As we all know that the long-term and stable of the refrigeration compressor is inseparable from the good oil return.

For ordinary refrigeration system, most of the lubricating oil flows smoothly back to the compressor along with the refrigerant due to the short pipeline, so there is no oil return problem. However, due to the long pipeline, large drop, many elbows, and many places for oil storage in the multi compressor refrigeration system, it is difficult to return the oil. As the running time increases, the lubricating oil in the system accumulates more and more, and the compressor will be damaged due to lack of oil. Therefore, it is important to solve the oil return problem for multi compressor refrigeration system.

So the refrigeration oil separator is also an important part of a refrigeration system.

However, not all of the refrigeration systems need to install the oil separator.

So when are oil separators required? What type of refrigeration system requires an oil separator? We have already shared some views and experiences about the use of the oil separator refrigeration system. Please click to know more details:

If we want to understand “Why do We Need an Oil Separator for the Refrigeration System?”

We need to know:

What Is The Oil Separator In A Refrigeration System?

The oil separator is one of the refrigeration components in refrigeration system. It separates the refrigerant and lubricating oil.

We all know that the refrigeration compressor discharges high-temperature and high-pressure gas, which is actually a mixture of refrigerant and refrigeration oil. If the refrigerant enters into the system pipeline and is mixed with too much refrigeration oil, the heat exchange efficiency of the evaporator and condenser will be reduced. If the refrigeration oil stays in the pipeline and don’t return to the compressor quickly, the compressor will be easily damaged due to lack of oil.

In addition, if the refrigeration system pipeline is long, the use of an oil separator is essential for the normal oil supply of the compressor. That’s why our 2HP to 7HP Emerson condensing units are not installed the refrigeration oil separator, while our 8HP and above 8HP outdoor condensing units are installed the refrigeration oil separator.

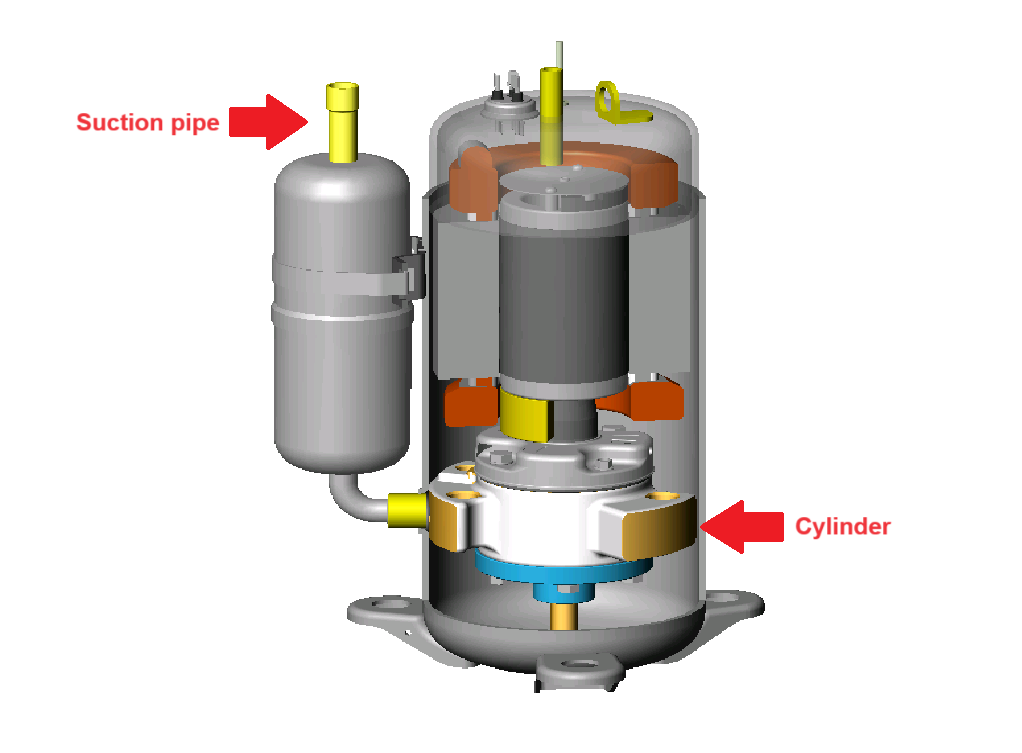

But not all outdoor condensing units required an refrigeration oil separator. The rotary refrigeration compressor outdoor condensing unit don’t need the oil separator.

