The inverter technology is change the power supply frequency to adjust the motor speed, thereby reducing the power consumption, reducing losses and extending the service life of the equipment. It widely used in air conditioning, heat pump and commercial refrigeration.

The inverter condensing unit consists of inverter compressor, condenser, variable speed blower motor, receiver, high-pressure transducer, low-pressure transducer, filter dryer, accumulator, stop valve, controller, frequency controller, sight-glass and other refrigeration components.

The main difference from non-inverter condensing unit is the compressor. The non-inverter condensing unit adopts fix speed compressor, in which the compressor operates at only two speeds: 100% (the unit runs at full nominal power) or 0% (the unit is turned off).

While the inverter condensing unit adopts inverter driven compressor and the low-pressure transducer, controller and frequency controller. The inverter tech make the condensing unit cooling capacity modulation according to different refrigeration load, resulting in the ability to generate adequate cooling performance to the need of the commercial refrigeration. Unlike standard on-off and mechanical capacity modulation solutions, inverter technologie allows a significant energy consumption reduction.

When the cabinet target temperature reaches, the cabinet temperature controller will give the signal to the condensing unit, then the condensing unit turns off and the compressor stops running.

While if the refrigerated display cabinet adopts the inverter variable speed condensing unit, when the cabinet target temperature reaches, the controller will give the signal to the frequency controller, then the frequency controller lowers the compressor motor speed to maintain the temperature. The quantity of the compressor’s start and stop cycle is decreased. It also increases the compressor’s durability and minimizes the evaporators’ icing, which significantly decreases the overall energy consumption by reducing the amount of required defrost cycles.

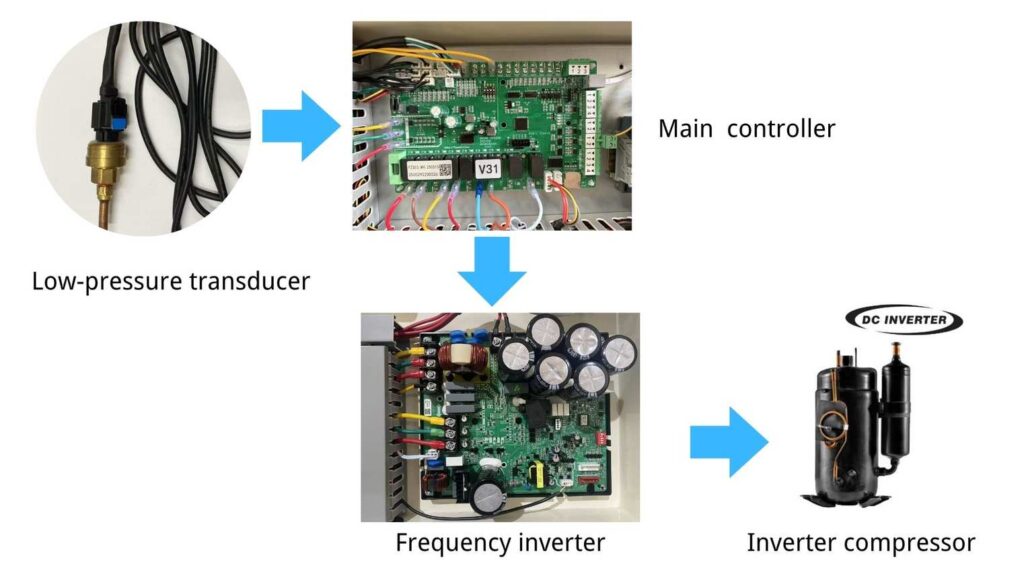

Inverter Technology-The Principle of Operation

The inverter technology mainly consists of low-pressure transducer, controller, frequency inverter, and inverter compressor.

