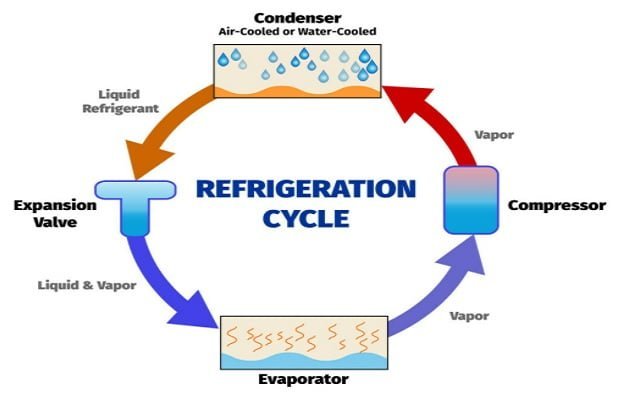

Generally, the refrigeration cycle is composed of refrigeration compressor, condenser, throttling device, evaporator. They are 4 major refrigeration cycle components, are connected by copper tube into a sealed refrigeration system and is charged with refrigerant.

Refrigeration System Compressor

In the 4 major refrigeration cycle components, refrigeration system compressor is the most important part, likes the heat of human. It also likes a pump, provides the power needed for the refrigerant to circulate through the refrigeration cycle.

Without the compressor, the refrigeration system can’t work normally. What does the compressor do in the refrigeration system? The function of a compressor in a refrigeration system is as follow:

Draw low-pressure low-temperature vapor refrigerant from the evaporator.

Compress the low-pressure and low-temperature refrigerant vapor into a high-pressure and high-temperature superheated vapor.

Discharge and push the refrigerant to flow in the system to complete the refrigeration cycle.

There are different types of compressors used in refrigeration system, including the piston compressor, rotary compressor, scroll compressor and screw compressor. These four types of compressors mainly used in air conditioning, commercial refrigeration and industrial refrigeration.

Condenser

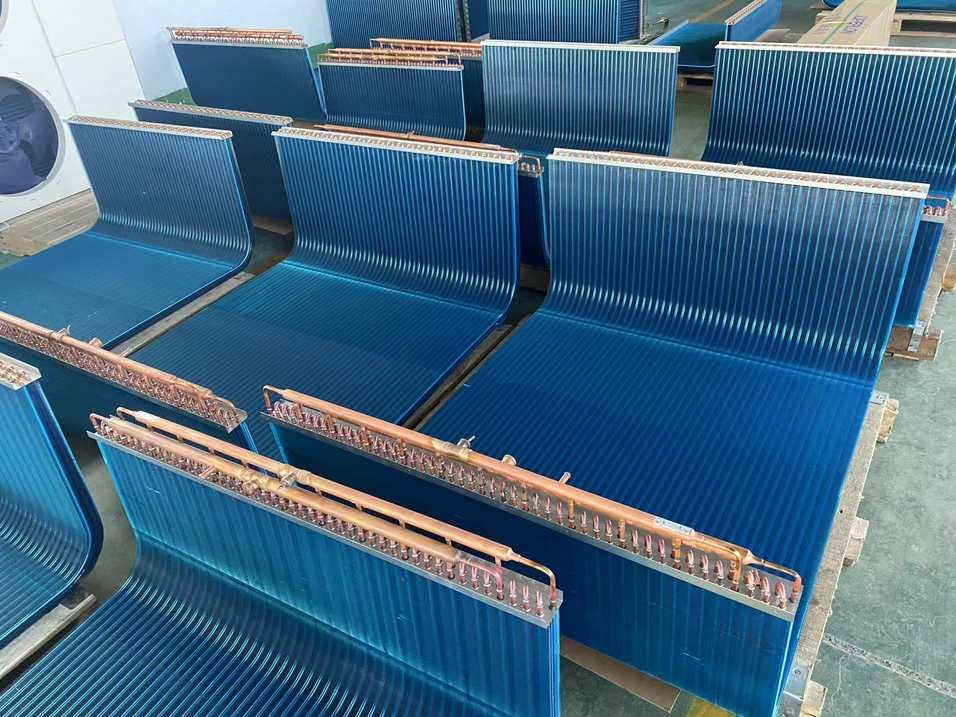

Condenser is one of the 4 Major Refrigeration Cycle Components. It is one kind of heat exchanger in refrigeration system.

Compressor draw the low-temperature low-pressure vapor refrigeration from evaporator, compress into high-temperature high-pressure vapor refrigerant, then discharge the refrigerant to the condenser. The function of condenser in refrigeration system is to change the high-temperature high-pressure gas refrigerant to medium-temperature high pressure liquid refrigerant. The heat of refrigerant will be dissipated through the condenser fan and aluminum foils.

Copper tube condenser will be used in refrigeration cycle frequently, because of good thermal conductivity of copper pipe. In order to improve the efficiency of the condenser, all of Glen Refrigeration’s condensers use internally grooved copper tubes to replace the normal smooth cooper tubes. The copper tube surface will add the Blue Hydrophilic Aluminum Foil to increase the heat dissipation area to accelerate heat dissipation, and the air convection is accelerated through the fan to take away the heat.

