Cold storage refrigeration is a kind of facilities that use refrigeration system to control and maintain at a stable temperature in the cold storage room. These systems are widely used to preserve food, frozen products, pharmaceuticals, and other temperature-sensitive goods by preventing spoilage and maintaining product quality. It consists of condensing unit, evaporator unit, expansion valve, cold room temperature controller, cold room panels and so on. The cold storage refrigeration system is the heart of the cold storage refrigeration.

The cold storage design is according to the cold storage temperature, cold room size, application, and ambient conditions and so on. Based on these conditions, Glen Refrigeration will provide a cold storage refrigeration solution with high reliability and energy efficiency for commercial and industrial cold rooms.

The main components of a cold storage refrigeration include condensing unit, evaporator unit, expansion valve, cold room temperature controller and cold room panels and so on. The cold storage condensing unit and evaporator produce cold air to cold storage room. The cold room controller is the brain of the cold storage, it controls the refrigeration system ON and OFF according to target temperature. Cold room panel has a certain insulation performance, its function is to keep the cold air produced by the refrigeration system from leaking out of the cold storage room and maintain the stability of inner temperature.

The condensing unit is one of the main cold storage refrigeration equipment in the cold storage systems refrigeration. It is including cold storage compressor, condenser, fan motor, receiver, sight-glass, solenoid valve, high and low pressure switch, high and low pressure gauge, accumulator, stop valve and so on. Some of condensing units also have oil separator. Among these parts, compressor is the heart of the cold storage condensing unit. A good-quality refrigeration compressor is the key of the cold storage condensing unit. That’s why Glen Refrigeration always continue to use Sanyo, Panasonic and Copeland compressor. They are all famous brands and of high quality.

Glen Refrigeration provides different series of condensing units for commercial & industrial cold rooms, including:

The type of cold storage condensing unit is determined depend on the cold storage design and construction.

Whether water-cooled condensing unit or air cooled condensing unit, medium temp condensing unit or low temp condensing unit, they are all required to provide high reliability and high efficiency for cold storage industries.

Air cooler evaporator is indoor unit of the cold storage refrigeration equipment. In cold storage refrigeration cycle, the refrigerant in the air cooler evaporator absorbs heat from the cold storage room and evaporates to achieve the cooling effect. The selection of the evaporator and cold storage condensing unit plays an important role in cold storage refrigeration system design. In refrigeration systems, the size of the evaporator directly affects system performance, energy efficiency, and stability. Glen Refrigeration offers wide selection of the air cooler evaporator, including:

Although Glen Refrigeration is not the largest evaporator manufacturer in China, we are the company that best understands the importance of matching condensing units and cold room evaporators.

The expansion valve is used to regulate the refrigerant into the evaporator, ensuring accurate superheat control and efficient heat exchange. In cold storage refrigeration systems, the selection and matching of the condensing unit, evaporator unit and expansion valve is very important. Its selection directly affects the system’s refrigeration efficiency, operational stability, and equipment lifespan. Improper selection can lead to insufficient cooling, increased energy consumption, or even compressor damage.

Both excessively high or low refrigerant flow rates will affect the system’s efficiency during continuous operation. So proper expansion valve operation ensures stable superheat control, efficient heat exchange, and consistent temperature performance inside the cold room.

At same time, a good quality thermostatic expansion valve also plays a important role in cold storage refrigeration systems. Glen Refrigeration always insists to use Danfoss expansion valve, including the Danfoss r404a expansion valve and R449A expansion valve.