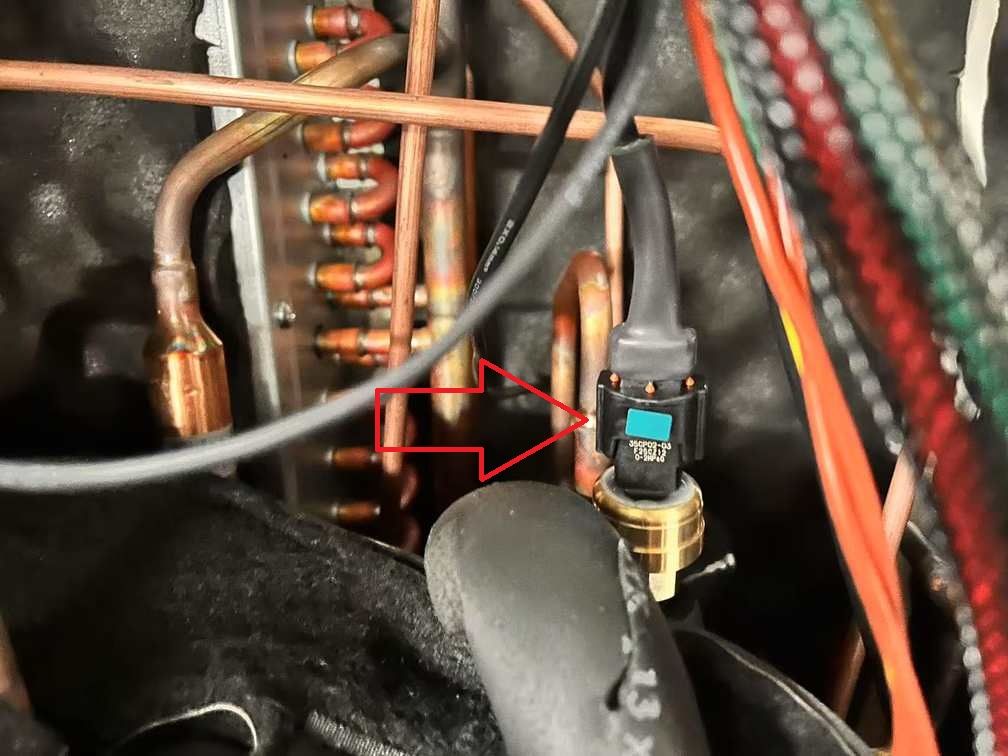

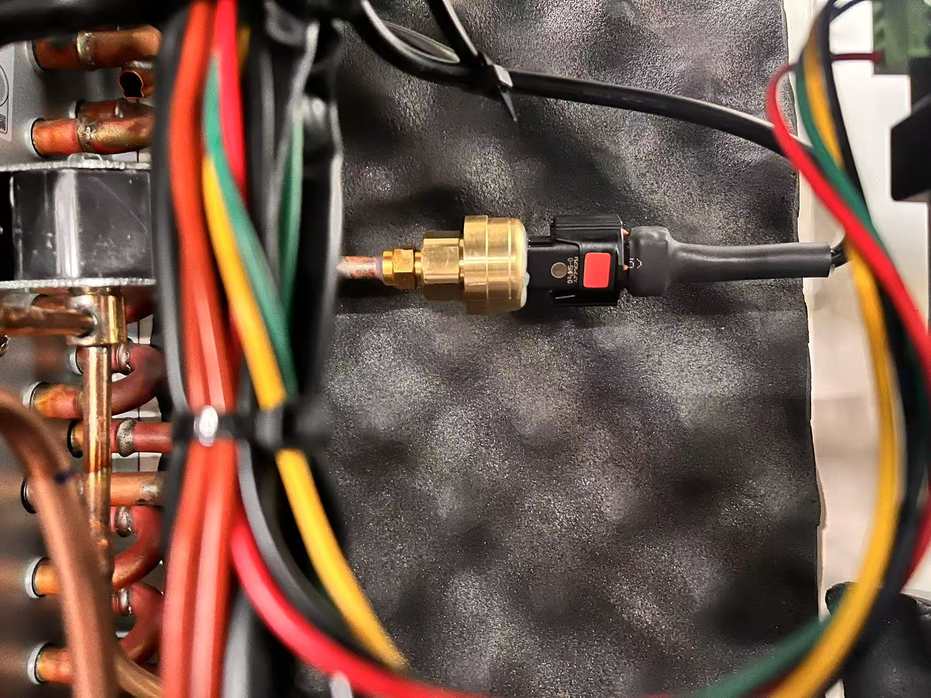

Low-pressure transducer

In the inverter refrigeration cycle, the low pressure transducer is an very important device. It is mainly used to detect the low pressure value. By sensing the low pressure value, the low pressure transducer converts it to a signal transmitted to the controller. The suction pressure rises or decreases with the rise or decrease of the temperature inside a cooling cabinet or chamber. By the controller and frequency controller, it can automatically adjust the compressor operating frequency and control the efficiency and stability of the refrigeration system.

To ensure the quantity of low-pressure transducer, Glen Refrigeration adopts famous brand Sensata low pressure sensor.

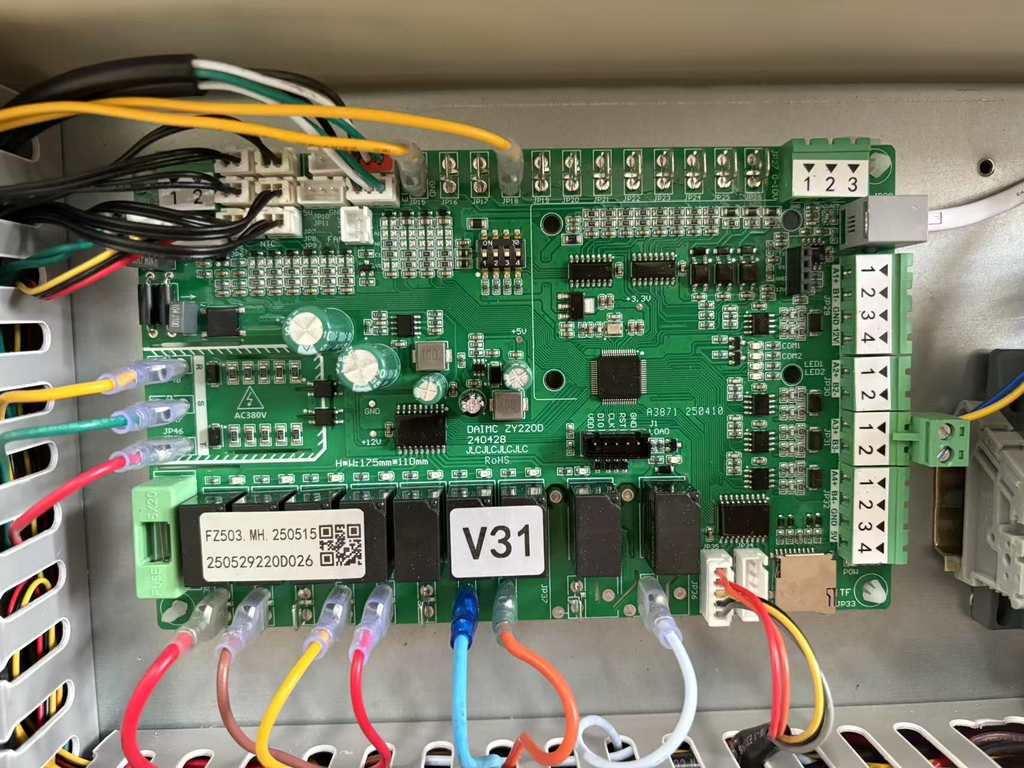

Controller

The controller is also called main controller, controller of the whole inverter condensing unit, just like the brain of people. When it receive the signal from the low-pressure sensor, it will make a judgment whether the compressor should speed up or slow down, then it will send the signal to the frequency controller to adjust the compressor speed.

The controller also regulates the condenser fan’s speed based on the signal from the high-pressure transducer. Except the variable speed refrigeration compressor, the inverter condensing unit also adopts variable speed blower motor to improve the efficiency and reduce the power consumption. The Sensata high pressure transducer will detect the high pressure value, converts it to a signal transmitted to the controller to adjust the condenser fan motor’s speed.

