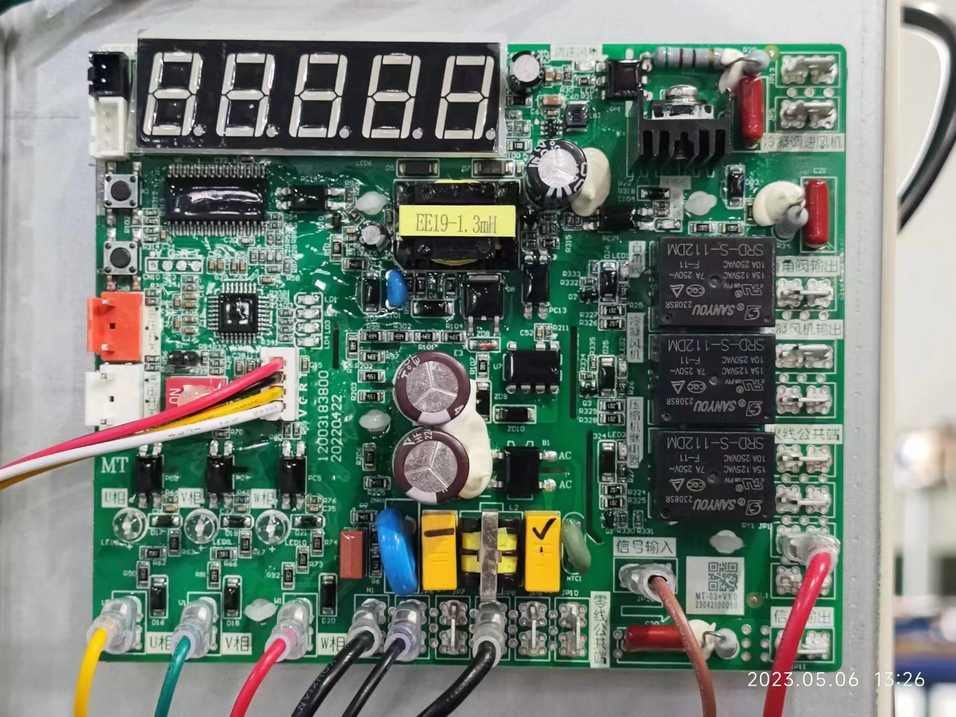

Control Board For 1 HP to 7 HP Outdoor Condensing Unit

Glen Refrigeration offers the outdoor condensing unit with intelligent control board technology. The control board for the outdoor condensing unit, likes the brain of human. It integrates many functions:

- Discharge temperature over-high protection

- High pressure protection

- Low pressure protection

- Phase sequence protection

- Fan speed regulation

- Start frequently protection