About Oil Separator Refrigeration System, we would like to share some views and experiences about the use. As far as we know, the compressor oil is very important for a refrigeration compressor and the refrigeration system. It can reduce internal friction and wear of the compressor and maintain good operating efficiency.

Good oil return is crucial for the long-term and stable operation of a refrigeration system. If the refrigeration system does not have an effective oil return, the lubricating oil may accumulate in the evaporator or other components. This will not only reduce the heat exchange efficiency,but also increase the load on the compressor, and may even cause the compressor to fail prematurely due to lack of lubrication oil.

Because oil return is so important for the refrigeration system, many customers will require to install a oil separator in outdoor condensing unit. Or ask “Can we add an oil separator in your outdoor condensing unit?”

So when are oil separators required? What type of refrigeration system requires an oil separator? We would like to share some views and experiences about the use of refrigeration oil separators.

Glen Refrigeration is a leading condensing unit and monoblock refrigeration unit manufacturer in China. We professionally manufacture horizontal condensing unit, outdoor condensing unit, inverter condensing unit, air cooled condensing unit, water cooled condensing unit, hot gas defrosting refrigeration systems, multi-compressor refrigeration system, monoblock refrigeration unit, cold room evaporator and so on.

For outdoor condensing units, we have different series:

- Sanyo compressor outdoor condensing unit

- Panasonic scroll compressor outdoor condensing unit

- Emerson scroll compressor ZB series outdoor condensing unit

- Emerson scroll compressor ZF series outdoor condensing unit

- Emerson scroll compressor ZFI series outdoor condensing unit

- Emerson scroll compressor ZSI series outdoor condensing unit

Now let’s analyze each of them one by one:

Sanyo Compressor Outdoor Condensing Unit

The outdoor condensing units adopts Sanyo rotary refrigeration compressor, with cooling capacity 1 HP, 1.5 HP, 2.5 HP and 3 HP. Sanyo compressor is a rotary vane compressor, equipped with liquid injection, designed for medium temperature refrigeration and also low temperature refrigeration.

- Refrigerant: R404A, R448A, R449A, R455A

- Power supply: 220V/50Hz, 1PH or 380V/50Hz, 3PH or 220V/60Hz, 3PH

- Cooling capacity: 1 HP to 3 HP

- Evaporating temp.: -5°C to -45°C

For Sanyo rotary refrigeration compressor outdoor condensing unit, it don’t need to install the oil separator.

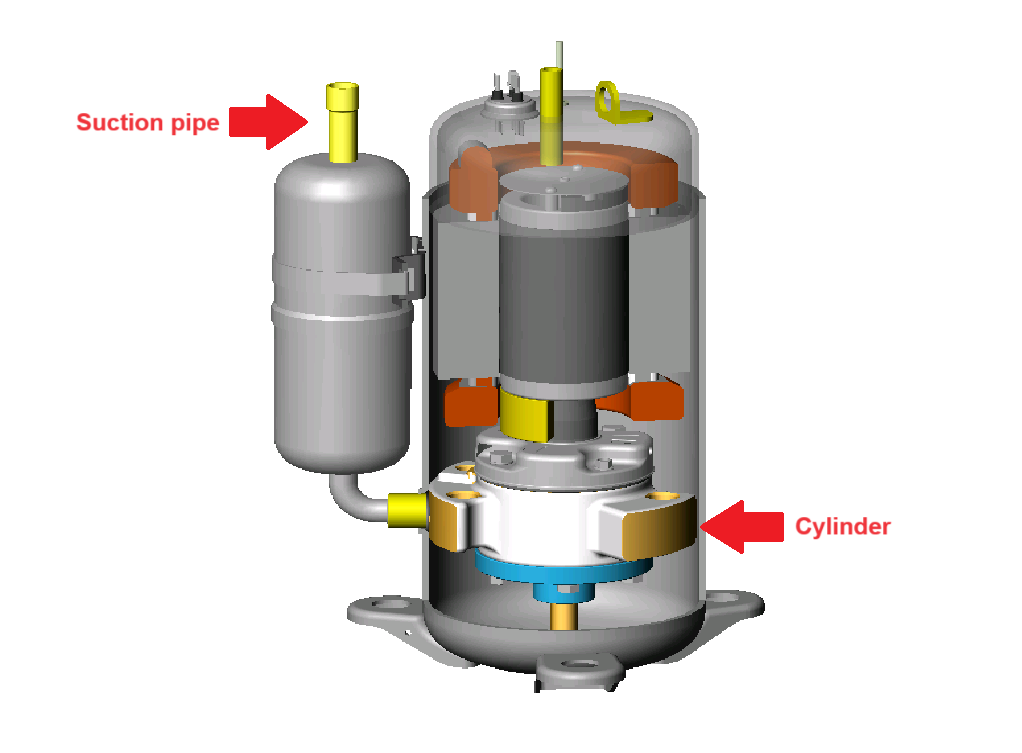

Because Sanyo compressor is a rotary compressor, the suction pipe goes directly into the compression chamber, that is, the cylinder. Please see the picture below:

If an oil separator is installed, instead it will cause oil hammer.

