affecting refrigerant circulation and cooling efficiency. Furthermore, liquid in the compressor can create bubbles, which occupy space and reduce refrigerant compression efficiency.

Therefore, the refrigeration accumulator function is very important in refrigeration systems, it is essential that the refrigerant enters the compressor in a gaseous state. Typically, before entering the compressor, the refrigerant passes through components such as the evaporator, where the liquid refrigerant evaporates into a gaseous state before entering the compressor for compression. This ensures proper functioning of the compressor and the achievement of cooling efficiency.

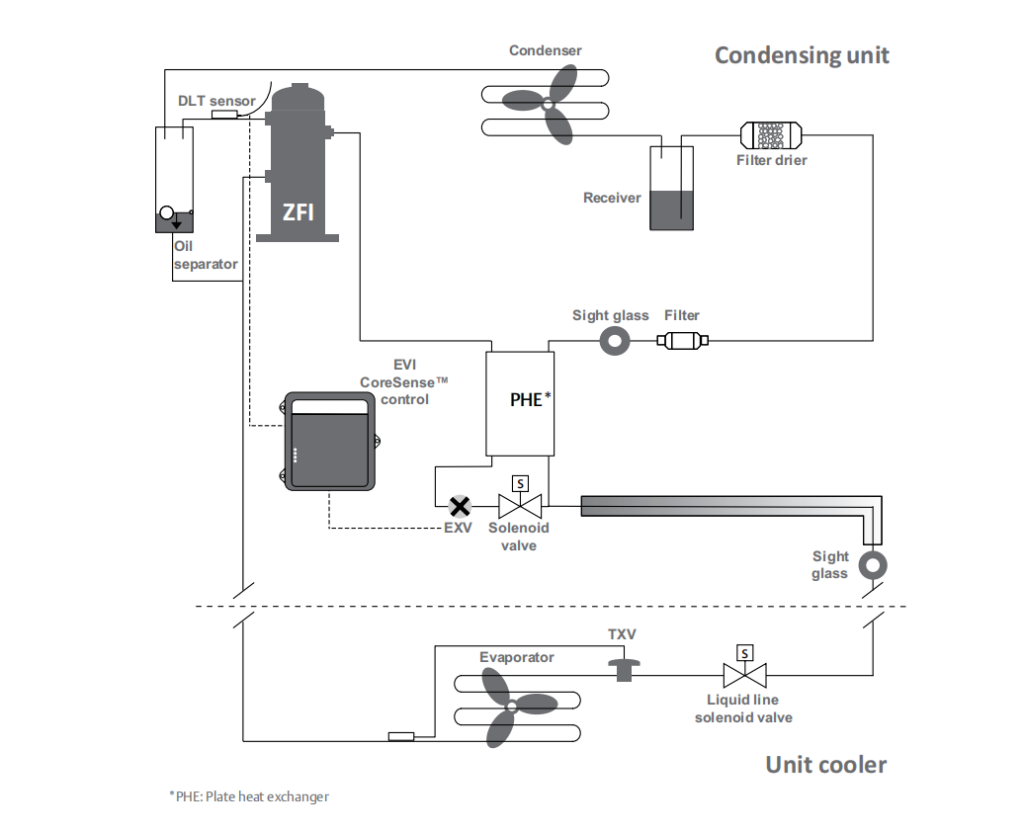

This is Glen Refrigeration’s ZFI compressor Copeland Condensing unit, ZFI Copeland compressor is designed with vapor injection, increases the condensing unit’s cooling capacity in low evaporating temperature. Glen Refrigeration offers ZFI compressor Copeland Condensing unit from 4 HP to 30 HP. If you need more information, please click here: Copeland ZFI compressor outdoor condensing unit

Here is the accumulator in ZFI compressor Copeland outdoor condensing unit refrigeration system wire diagram:

What’s the Suction Line Accumulator Diagram?