Frequency inverter

The frequency inverter is also called compressor driver. It receives the signal from the controller and adjust the compressor’s cooling capacity by controlling its rotation speed. Controller, compressor driver and variable speed refrigerant compressor and low-pressure transducer cooperate together. The low-pressure sensor detects the low pressure value, converts the pressure value to electric signal and sends to main controller, the main controller will provide the information to the compressor driver board to speed up or slow down the compressor’s speed.

The picture below is the controller and frequency inverter (also called compressor driver):

Inverter compressor

Inverter driven compressor is also called variable speed compressor or variable frequency compressor. It can be a inverter rotary compressor inverter scroll compressor, they are both common type in variable speed condensing unit. The compressor speed is adjusted according to the signal from controller to compressor drivers.

What is the Benefit of an Inverter Condensing Unit?

Lower energy consumption

Small start current. The variable speed inverter compressor’s soft starting draw small current from the power supply. While the fixed speed compressor draws 5~8 times the nominal current when start.

Reduce the number of start/stop. When the cabinet reaches target temperature, the non-inverter compressor stops; when the cabinet temperature rises to a certain degree above the set temperature, the compressor will automatically start and begin the refrigeration cycle. Every start will draw high current from the power supply, and start/stop frequently leads to high power consumption and stress on power supply, and on compressor mechanical parts. While the inverter variable speed condensing unit adopts the inverter technology, when the cabinet temperature reaches the target temperature, the variable speed technology keeps the compressor running at a low speed to maintain the cabinet temperature and not stops. Reducing the number of start/stop is reducing the power consumption, lower energy consumption, high efficiency condensing unit.

Capacity modulation

For a commercial refrigeration system, we will design based on peal cooling demand, but it is only a small percentage of the actual operation. For example, when a cold room or freezer room reaches the target temperature, the temperature of the cold room products is already low, so the heat load will be reduced accordingly. The cooling capacity demand will also be reduced.

If it is a normal fixed speed condensing unit, as it can’t adjust the compressor speed to adjust the cooling capacity, leading to efficiency losses and extra costs for oversized equipment.

While a Inverter condensing unit with the bldc inverter compressor can modulate the cooling capacity to match the cooling demand by the variable speed drive technology.

Soft starting, increasing compressor durability. The fixed speed compressor has a large starting current, it is not good for both power grid and also the compressor. However, the soft starting of the variable frequency compressor , reduces the impact on the power grid and extends the motor life by 2-3 times; the maintenance cost is lowered, while the production efficiency is higher, a win-win situation!

Inverter ac vs non inverter, inverter condensing units did a good job in energy saving and increasing reliability. At same time, it provides more precise temperature regulation.

Energy efficiency is no longer an option. Glen Refrigeration is committed to energy saving refrigeration solutions. We developed the inverter air cooled condensing unit, inverter water cooled condensing units, parallel-compressor condensing unit.

- Low Profile Horizontal Inverter Condensing Unit from 1HP to 3 HP

The horizontal inverter condensing unit from 1 HP to 3 HP are designed for refrigerated display cabinet. Featuring Sanyo inverter rotary compressor and EBM EC fan, they are cooperating with compressor inverter controller to provide a high efficiency refrigeration.

| Model | Refrigerant | Power Supply | Cooling Capacity |

| GL-BHSN10EL | R404A, R448A, R449A | 220V/50Hz~60Hz, 1PH | 1 HP |

| GL-BHSN20EL | R404A, R448A, R449A | 220V/50Hz~60Hz, 1PH | 2 HP |

| GL-BHSN30EL | R404A, R448A, R449A | 220V/50Hz~60Hz, 1PH | 3 HP |

| GL-BHSR10EL | R290 | 220V/50Hz~60Hz, 1PH | 1 HP |

| GL-BHSR20EL | R290 | 220V/50Hz~60Hz, 1PH | 2 HP |

| GL-BHSR30EL | R290 | 220V/50Hz~60Hz, 1PH | 3HP |

Please click here for more details: Horizontal Inverter Condensing Unit from 1 HP to 3 HP