Because now the production and processing precision of rotary compressor is very high. The oil output is much less compared with piston compressors. If an oil separator is installed, there will be too much oil in the refrigeration system, thus cause oil hammer.

Panasonic scroll compressor outdoor condensing unit

The outdoor condensing unit features Panasonic scroll compressor with liquid injection technology, it has oil level sight glass and oil return connector, designed for medium temperature refrigeration and low temperature refrigeration. The minimum freezing temperature can reach -35°C.

- Refrigerant: R404A, R448A, R449A, R455A

- Power supply: 380V/50Hz, 3PH or 380V/60Hz, 3PH or 220V/60Hz, 3PH

- Cooling capacity: 4 HP to 6 HP

- Evaporating temp.: -5°C to -45°C

- Refrigerant: R404A, R448A, R449A, R455A

- Power supply: 380V/50Hz, 3PH or 380V/60Hz, 3PH or 220V/60Hz, 3PH

- Cooling capacity: 7 HP to 12.5 HP

- Evaporating temp.: -5°C to -45°C

For Panasonic scroll compressor outdoor condensing unit, the 4HP to 6HP outdoor condensing units are not installed the refrigeration oil separator, 7 HP to 12.5 HP outdoor condensing units are install an oil separator in refrigeration system.

So our customers will ask why 4HP to 6 HP outdoor condensing unit don’t install the refrigeration oil separator? Can we add the refrigeration oil separator?

Firstly, 4 HP to 6 HP Panasonic scroll compressor outdoor condensing unit can install the oil separator.

Why we don’t install oil separator in 4 HP to 6 HP Panasonic scroll compressor outdoor condensing unit?

There are TWO main reasons:

- Because the production and processing precision of the scroll compressor is very high now. The oil output is much less compared with piston compressors, large semi-hermetic compressors, screw compressors.

- And for 4HP to 6 HP outdoor condensing unit, the refrigeration system piping will not very long, so there is no problem with the oil return.

For 7HP to 12.5 HP Panasonic scroll compressor outdoor condensing units, the refrigeration system piping are longer, so it needs to add the oil separator to enhance the system oil return.

In outdoor condensing unit operation manual, there is refrigeration supplement suggestion.

If the length of the refrigeration system pipeline is less than 20 meters, it is not necessary to add refrigerant. If the length exceeds 20 meters, it is recommended to add it according to the table.

| Liquid Pipe Size | Refrigerant Add |

| 3/8 inch | 54 g/meter |

| 1/2 inch | 110 g/meter |

| 5/8 inch | 170 g/meter |

| 3/4 inch | 250 g/meter |

| 7/8 inch | 350 g/meter |

ZB Series Emerson Copeland Outdoor Condensing Unit

Outdoor condensing unit with ZB series Emerson Copeland scroll compressor, Emerson Copeland provides good performance ZB refrigeration scroll compressor for commercial refrigeration applications.

- Refrigerant: R404A, R448A, R449A, R455A

- Power supply: 220V~240V/50Hz, 1PH or 380V/50Hz, 3PH or 220V/60Hz, 3PH

- Cooling capacity: 2 HP to 7 HP

- Evaporating temp.: -25°C to 5°C

- Refrigerant: R404A, R448A, R449A, R455A

- Power supply: 380V/50Hz, 3PH or 380V/60Hz, 3PH or 220V/60Hz, 3PH

- Cooling capacity: 8 HP to 15 HP

- Evaporating temp.: -25°C to 5°C

- Refrigerant: R404A, R448A, R449A, R455A

- Power supply: 380V/50Hz, 3PH or 380V/60Hz, 3PH or 220V/60Hz, 3PH

- Cooling capacity: 20 HP to 25 HP

- Evaporating temp.: -25°C to 5°C

For ZB series Emerson scroll compressor outdoor condensing unit, the 2HP to 7HP outdoor condensing units are not installed refrigeration oil separator. The 8HP to 25HP outdoor condensing units are installed the oil separator.