Sanyo Compressor Outdoor Condensing Unit

- Refrigerant: R404A, R448A, R449A, R455A

- Power supply: 220V/50Hz, 1 PH and 220V/60Hz, 1PH and 380V/50Hz, 3 PH

- Cooling capacity: 1 HP to 3 HP

- Evaporating temp.: -5°C to -45°C

The outdoor condensing units adopts Sanyo rotary refrigeration compressor, with cooling capacity 1 HP, 1.5 HP, 2.5 HP and 3 HP. Sanyo compressor is a rotary vane compressor, the suction pipe of rotary valve compressor goes directly into the compressor cylinder. If there is too much oil in the refrigeration cycle, it will cause oil hammer. Another reason is now the production and processing precision of rotary compressor is very high. The oil output is much less compared with piston compressors. So the Sanyo rotary refrigeration compressor outdoor condensing unit don’t need the oil separator.

ZB Series Emerson Copeland Outdoor Condensing Unit

Outdoor condensing unit with ZB series Emerson Copeland scroll compressor, Emerson Copeland provides good performance ZB refrigeration scroll compressor for high temperature refrigeration and medium temperature refrigeration. 2HP to 7HP ZB series Emerson outdoor condensing units also don’t need the oil separator.

- Refrigerant: R404A, R448A, R449A, R455A

- Power supply: 220V~240V/50Hz, 1PH or 380V/50Hz, 3PH or 220V/60Hz, 3PH

- Cooling capacity: 2 HP to 7 HP

- Evaporating temp.: -25°C to 5°C

There are THREE main reasons:

- The refrigeration system pipeline of 2HP to 7HP outdoor condensing unit is not very long.

- We all know that the greater the flow rate and pressure of the refrigerant in the pipeline, the more beneficial it is to the return of the lubricating oil. ZB series Emerson scroll compressor is designed for medium temperature refrigeration and high temperature refrigeration. In medium temperature refrigeration condition and high temperature refrigeration condition, the system evaporation pressure is relatively high, the refrigerant flow rate in the pipe will increase. So the lubricating oil will flow along with the refrigerant and return to the compressor promptly and effectively.

- Now the production and processing precision of scroll compressor is very high. The oil output is much less compared with piston compressors, large semi-hermetic compressors, screw compressors.

What Is The Main Purpose of An Oil Separator?

The oil separator function is to separate the lubricating oil from the refrigerant. When the refrigerant vapor is discharged from the compressor, the lubricating oil is along with the refrigerant. If without the oil separator, the refrigeration oil will be enter into the condenser and evaporator along with the refrigerant, if there is too much oil in the refrigeration system, the condenser and evaporator heat exchange efficiency will be greatly reduced.

Due to the function of oil separator in refrigeration system, the refrigerant and lubricating oil will be separate in the oil separator, stay at the bottom of the separator, then back to the compressor through the pipeline between the compressor and oil separator.

How Does An Oil Separator Work In Refrigeration?