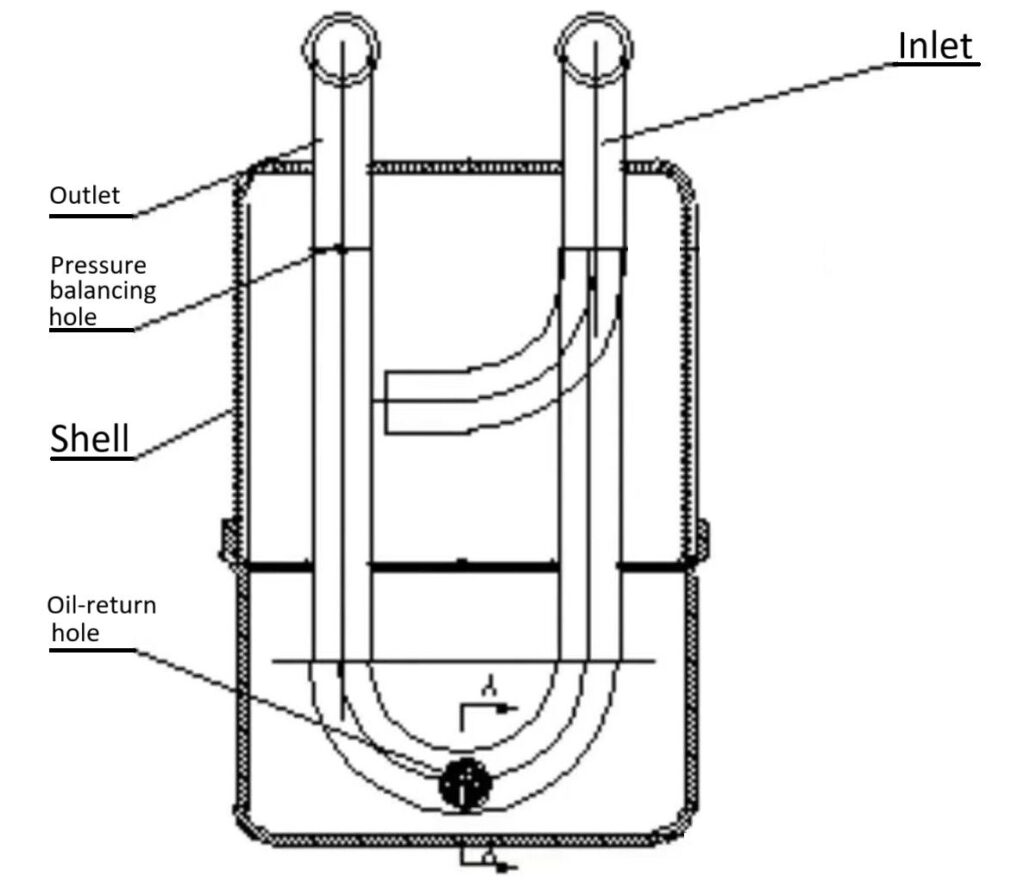

The refrigerant suction line accumulator primarily consists of a housing, an inlet pipe, an outlet pipe and an oil return hole & filter. Please see the suction line accumulator diagram below:

From the suction accumulator diagram above, we can see that when the gas-liquid mixture refrigerant enters the gas-liquid separator from the inlet pipe, it circulates inside of the suction accumulator. The liquid refrigerant will be settle to the bottom of the accumulator because of the centrifugal force. The gaseous refrigerant, due to its lower density, flows upward and out through the outlet pipe and into the compressor.

At the bottom of the outlet pipe, there is a suction accumulator oil return hole, the oil is returned back to the compressor from this hole. The oil hole is very important for the suction accumulator design.

The oil return hole at the bottom of the gas-liquid separator is carefully designed to ensure that the refrigerant oil can smoothly return to the compressor. Refrigerant oil plays a vital role in the refrigeration system, including lubricating the compressor’s moving parts, reducing wear and sealing. Excessive liquid refrigerant dilutes the refrigerant oil, reducing its lubricating properties and, in severe cases, even damaging the compressor. Furthermore, a filter is installed on the oil return hole to intercept various impurities in the system.

Generally the refrigeration system has high temperature refrigeration condition, medium temperature refrigeration condition and low temperature refrigeration condition. Under low temperature conditions, there will be liquid refrigerant at the outlet of the evaporator. Therefore, the refrigerant accumulator function is to separate the gaseous and liquid refrigerant. The liquid refrigerant is stored in the separator to prevent it from entering the compressor and causing liquid hammer.

How Does a Suction Line Accumulator Work?

The work principle of the suction accumulator in refrigeration system is to use the effect of gravity, the heavier liquid refrigerant sinks to the bottom, and the lighter gaseous refrigerant rises to the top and is discharged to the compressor. The purpose of accumulator in refrigeration system is to separate the liquid refrigerant and gases refrigerant by using the difference in their physical properties.

When the the gas-liquid mixture refrigerant enters the suction accumulator, its flow rate decreases due to the sudden expansion of the passageway. At this point, some of the liquid refrigerant evaporates into gas refrigerant due to the drop in pressure. This phase change refrigeration absorbs a large amount of heat, significantly reducing the temperature of the remaining liquid refrigerant, while the gas refrigerant and liquid refrigerant are separated due to the density difference.

What’s the Different Between Liquid Receiver vs Accumulator?

- Different function

The function of accumulator in refrigeration system is mainly used to separate the vapor refrigerant from the liquid refrigerant. While the purpose of the liquid receiver is mainly used to store the liquid refrigerant. That means, the mainly function of receiver is to store; the main function of the refrigerant accumulator is to separate and store. So the structure of the refrigeration accumulator is more complex.