- Inverter Outdoor Condensing Unit from 3 HP to 10 HP

The outdoor inverter condensing unit adopts Sanyo inverter rotary compressor, Panasonic inverter scroll compressor, Hitachi inverter scroll compressor, collaborate with controller and inverter compressor drive to ensure significant energy cost reductions and increased reliability.

| Mode | Refrigerant | Power Supply | Cooling Capacity |

| GL-BSN30EL | R404A, R448A, R449A | 220V/50Hz~60Hz, 1PH | 3 HP |

| GL-BSN40FL | R404A, R448A, R449A | 380V/50Hz~60Hz, 3PH | 4 HP |

| GL-BRN60FL | R404A, R448A, R449A | 380V/50Hz~60Hz, 3PH | 6 HP |

| GL-BRN70FL | R404A, R448A, R449A | 380V/50Hz~60Hz, 3PH | 7 HP |

| GL-BSN80FL | R404A, R448A, R449A | 380V/50Hz~60Hz, 3PH | 8 HP |

| GL-BRN100FL | R404A, R448A, R449A | 380V/50Hz~60Hz, 3PH | 10 HP |

Please click here for more details: Inverter Outdoor Condensing Unit from 3 HP to 10 HP

- Low Profile Water Cooled Inverter Condensing Unit from 1 HP to 3 HP

By using Sanyo inverter rotary compressor and plate heat exchanger, Glen Refrigeration offers water cooled inverter condensing unit from 1 HP to 3 HP compared to traditional on-off compressor condensing unit.

| Model | Refrigerant | Power Supply | Cooling Capacity |

| GL-BHSN10EL-SL | R404A, R448A, R449A | 220V/50Hz~60Hz, 1PH | 1 HP |

| GL-BHSN20EL-SL | R404A, R448A, R449A | 220V/50Hz~60Hz, 1PH | 2 HP |

| GL-BHSN30EL-SL | R404A, R448A, R449A | 220V/50Hz~60Hz, 1PH | 3 HP |

| GL-BHSR10EL-SL | R290 | 220V/50Hz~60Hz, 1PH | 1 HP |

| GL-BHSR20EL-SL | R290 | 220V/50Hz~60Hz, 1PH | 2 HP |

| GL-BHSR30EL-SL | R290 | 220V/50Hz~60Hz, 1PH | 3HP |

Please click here for more details: Water Cooled Inverter Condensing Units from 1 HP to 3 HP

Water Cooled Inverter Condensing Unit from 3 HP to 10 HP

The innovation inverter technology offers new new opportunities for commercial refrigeration systems, water cooled inverter condensing unit offers energy efficient and reduced energy consumption to replace traditional rack refrigeration system.

| Mode | Refrigerant | Power Supply | Cooling Capacity |

| GL-BSN30EL-SL | R404A, R448A, R449A | 220V/50Hz~60Hz, 1PH | 3 HP |

| GL-BSN40FL-SL | R404A, R448A, R449A | 380V/50Hz~60Hz, 3PH | 4 HP |

| GL-BRN60FL-SL | R404A, R448A, R449A | 380V/50Hz~60Hz, 3PH | 6 HP |

| GL-BRN70FL-SL | R404A, R448A, R449A | 380V/50Hz~60Hz, 3PH | 7 HP |

| GL-BSN80FL-SL | R404A, R448A, R449A | 380V/50Hz~60Hz, 3PH | 8 HP |

| GL-BRN100FL-SL | R404A, R448A, R449A | 380V/50Hz~60Hz, 3PH | 10 HP |

Glen Refrigeration’s main goal is to meet our customer’s demands for refrigeration and freezing equipment with high reliability and high efficiency, and minimum service and maintenance costs. After years of experience, we know what our customers need, and we are more than qualified to provide the best service imaginable, and guarantee our customers satisfaction.

If you are interested in cooperating with us, do not hesitate to contact with us.

Email: info@greehvacr.com Or Whatsapp +86 15057108995

Let’s discuss how Glen Refrigeration can help you with complete commercial refrigeration system solutions!