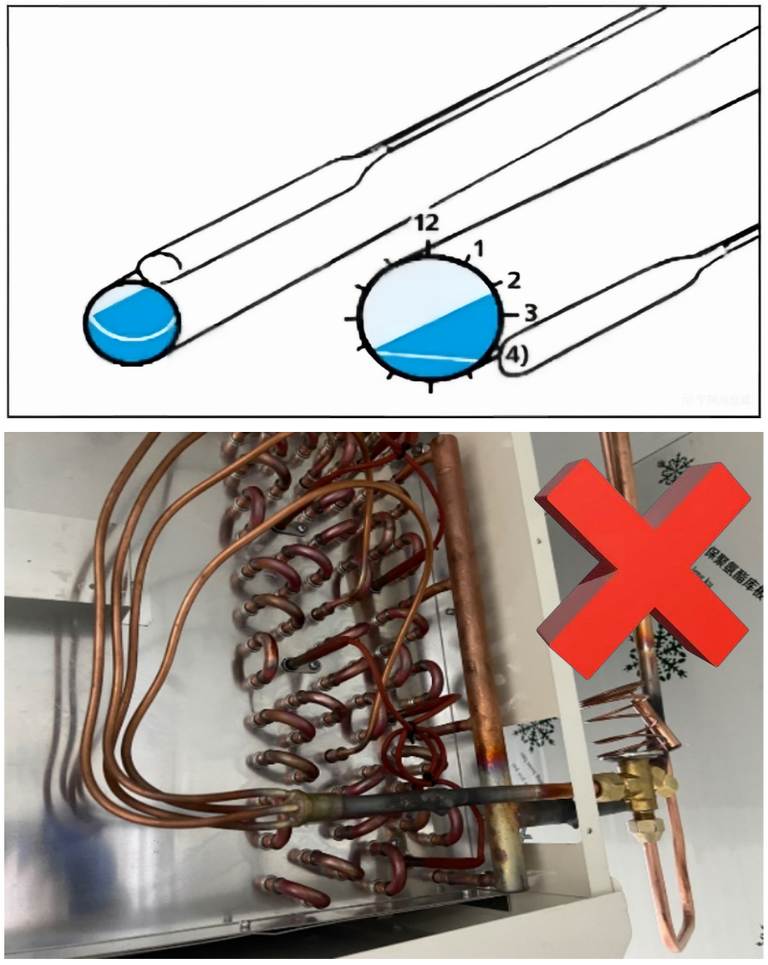

The last but most important, the correct installation of the refrigeration expansion valve temperature sensing bulb is a key factor in ensuring the efficient and stable operation of the refrigeration system.

The cold room controllers are used to manage cold storage room temperature regulation, defrost cycles, alarms and safety functions. It serves as the brain of the cold storage refrigeration. In cold storage applications, reliable controllers help optimize energy usage, maintain precise temperature settings, and respond quickly to abnormal operating conditions.

The selection of the cold room controllers should be according to the temperature requirements, condensing unit and evaporator and electric heater’s power and so on. For large cold storage facilities or cold storage requiring high temperature control accuracy (such as pharmaceutical cold storage), a control box with more complex control logic and higher precision should be selected.

The cold storage refrigeration system provides a stable, efficient, and reliable refrigeration performance; while the cold room panels and cold room doors are used to maintain the low temperature environment inside the cold storage room. The cold room panels and doors affect the refrigeration efficiency of cold storage, energy consumption, and the service life of cold storage. So the quality of cold room panels and cold room doors are as same important as the cold storage refrigeration units. Now most of the cold room panels and cold room doors used in the cold storage are polyurethane panel. They use lightweight polyurethane as the inner material. The surface material is made of color steel, stainless steel or embossed aluminum. According to different temperature and different requirements, the cold room panels can be divided according to the thickness, like 50mm, 75mm, 100mm, 120mm, 150mm, 200mm. It also can be divided according to surface materials, color steel, stainless steel, and embossed aluminum and the thickness of the surface materials.

Cold Room Panel According to Different Thickness

Cold Room Panel According to Different Surface Material

There are different kinds of cold room doors, including fully buried swing door, semi buried swing door, manual sliding door, electric sliding door, and so on. The most commonly used cold storage doors are semi buried swing door and sliding door. The swing door includes single open door and double open door. The thickness and the surface material of the cold room door can be customized according to customer’s need.