The hydrophilic aluminum foil is a treated by a special process, with a layer of hydrophilic layer coated on the surface. Compared with normal aluminum foil, it increases the heat exchange area, speeds up the cooling and heating speed, and also avoids the noise caused by condensed water blocking the air flow.

In addition, plate heat exchanger and shell and tube water cooled condenser are widely used in water cooled condensing unit.

Micro-channel condensers are widely used in R290 condensing unit. Because the R290 refrigerant charge is much less than R404A, compared with Copper tube condenser, micro-channel condenser features high efficiency.

The condensation in refrigeration system converts the high-temperature vapor refrigerant into a medium-temperature liquid. However, the high pressure of the refrigerant remains unchanged (the refrigerant cooled in the condenser is a normal temperature, high pressure liquid).

Throttling Device

Throttling is one of the four main processes in refrigeration system. The main functions of throttling device are : (1) Reduce the pressure of the high-pressure liquid refrigerant coming out of the the condenser; (2) Adjust the amount of refrigerant liquid entering into the evaporator according to the system load.

There are three main kinds of throttling device used in refrigeration cycle, Capillary refrigeration system, Thermal Expansion Valve and Electronic Expansion Valve (EEV).

Capillary tube is the simplest throttling device in refrigeration system. It is a a slender copper tube with an inner diameter of 0.4~2.0mm. Because of its low price and flexible selection, it is widely used in small refrigeration cycle. The throttling characteristic of the capillary refrigeration system is realized by utilizing the resistance of the refrigerant flowing in the thin and long tube.

As a throttling device, the capillary tube in refrigeration system has the advantages of simple structure, convenient manufacture, low price and not easy to break down. Moreover, after the compressor stops, the pressure of the condenser and the pressure of the evaporator can automatically reach a balance, which reduces the load when restart the compressor. But the capillary tube size is constant (the inner diameter and length of the capillary), the refrigerant flow rate cannot be adjusted, so the capillary is only suitable for small refrigeration systems.

Thermal expansion valves, one kind of refrigerant control devices. They are commonly used in Freon refrigeration systems. Through the action of the temperature sensing bulb, they will automatically change with the temperature of the refrigerant at the outlet of the evaporator to achieve the purpose of adjusting the liquid supply of the refrigerant.

The working principle of the electronic expansion valve in refrigeration system is based on the detection and data collection of multiple parameters such as the degree of superheat or the temperature difference between the inlet and outlet air, the return air temperature and its set value, and after being processed by the Electronic Expansion Valve Controller, an instruction is issued to control the electronic expansion valve opening to meet the system load requirements.

The electronic expansion valve is one types of expansion valves in refrigeration system, adjust the flow of refrigerant entering the refrigeration device according to a preset program. In some occasions where the load changes sharply or the operating range is wide, traditional throttling elements (such as capillary tubes, thermal expansion valves, etc.) can no longer meet the requirements of comfort and energy saving. The electronic expansion valve is a good choice and now it is more and more widely used in refrigeration cycle.

Evaporator

The refrigeration evaporator is an important refrigeration cycle components. The evaporator function in refrigeration system is to evaporate the liquid refrigerant into a gas, thereby absorbing the heat in the air and achieving the purpose of refrigeration.

The low-pressure liquid refrigerant coming out from the throttling device, enters into the evaporator, absorbs the heat in the air through the tube wall then evaporates. The low-pressure liquid refrigerant changes to low-temperature low-pressure vapor refrigerant.

Refrigeration system compressor, condenser, throttling device and evaporator are 4 main components of a refrigeration system. It is very important that all of these components are in place and working effectively.

Monoblock Refrigeration Unit

The monoblock refrigeration unit is a refrigeration system cycle including the refrigerator compressor, condenser, throttling device (capillary or electronic expansion valve), evaporator and other refrigeration system accessories.

Glen refrigeration offers top mount refrigeration unit, side mount refrigeration unit, bottom mount refrigeration unit, vending machine refrigeration unit and wall mounted refrigeration unit.

Top mount refrigeration unit is a kind of monoblock refrigeration unit, installed on the top of commercial refrigeration equipment. They widely used in stainless steel upright refrigerator and freezer, kitchen refrigerator and freezer. Click here for more details.

Side mount refrigeration unit is specially designed for worktop refrigerator and freezer. The compact size and easy installation make it high desirable in commercial refrigeration market. More product information, please click here.

The bottom mount refrigeration unit includes the vending machine refrigeration unit and cake display cabinet refrigeration unit. They are all installed at the bottom of the refrigeration equipment. So the seal between the refrigeration unit and cabinet is very important. Click here for more information.

Glen refrigeration offers wall mounted refrigeration unit for small and medium size cold room, freezer room, walk in cooler and walk in freezer. Want to learn more?

If you have any questions about the Water Dispenser cooling system, we are here to help!

Contact us by email or fill out the contact form below.

Email: info@greehvacr.com

Whatsapp: 0086 15057108995

We look forward to your inquiry!