Why 2HP to 7HP ZB series Emerson scroll compressor outdoor condensing unit don’t need to install the oil separator?

There are THREE main reasons:

- Now the production and processing precision of scroll compressor is very high. The oil output is much less compared with piston compressors, large semi-hermetic compressors, screw compressors.

- ZB series Emerson scroll compressor outdoor condensing unit is designed for medium temperature refrigeration and high temperature refrigeration. In medium temperature refrigeration condition and high temperature refrigeration condition, the system evaporation pressure is relatively high, the refrigerant flow rate in the pipe will increase. So the lubricating oil will flow along with the refrigerant and return to the compressor promptly and effectively.

- The refrigeration system piping of 2HP to 7HP outdoor condensing unit is not very long.

So 2HP to 7HP ZB series outdoor condensing units don’t need to install the refrigeration oil separator.

For 8HP to 25 HP ZB series Emerson Copeland condensing units, the refrigeration system piping are longer, so it needs to add the oil separator to enhance the system oil return.

In outdoor condensing unit operation manual, there is refrigeration supplement suggestion.

If the length of the refrigeration system pipeline is less than 20 meters, it is not necessary to add refrigerant. If the length exceeds 20 meters, it is recommended to add it according to the table.

| Liquid Pipe Size | Refrigerant Add |

| 3/8 inch | 54 g/meter |

| 1/2 inch | 110 g/meter |

| 5/8 inch | 170 g/meter |

| 3/4 inch | 250 g/meter |

| 7/8 inch | 350 g/meter |

ZF Series Emerson Copeland Outdoor Condensing Unit

Glen refrigeration offers Emerson outdoor condensing unit with ZF*KQE Compressor, designed for medium and low temperature commercial refrigeration, a wide range of cooling capacity options provide flexibility suitable for a variety of application.

- Refrigerant: R404A, R448A, R449A, R455A

- Power supply: 380V/50Hz, 3PH

- Cooling capacity: 3 HP to 7 HP

- Evaporating temp.: -40°C to 7°C

- Application: LBP and MBP

- Refrigerant: R404A, R448A, R449A, R455A

- Power supply: 380V/50Hz, 3PH

- Cooling capacity: 8 HP to 15 HP

- Evaporating temp.: -40°C to 7°C

- Application: LBP and MBP

- Refrigerant: R404A, R448A, R449A, R455A

- Power supply: 380V/50Hz, 3PH

- Cooling capacity: 18 HP

- Evaporating temp.: -40°C to 7°C

- Application: LBP and MBP

ZFI Series Emerson Copeland Outdoor Condensing Unit

Glen refrigeration manufactures good quality ZFI*KQE Copeland compressor condensing unit for cold room, freezer room, walk in cooler and walk in freezer. Copeland scroll compressor combined with vapor injection, provides cold room condensing unit first-in-class performance in low temperature refrigeration. The CoreSense control kits control the vapor injection superheat intelligently and ensures a safe discharge temperature.

- Refrigerant: R404A, R448A, R449A, R455A

- Power supply: 380V/50Hz, 3PH

- Cooling capacity: 3 HP to 7 HP

- Evaporating temp.: -40°C to 7°C

- Application: LBP and MBP

- Refrigerant: R404A, R448A, R449A, R455A

- Power supply: 380V/50Hz, 3PH

- Cooling capacity: 8 HP to 15 HP

- Evaporating temperature: from -40°C to 7°C

- Application: LBP and MBP

- Refrigerant: R404A, R448A, R449A, R455A

- Power supply: 380V/50Hz, 3PH

- Cooling capacity: 18 HP to 25 HP

- Evaporating temp.: -40°C to 7°C

- Application: LBP and MBP

ZSI Series Emerson Copeland Outdoor Condensing Unit

Glen refrigeration offers ZSI compressor Copeland Condensing Unit from 3 HP to 7 HP for positive and negative temperature applications. Emerson Copeland scroll compressor ensures excellent cooling performance while guaranteeing the high reliability.

- Refrigerant: R404A, R448A, R449A, R455A

- Power supply: 220V~240V/50Hz 1PH or 380V/50Hz, 3PH

- Cooling capacity: 3 HP to 7 HP

- Evaporating temp.: -30°C to 0°C

- Application: LBP and MBP

ZF series, ZFI series, ZSI series Emerson Copeland condensing units are used in low temperature refrigeration. As we mentioned above, in high temperature refrigeration system and medium temperature refrigeration system, the system evaporation pressure is relatively high, the refrigerant flow rate in the pipe will increase. So the lubricating oil will flow along with the refrigerant and return to the compressor promptly and effectively.