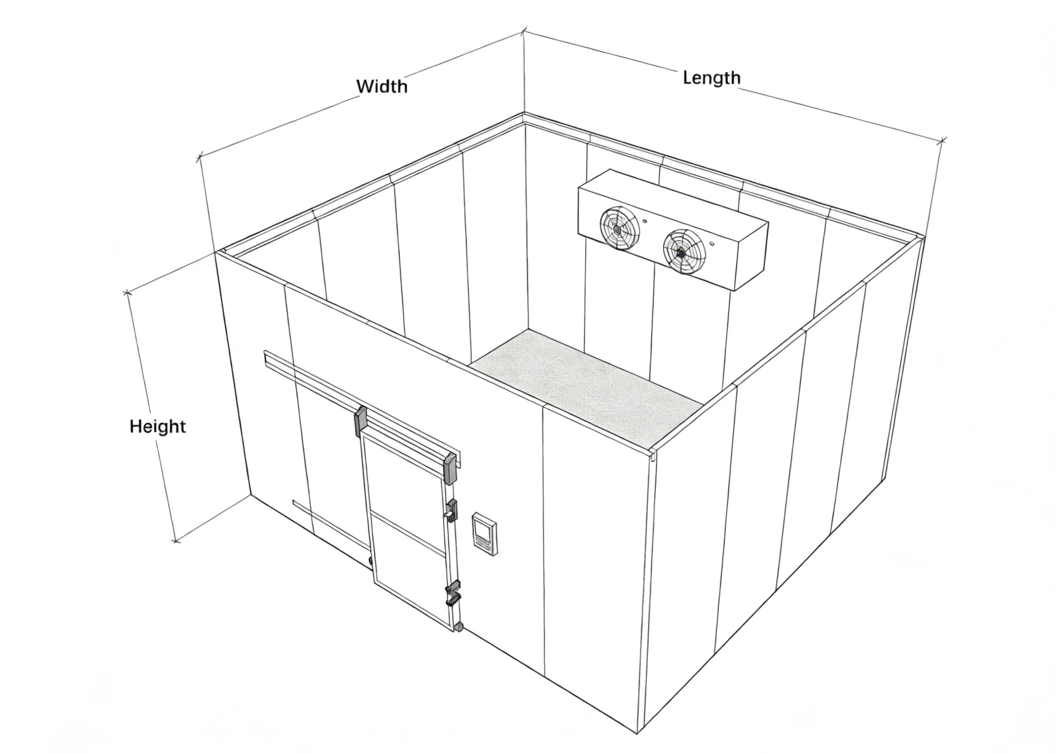

According to the cold storage dimension, it can be divided into small cold storage and large cold storage. The small cold rooms are essential for preserving food and perishable products, like Seafood Cold Storage, Flower Cold Storage, Meat Cold Storage, Vegetable Cold Storage, Milk Cold Storage, Fruit Cold Storage, Ice cream cold storage and so on. They are widely used in restaurants, hospitals, hotels, bakeries, butcheries and flower shops.

Seafood cold storage condensing unit, cold storage refrigeration system

Walk in freezer condensing unit and evaporator for meat cold storage

Walk in cooler condensing unit and evaporator for vegetable cold storage

Cold storage condensing unit and evaporator for milk and dairy

High efficiency Emerson ZB compressor condensing unit & evaporator

Low temperature condensing unit and evaporator for Ice cream cold storage

Emerson ZB compressor outdoor condensing unit for flower cold storage

Egg cold storage refrigeration system outdoor condensing unit and evaporator

Condensing unit and evaporator for banana Ripening chamber & cold storage

Reliability is the most important point for cold room condensing unit. Glen Refrigeration offers the cold room condensing units designed with high reliability. They perform well under different climates and project conditions.

The cold room refrigeration systems should be selected according to the cold room dimensions, storage volume, cold room panel thickness, door opening frequency and the type of products being stored. All of these factors determines the selection of condensing units.

The size and volume of a cold storage room are one of the most critical factors determining the size of a condensing unit. As the “heart” of a cold storage facility, the refrigeration unit’s function is to maintain the cold storage target temperature. The volume of the cold storage directly determines the size of the space that needs to be cooled, and which in turn determines the required cooling capacity. The larger the volume, the more heat needs to be removed, thus requiring a unit with a stronger cooling capacity.

