What is Refrigeration System?

Refrigeration system definition: A refrigeration system is a technology that transfer the heat from one place to another place. For example, the refrigerating system transfers the heat from inside of the refrigerator to outside of the refrigerator, thus reduces the temperature inside the refrigerator and achieves refrigeration.

According to different principle of refrigeration, there are different types of refrigeration systems, including vapor compression refrigeration, absorption refrigeration, evaporative refrigeration system.

Vapor Compression Refrigeration System

Vapor compression refrigeration system is also called mechanical refrigeration system. As the name implies, mechanical refrigeration system transfers heat by mechanically compressing low-temperature low-pressure refrigerant into high-temperature high-pressure refrigerant. The refrigerant absorbs heat when they evaporate into a gas and release heat when they condense into a liquid.

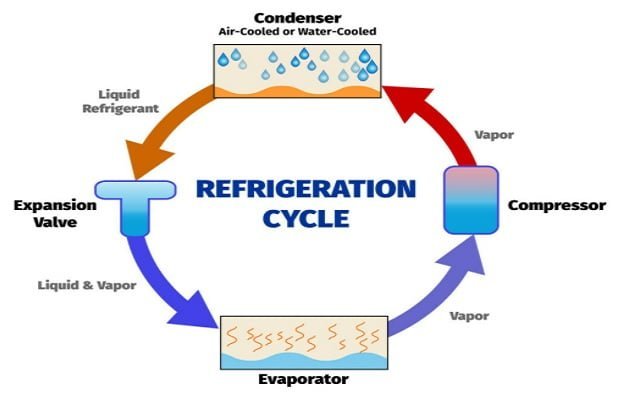

The compression refrigeration cooling system widely used in air-conditioning, commercial refrigeration and industrial refrigeration. It is a refrigeration cycle, made of 4 major refrigeration system components. They are refrigeration compressor, condenser, expansion device, and evaporator. Compressor is the heart of the refrigeration circuit, compresses the low-pressure refrigerant into high-temperature high-pressure, then discharge it to the condenser. The refrigerant condenses in the air cooled condenser or water cooled condenser and turns into medium-temperature high-pressure refrigerant. Through the capillary or expansion device, the refrigerant goes into evaporator. It evaporates and absorb heat in evaporator, thus reduces the temperature inside the refrigerator or cold room and achieves refrigeration. How does a refrigeration system work? Please see the compression refrigiration system diagram below:

Absorption Refrigeration

The absorption refrigeration cycle is mainly composed of four exchange components, generator, condenser, evaporator, absorber, pump, throttle valve and other components. The condenser, throttle valve and evaporator are similar to the compression refregeration system. The generator and absorber are equivalent to the compressor of the compression refrigerant system.

The principle of heat absorption refrigeration system is unlike mechanical compression refrigerant systems. It relays on the process of absorption and heating, rather than an mechanical compressor to move the low-pressure side to high-pressure side.

For example, the refrigeration absorption system use use ammonia as the refrigerant and water as the absorbent. The water is stored in an absorber, it draws ammonia from the low-pressure side of the system and removes heat while absorbing the ammonia. The pump delivers the aqueous ammonia solution to the generator. In the generator, the ammonia is separated from the water by heating and boiling, then delivered to the high-pressure side. Please see the absorption refrigeration diagram below:

Vapor compression refrigeration is the most common in commercial refrigration system and industrial refrigeration system. There are many different types of vapor compression refregeration, including domestic refrigeration system, commercial refrigeration system and industrial refrigeration system. Domestic refrigeration system is the most basic refrigeration. The commercial refridgeration system includes self contained refrigeration system, cold room refrigeration system, monoblock refrigeration system, dual compressor refrigeration system, air cooled refrigeration system and water cooled refrigeration system. All of them are used to reduce the temperature of the food to extend the shelf life during food storage and process refrigeration. The applications of industrial refrigeration systems include various fields such as medicine and food process refrigeration. Many medical equipment need to maintain a low temperature environment, such as frozen cells, test tubes, etc.

As mentioned above, the vapor compression refridgeration systems can be classified:

Domestic Refrigeration System

Domestic refrigeration system mainly refer to the home refrigerator system. Home refrigerator system is the most basic refrigeration cycle in compression refrigerant systems. According to different structure, the home refrigerator system can be divided into direct and indirect refrigeration system.

- Direct Refrigeration System

The direct cooling refrigeration system widely used in home refrigerator. Direct cooling refrigeration means the evaporator is in direct contact with the inner wall of the refrigerator chamber for heat exchange, without the helpful of evaporator fan in refrigerator cycle. These evaporators are composed of S-shaped coils. In the refrideration cycle, the medium-temperature and high-pressure liquid refrigerant becomes low-temperature and low-pressure liquid refrigerant after being throttled, then enters into the evaporator S-shaped coil to evaporate and absorb the heat from food.

- Indirect Refrigeration System

The indirect refrigeration system in home refrigerator refers to air cooled refrigeration system. The main difference between direct and indirect refrigeration system is that the indirect refrigeration system has evaporator fans. When the low-temperature low-pressure liquid refrigerant enters into the evaporator coil, the cold air is blown into the refrigerator chamber, makes the heat exchange faster and cooling faster.