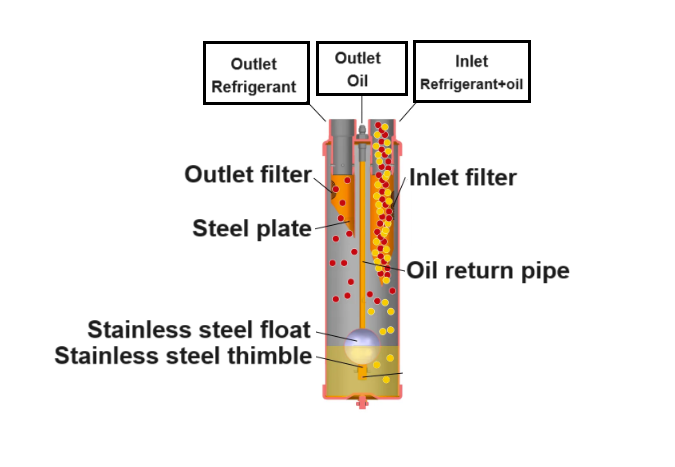

The oil separator working principle is according to the difference of the densities of the refrigerant and oil.

The densities of the lubricating oil and refrigerant vapor is different. When the refrigerant vapor discharged from the compressor, the lubricating oil is along with the refrigerant. Due to different densities, as well as the sudden expansion of the channel cross section, the sudden drop in air flow velocity, and the change in flow direction, so that the lubricating oil is separated and deposited at the bottom of the oil separator.

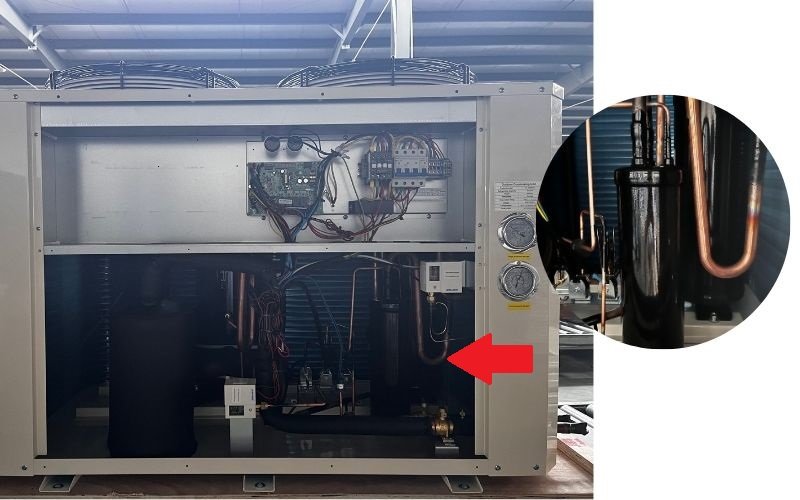

Where Is The Oil Separator Located In A Refrigeration System?

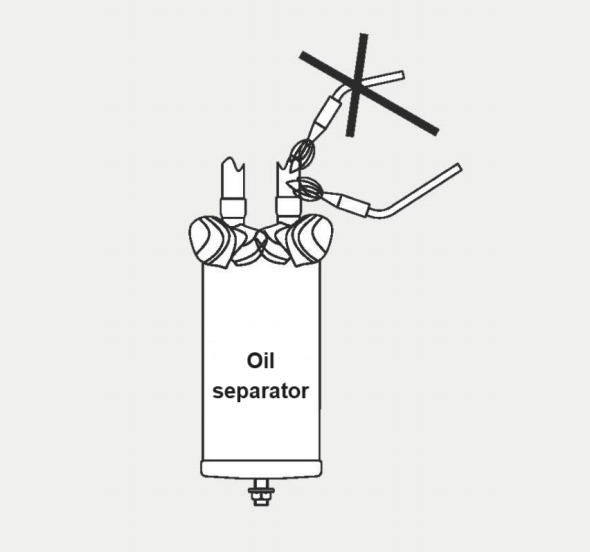

The oil separator must be installed between the compressor and condenser.

When install the oil separator, please pay attention to the following:

- Before installing the oil separator, it must be pre-charged with oil. The oil pre-charged must be same as the compressor oil.

- It must be installed vertically and close to the compressor to ensure the good performance of the oil separator.

- In order to prevent the refrigerant return from the condenser to the oil separator during off cycle of the system, it is recommend to install a check valve between the condenser and oil separator outlet.

- Avoiding chilling of the oil separator housing, the oil separator must be installed near the compressor,otherwise it will cause condensation of the refrigerant vapor inside of the oil separator.