If you are not sure how to size your refrigeration equipment?

Different applications, required storage temperature is different. The selection of the cold storage refrigeration systems should be according to its specific temperature ranges.

Different condensing unit has different evaporating temperature range. The evaporating temperature range determines its work temperature. For example, ZB compressor Copeland condensing unit with evaporating temperature range from -25°C to +5°C, suitable for medium temperature refrigeration and high temperature refrigeration.

For detailed system configurations based on temperature and usage, see our Cold Room Refrigeration System Solutions.

The ambient conditions such as outdoor temperature, humidity, and installation place, noise requirements are closely related to the selection of the condensing unit and cold room designs.

For high ambient environments, we will choose the high cooling capacity condensing unit and also enlarge enlarge the condenser coil to enhance the heat-dissipation to suit the high ambient temperature condition.

For the installation place and noise requirements, if the condensing units are installed outside of the hotel or residential area, a low noise and quite operation condensing unit is preferred.

If you use the condensing unit in a special ambient condition, not sure how to select your refrigeration equipment?

The high efficient condensing units play an important role in reducing electricity consumption and lower operating cost over time. Choosing inverter condensing unit and optimized refrigeration circuits can significantly improve system performance.

Inverter condensing unit is a condensing unit featuring inverter technology that help customers save energy use and costs. The inverter technology improves energy efficiency by efficiently controlling the commercial refrigeration compressor motor speed.

In inverter condensing unit, the cold storage room temperature is adjusted by changing the compressor speed without turning the compressor ON and OFF frequently. Compared to fixed speed condensing unit, variable speed condensing unit has less power loss and can save in energy.

For cold storage refrigeration, reliability is absolutely the most important thing. We ensures its high reliability from three aspects: material reliability, design reliability and production reliability. We use Sanyo compressor, Panasonic compressor and Copeland compressor, Sanhua four-way valve, Sanhua electronic expansion valve, Danfoss, Sanhua and Saginomiya pressure switch to ensure the material reliability. The design of the electric board helps our customer minimize troubleshooting time.

For assistance with selecting the most suitable cold storage refrigeration system for your application, contact us or explore our Cold Room Refrigeration System Guides and Product Pages.

In cold storage refrigeration systems, the condensing unit is the most important part and most complex part. So it plays a important role in determining the whole system performance, efficiency, and reliability. We choose the types of condensing units and cooling capacity of condensing units firstly according to the cold room designs.

The condensing unit is the heart of any cold storage refrigeration system. Its main function is to cool and condense the high-temperature, high-pressure refrigerant vapor discharged from the compressor into a liquid, while releasing heat to the external environment. The performance of condensing unit directly affects the cold storage refrigeration system’s performance.

The condensing unit significantly affects the efficiency of the cold storage refrigeration system, especially for most of the cold storage facilities running 24/7. Choosing an efficient condensing unit, such as the inverter condensing unit, it improves energy efficiency by efficiently controlling the compressor motor speed according to different refrigeration load, reducing electricity consumption, lower operating costs, and improve overall system sustainability.

For commercial refrigeration, reliability is often considered the top priority. The cold storage facilities run 24/7 to keep the required temperature for food or pharmaceutical or vaccine, so a high reliable condensing unit is what we need to consider first. The quality and design of the condensing unit must ensure the high reliability under continuous operation and it directly impact cold storage refrigeration system reliability.

The cold storage condensing unit is generally installed outside of the cold storage room or warehouse. Whether operating in high ambient temperatures or low ambient temperatures, the condensing unit must be capable of providing stable performance. Glen Refrigeration has rich experience and solutions. For example, to enlarge the condenser coil to enhance the heat-dissipation is one of the solutions to suit the high ambient temperature condition.