While in low temperature refrigeration system, when the evaporation pressure decreases, the boiling point of the refrigerant also decreases, causing the vaporization speed in the evaporator to slow down, thus affecting the flow rate of the refrigerant. In this case, the oil return of the refrigeration system will become more difficult, because the lubricating oil and the refrigerant circulate together. When the refrigerant flow rate slows down, the lubricating oil will also be difficult to return to the compressor quickly, which may cause insufficient lubrication of the system, thereby affecting the normal operation and efficiency of the system.

So it is proper that it needs to install a oil separator in low temperature outdoor condensing units.

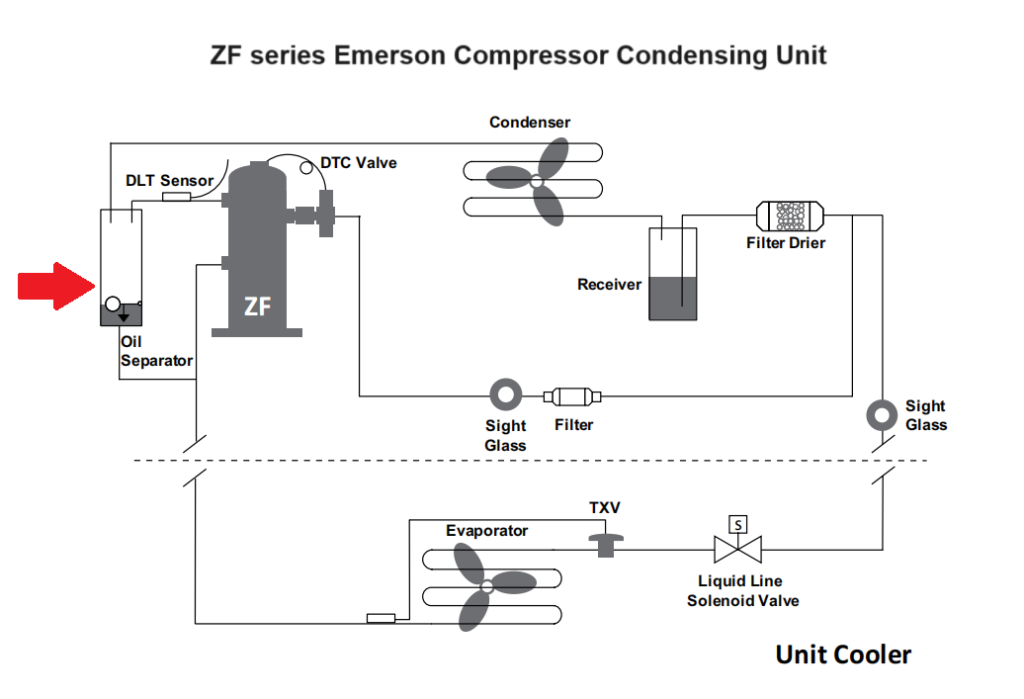

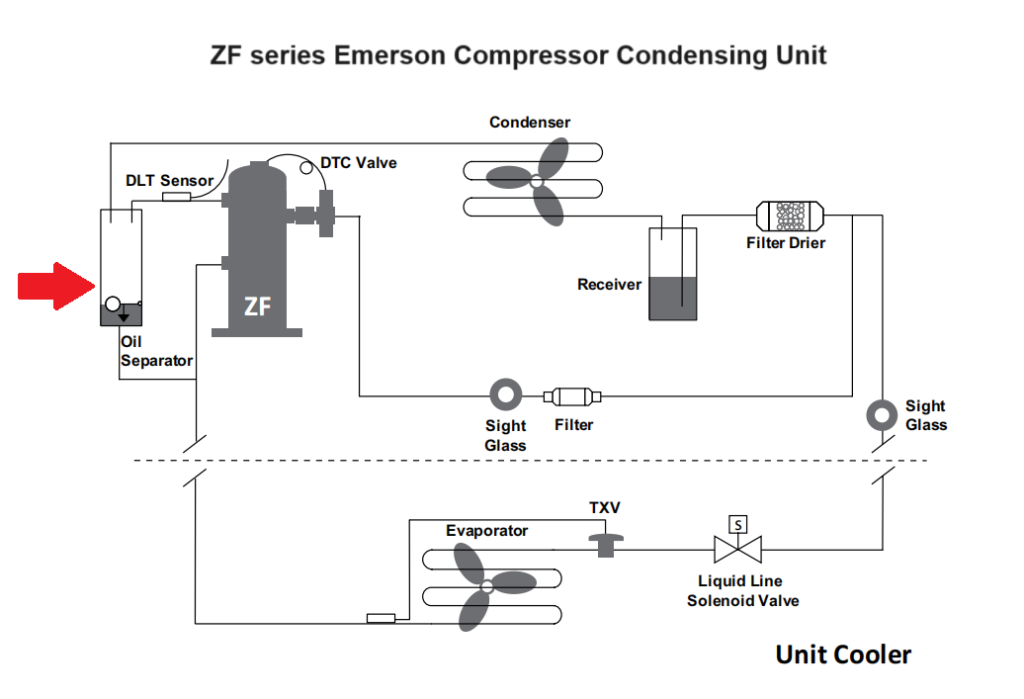

Where is the oil separator located in a refrigeration system?

The location of the oil separator is very important. It should be installed at the outlet of the compressor of the refrigeration system.

This is because the flow rate of the refrigerant at the outlet of the compressor is relatively large, and the oil separator can better separate oil and gas. It can also ensure the normal operation of the compressor.

If the condensing unit must put at 10~15 meters higher than the cold room and we have freezer application, the oil is able to return to the compressor?

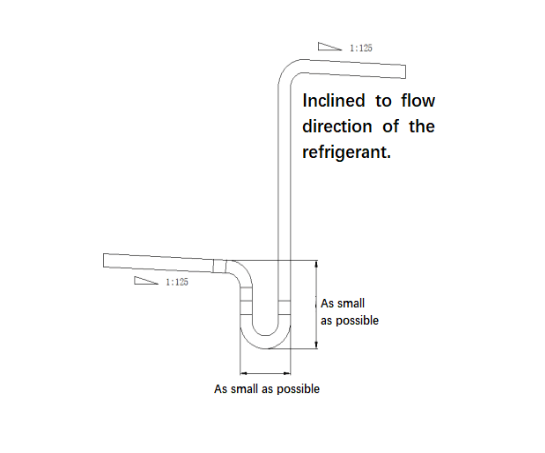

When the unit is installed higher than the cabinet or cold room, and the height difference is larger than 3 meters, It is necessary to install U-type oil return bend, and install an oil return bend every 6 meters when the height increases. The maximum height difference between the condensing unit and the cabinet (or cold room) should be less than 15 