- If it is impossible to install the oil separator near the compressor, it is better to takes some insulation measures.

What Are The Different Types of Refrigeration Oil Separators?

- Gravity oil separator

The gravity oil separator separates the oil from the refrigerant by gravity. It has a simple structure and is easy to use, but the separation effect is limited and it is difficult to remove small oil droplets. Therefore, it is mainly used in small refrigeration systems.

- Centrifugal oil separator

The centrifugal oil separator uses centrifugal force to separate the oil from the refrigerant. Due to its good separation effect, long service life, and convenient maintenance, it has gradually replaced the traditional gravity oil separator and become the mainstream equipment of the refrigeration system. The helical oil separator is the most common type. Please see the centrifugal separator diagram below:

- Filter oil separator

The filter oil separator separates the oil droplets through the filter. It is simple to operate and has a good separation effect, but the filter needs to be replaced frequently, and the maintenance cost is high.

- Membrane oil separator

The membrane oil separator uses a microporous membrane to screen and separate the oil droplets. It has a good separation effect and a long service life, but the cost is high.

Why do We Need an Oil Separator for the Refrigeration System?

- Ensure good oil return and the long-term and stable operation of the refrigeration compressor. We know that the operation of the compressor needs oil, otherwise the compressor will “burn out” due to wear and overheating.

- Avoid too much oil entering into the system pipeline and affect the heat exchange efficiency. In refrigeration cycle, if there is too much oil in the evaporator pipeline, after a long period of use, it will seriously affect its heat transfer effect and cause poor refrigeration.

- Low temperature refrigeration system needs an oil separator to ensure the oil return. Because in low temperature cycle, the evaporation pressure decreases, the boiling point of the refrigerant also decreases, causing the vaporization speed in the evaporator to slow down, thus affecting the flow rate of the refrigerant. In this case, the oil return of the refrigeration cycle will become more difficult, because the lubricating oil and the refrigerant circulate together. When the refrigerant flow rate slows down, the lubricating oil will also be difficult to return to the compressor quickly, which may cause insufficient lubrication of the system, thereby affecting the normal operation and efficiency of the system.

- Ensure good oil return when the refrigeration system pipeline is long. The oil return of long pipeline will be relatively difficult compared with that of short pipeline. If the oil can’t return to the compressor quickly, the compressor will be easily damaged due to lack of oil. Especially in the multi-compressor refrigeration system, due to the long pipeline and large drop, many elbows, and many places for oil storage in the multi-compressor system, the oil return is difficult. As the running time increases, the lubricating oil in the system accumulates more and more, and the compressor will be damaged due to lack of oil. In multi-compressor refrigeration system, the electronic oil level controller is used to control the balance of oil return.

In summary, oil return is very very important for a refrigeration system. If it is a oil separator refrigeration system, the oil separation efficiency of oil separator is very important. Find good quality refrigeration oil separator manufacturers, only by maintaining a good oil return state, your refrigeration equipment can run more smoothly.

Glen Refrigeration specializes in condensing units and monoblock refrigeration units for commercial refrigeration and cold storage. Whether you need basic condensing unit, or a custom refrigeration solution, Glen Refrigeration will be able to cater to your business’ requirements, including horizontal condensing unit, vertical condensing unit, outdoor condensing unit, indoor condensing unit, air cooled condensing unit, water cooled condensing unit, hot gas defrosting refrigeration systems, multi-compressor refrigeration system, cold room evaporator and so on.

Glen Refrigeration’s main goal is to meet our customer’s demands for refrigeration and freezing equipment with high reliability and high efficiency, and minimum service and maintenance costs. After years of experience, we know what our customers need, and we are more than qualified to provide the best service imaginable, and guarantee our customers satisfaction.

If you are interested in cooperating with us, do not hesitate to contact with us.

Email: info@greehvacr.com Or Whatsapp +86 15057108995

Let’s discuss how Glen Refrigeration can help you with complete commercial refrigeration system solutions!