Outdoor Unit of Cold Storage Refrigeration

The condensing unit is one of the most important parts of the cold storage refrigeration system. It is including refrigeration compressor, condenser, fan motor, receiver, sight-glass, solenoid valve, high and low pressure switch, high and low pressure gauge, accumulator and so on. Some condensing units also have oil separator. Among these parts, refrigeration compressor is the heart of the cold storage cooling system. A good quality refrigeration compressor is the key of the cold storage condensing unit. Glen Refrigeration chooses Sanyo, Panasonic and Copeland compressor. They are all famous brands and of high quality.

Glen Refrigeration offers outdoor condensing unit featuring Sanyo refrigeration compressor for small cold storage refrigeration, including 1 HP condensing unit, 1.5 hp condensing unit, 2 hp condensing unit, 2.5 hp condensing unit, 3 hp condensing unit. The power supply is available in 220V~240V/50HZ, 220V/60HZ, 380V/50HZ. Compressor is one of the most important part in condensing unit, while Sanyo compressor is famous for its high reliability.

Using Emerson high efficiency ZB scroll compressors, Glen refrigeration offers 2 HP condensing unit to 25 Hp condensing unit for high temperature and medium temperature cold storage refrigeration. The voltage is available in 220V~240V/50HZ, 220V/60HZ, 3 phase, 380V/50HZ, 3 phase.

Glen Refrigeration offers ZF compressor Emerson condensing unit for medium temperature and low temperature cold storage refrigeration. The cooling capacity available in 3 HP, 4 HP, 5 HP, 6 HP, 7 HP, 8 HP, 10 HP, 12 HP, 15 HP, 18 HP. The ZF*KQE scroll compressor that operate with liquid injection through discharge temperature valve (DTC valve) to control the discharge temperature.

The ZFI Emerson scroll compressor is designed for exceptional low temperature performance with vapor injection technology. Glen refrigeration offers vapor injection ZFI compressor outdoor condensing unit from 4 HP to 25 HP for low temperature cold storage refrigeration.

Glen refrigeration offers ZSI compressor Emerson condensing unit, cooling capacity available in 3 HP, 4 HP, 5 HP, 6 HP, 7 HP. The ZSI scroll compressor features liquid injection cooling technology, controlled by CoreSense control board, it can regulate the liquid injection by sensing the discharge temperature. Evaporate temperature from -30°C to 0°C, designed for medium temperature and low temperature cold storage refrigeration.

Glen Refrigeration offers Panasonic medium temp condensing unit and low temp condensing unit for cold storage refrigeration. The low temp condensing unit with liquid injection cooling, solving the high discharge temperature under low evaporating temperature condition. Panasonic compressor that providing lower sound level, makes the outdoor condensing unit operating more quietly.

Glen refrigeration offers water cooled condensing unit for cold storage refrigeration. The water cooled condensing unit uses plate heat exchanger as condenser, which has the advantages of better heat transfer, easier maintenance and cleaning, and compactness.

We offer Copeland water cooled condensing unit including ZB series compressor Copeland water cooled condensing unit, ZF series compressor Copeland water cooled condensing unit, ZFI series compressor Copeland water cooled condensing unit and variable speed water cooled condensing unit.