Here is the R404A Indoor Condensing Unit. The liquid receiver is located in the liquid line. The accumulator is located in the suction line, that’s why it is called suction line accumulator. Glen Refrigeration offers R404A indoor condensing unit for medium temperature refrigeration and low temperature refrigeration from 3/4HP to 3HP, if you are interested, click here for more details: R404A Indoor Condensing Unit

- Different Structure

The structure of the accumulator for refrigeration system is much more complex than the liquid receiver. Firstly, the gas-liquid separator must have sufficient capacity to store excess liquid refrigerant. When the compressor shut down, the liquid accumulator is the coldest component in the system, so the refrigerant will migrate here, so it is necessary to ensure that the gas separator has sufficient capacity to store the liquid refrigerant. Secondly, there is a oil return hole at the bottom of the outlet pipe. The function of the oil return hole and filter ensures that the refrigeration oil and gaseous refrigerant return to the compressor.

While the composition of the liquid receiver is relatively simple. Except for the inlet and outlet pipes, it is empty inside.

What are Types of Suction Accumulator?

There are several different types of accumulator in refrigeration system, like suction line accumulator, heat exchange accumulator, heat exchange accumulator with receiver, vertical accumulator, horizontal accumulator and compressor accumulator. These are the main accumulator types.

- Suction Line Accumulator

The suction line accumulator widely used in refrigeration system and heat pump system. It is a vapor-liquid separator, consists of a housing, an inlet pipe, an outlet pipe and an oil return hole & filter.

- Heat Exchanger Accumulator

As the name implies, the heat exchanger accumulator combines the function of the vapor-liquid separator accumulator and heat exchange. Please see the pictures below:

From the picture above, there are four connections on the accumulator. The function of this kind suction accumulator is to make the suction accumulator heat exchange with the liquid pipe, use the heat of the liquid pipe to make the refrigerant vapor in the gas-liquid separator to achieve reasonably superheat, avoiding liquid shock in the compressor.

We all know that the refrigeration system can be divided into high-pressure side and low-pressure side. The high-pressure refrigerant, with its high temperature, requires to cool it. While the-low pressure refrigerant passing through the evaporator requires a gas-liquid separator to separate the gaseous and liquid refrigerant, this ensures that only gaseous refrigerant can enter the compressor, avoiding liquid compression and extending the compressor’s life. But this kind of heat exchanger accumulator seldom used in our outdoor condensing unit.

- Heat Exchanger Accumulator with Liquid Receiver

The heat exchanger accumulator with liquid receiver has same principle as the heat exchanger accumulator, and it is the upgrade version of the heat exchanger accumulator.

It consists of a gas-liquid separator and a receiver. The gas-liquid separator is installed inside of the receiver. From the appearance, it is as similar as the suction line accumulator or heat exchanger accumulator. Here is the heat exchange accumulator with liquid receiver diagram:

From the gas-liquid separator with liquid receiver diagram, we can see that there are four connections. Because the liquid refrigerant inside of the receiver that needs to be cooled, while the low-pressure low-temperature refrigerant inside of the accumulator needs to be heated. This heat exchange accumulator with liquid receiver create a heat exchange environment, which greatly improves system efficiency and achieves better cooling results.

This heat exchange accumulator with liquid receiver widely used in Glen Refrigeration’s outdoor condensing unit.

This is Glen Refrigeration Panasonic compressor outdoor condensing unit, adopts heat exchange accumulator with liquid receiver.

How to Select a Suction Line Accumulator?

The selection of a suction line accumulator is also very important. There are several key factors to consider when selecting the right accumulator:

- Refrigerant Type

Different refrigerants may require different types of accumulators. For example, the Freon and CO2. The Freon refrigerant is easy to liquefy; while the CO2 is difficult to liquefy. The refrigeration accumulators of Freon and CO2 are different.

- Accumulator volume

The accumulator must be able to handle the refrigeration system’s maximum flow rate. If the separator is too small, it may not effectively separate the refrigerant; if it is too large, it may increase the system’s size and cost.

- Operating Pressure and Temperature

The accumulator must be designed to withstand the system’s operating pressure and temperature. Systems operating at high temperatures or high pressures may require a more robust separator.

- Separation Efficiency

The accumulator’s efficiency determines how much liquid refrigerant it can separate. A high-quality high-efficiency separator can reduce the risk of compressor liquid hammer but may also be more expensive.

- Installation Space

The size and shape of the accumulator must fit the installation space. Limited space may require a more compact separator.

Glen Refrigeration is the leading condensing unit and monoblock refrigeration unit manufacturer in China, although we are not suction accumulator manufacturer in China, but we would like to support you to find the good quality accumulator manufacturers. Because almost all of our condensing units use the suction accumulator.

Glen Refrigeration’s main goal is to meet our customer’s demands for refrigeration and freezing equipment with high reliability and high efficiency, and minimum service and maintenance costs. After years of experience, we know what our customers need, and we are more than qualified to provide the best service imaginable, and guarantee our customers satisfaction.

Interested in Learning More?

Glen Refrigeration can help with Commercial Refrigeration System Solutions.