Commercial Refrigeration System

Commercial Refrigeration System refers to the refigeration system for commercial refrigerating equipment, including commercial refrigerators, commercial freezers, refrigerated display cases, cold rooms, freezer rooms and many other commercial refrigeration equipment used in supermarket, restaurant, hotel, food processing factory and so on. According to different applications, it includes monoblock refrigeration system for commercial refrigerator and freezer, monoblock refrigeration system for worktop chiller and freezer, vending machine refrigeration system, self contained refrigeration system for refrigerated display cases, remote refrigeration system for cold room, dual compressor refrigeration system for commercial refrigerating equipment and so on.

Monoblock Refrigeration System for Commercial Refrigerator and Freezer

The top mount monoblock refrigeration system are designed for stainless steel refrigerator and freezer. It integrates the refrigerator compressor, condenser, expansion device, and evaporator into a referigeration cycle. It is a sealed refrigeration system, pre-charged with refrigerant, which work directly as long as it is powered on.

Monoblock Refrigeration System for Worktop Chiller and Freezer

The monoblock refrigeration system, designed by side mount according to the worktop chiller and freezer application. It is a packaged refrigeration system, composed of refrigerator compressor, condenser, capillary and evaporator, which are 4 major parts of refrigeration loop system. With integrated design and pre-charged refrigerant, it is very convenient for customer to install and use.

Vending Machine Refrigeration System

The bottom mount monoblock refrigeration unit and top mount monoblock refrigeration unit are widely used in vending machine refrigeration. They have similar structure, composed of the 4 major parts of the refregeration system. Just the installation place are different. The bottom mount monoblock refrigeration unit is installed at the bottom of the vending machine; while top mount monoblock refrigeration unit is installed on the top of the vending machine.

Self Contained Refrigeration System

The self contained refrigeration system is relative to the remote refrigeration system. Self contained refrigeration system means the cooling refrigeration system installed inside of the commercial refrigeration equipment. It mainly refer to the condensing unit. In self contained refrigeration system, the air cooled condensing unit or water cooled condensing unit generally installed at the bottom of the commercial refrigeration equipment or top of the commercial refrigerating equipment.

Water Cooled Refrigeration System

Water cooled refrigeration system, as the name implies, it uses water as the cooling media. While the water cooled condenser is used to replace the air cooled condenser. When the high-temperature high-pressure vapor refrigerant enters into the water cooled condenser, the chilled water absorbs the heat dissipated from the vapor refrigerant and reduces its temperature. The water loop system is composed of water cooled condensing unit, expansion device, evaporator, water pump and dryer cooler (or cooling tower). Compared with air cooled refrigerator systems, the water cooling refrigeration system has an extra water pump and dryer cooler, because the water needs to be cooled during the refrigeration circuit.

Cold Room Refrigeration System

Cold room refrigeration systems widely used in different cold rooms and freezer rooms. They constitutes a huge amount of commercial refrigeration, includes meat cold storage, vegetable cold storage, fruit cold storage, milk cold storage, ice cream cold storage, blast freezing process, and so on. These cold rooms and freezer rooms all need refigeration system to keep them storage and keep fresh. Most of the cold room refrigeration systems are composed of split condensing unit and evaporator. The condensing unit is installed outside of the cold room or building, it is also called outdoor condensing unit or remote condensing unit or cold room outdoor unit. The evaporator is installed inside of the cold room, so it is also called cold room indoor unit. Different sizes of cold rooms, the refrigeration systems are different. The refrigeration system must be selected according to the actual needs of the cold storage project construction.

Monoblock Refrigeration System (Wall Mount) For Cold Room

The wall mount monoblock refrigeration unit is designed for small and medium cold room and freezer room. It is a packaged refrigeration unit, integrates the refrigeration compressor, condenser, expansion valve, evaporator. With pre-charged refrigerant, it is a convenient solution for cold room and freezer room.

Monoblock Refrigeration System (Top Mount) for Cold Room

The TOP MOUNT monoblock refrigeration system, designed to locate on the top of the cold room or freezer room. It features low height, integrated design, pre-charged refrigerant, help business owners to install and use conveniently and save the installation fee.

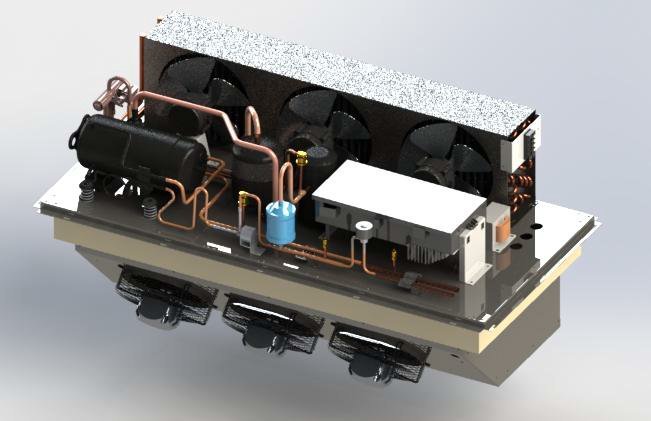

Dual Compressor Refrigeration System

Dual compressor refrigeration system is designed to remotely locate all individual refrigeration systems to a single system for increase efficiency. For example in a supermarket, each piece of refrigeration equipment such as refrigerated display cases, upright freezers, has its own refrigeration system. Each one of these systems releases heat into the surrounding environment. In turn, this heat increases the load on the air conditioning system, resulting in higher energy usage. By combining all these individual refrigeration systems into one remote system. The dual compressor refrigeration system can help business owners to remove the heat and reduce their air conditioning load, also reduce inside noise level and extend the life of equipment.