meters. The U-type bend can’t be installed between suction tube horizontal section, otherwise it will accumulate oil. Suction pipe horizontal section: The horizontal section of the suction pipe should be inclined to flow direction of the refrigerant. Inclines 1:125, so that the oil can return back to the compressor asap. Please see below:

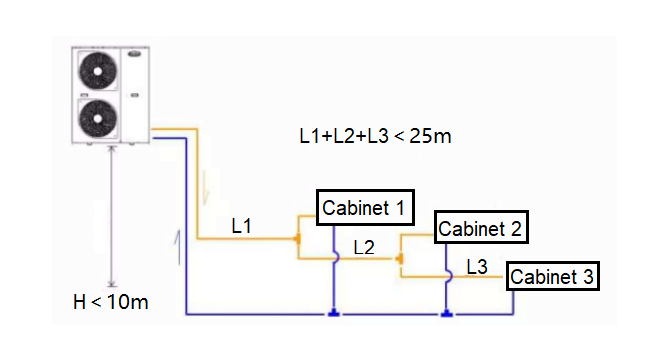

How many meters do you give for higher installation than the evaporator air cooler in freezers application?

The maximum height difference between the condensing unit and the cabinet is 10 meters, and the maximum piping length is 25 meters.

Hangzhou Glen Refrigeration Equipment Co., LTD focuses on R&D, production and sales of condensing units and refrigeration units, perfectly adapted to any commercial or industrial refrigeration applications.

The entire range of Glen Refrigeration condensing units include indoor condensing units, outdoor condensing units, air cooled condensing units, water-cooled condensing units, DC inverter condensing units, cold room evaporators, monoblock refrigeration units, and many other products. Our condensing units meet the European standards and CB standards.

Choosing an Glen Refrigeration condensing unit is the guarantee of an efficient and successful installation for any commercial refrigeration application, such as petrol stations, convenience stores, butcheries, bakeries, ice machines, cold rooms, milk tanks, restaurants, hotels, catering, kitchens etc. Glen Refrigeration has proudly served the food retailing industry with the most customer-focused solutions and innovations.

If you have any questions about the oil separator or oil return, feel free to contact us.

For inquiries about the outdoor condensing unit, email us at info@greehvacr.com

Or Whatsapp +86 15057108995