Indoor Unit of Cold Storage Refrigeration

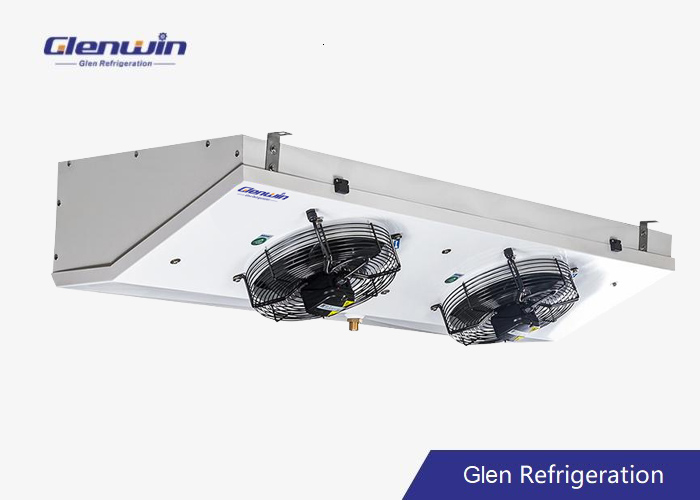

Air cooler evaporator is indoor unit of the cold storage refrigeration equipment. The selection of the evaporator and cold storage condensing unit plays an important role in cold storage refrigeration system design. In cold storage refrigeration cycle, the refrigerant in the air cooler evaporator absorbs heat from the cold storage room and evaporates to achieve the cooling effect. The evaporator will not only affect the performance of outdoor condensing unit, but also the quality of the cold storage refrigeration systems. Glen Refrigeration offers wide selection of the air cooler evaporator, including the slim type ceiling air cooler, dual discharge evaporator and box evaporator. Although we are not the largest evaporator manufacturer in China, we are the company that best understands the importance of matching condensing units and cold room evaporators.

Glen Refrigeration offers low profile slim type air cooler evaporator for cold storage systems refrigeration. It is ideal for small cold storage room like catering, retail, and gas stations. It delivers reliable cooling at temperatures above and below zero degrees. The air cooler operates quietly and offers a cost-effective cooling solution, perfect for businesses looking to maintain a comfortable environment while saving space and money.

The dual discharge evaporator is designed with ultra-thin structure, with air outlet on both sides. It is mainly used in processing rooms. It provides a more even distribution of the cooling air, which cools the room efficiently and evenly. The flat ceiling design allows for optimal utilization of space. Glen refrigeration offers good quality air evaporator. It makes us stand out of these evaporator manufacturers. Because the air cooler not only affect the cooling performance of the cold storage systems refrigeration, but also affect the reliability of cold storage condensing unit.

The box type evaporator is most common in cold storage refrigeration. It widely used in cold room and freezer room. According to the different cold storage temperature, the box evaporator can be divided into DD series and DJ series. DD series unit coolers with evaporator fin spacing 6.5mm~7mm designed for 2~8 ℃ cold storage room and -18°C freezer cold room. It delivers reliable cooling at temperatures above and below zero degrees. DJ series low temperature evaporator with evaporator fins spacing 9mm designed for -25 ℃ quick frozen room.

Brings the advantages of easy installation and service

The outdoor condensing units and unit coolers are split system refrigeration cycle, while there is another kind of cold storage refrigeration cycle, that is monoblock refrigeration unit. It integrates condensing unit and air cooling evaporator into one package refrigeration system, brings the advantages of easy installation and service to the end users. The refrigerant of the cold storage refrigeration units has been pre-charged. Customers no need to charge the refrigerant anymore. It becomes more and more popular in cold storage market. Glen Refrigeration offers three differents monoblock refrigeration units, including wall mounted refrigeration unit, ceiling mounted monoblock refrigeration unit and monoblock R290.

This is Wall mounted refrigeration unit, also called Monoblock Refrigeration Unit, it integrated the condensing unit and evaporate unit together, featuring Sanyo inverter refrigeration compressor, EBM and WEIGUANG motor. The inverter wall mounted refrigeration unit has already charged in the refrigerant, makes customer easy to install and easy to maintenance. The cooling capacity is available in 1 HP, 2 HP, 3 HP and 4 HP. The power supply is available in 220V~240V/50HZ and 220V/60HZ.

Ceiling mounted monoblock refrigeration unit, characterized by remarkable compactness, allows to optimize the useful space inside the cold room, guaranteeing excellent performance, reliability and efficiency. The Sanyo inverter compressor combines intelligent variable speed controller provide a high efficiency and energy saving solution. The Sanhua electronic expansion valve precisely controls the refrigerant flow rate, ensuring the refrigerant effectively evaporate in the evaporator. The series of ceiling mounted refrigeration unit includes 1 HP, 2 HP and 3 HP. The power supply is available in 220V~240V/50HZ and 220V/60HZ.

Pursuing the objectives of climate-friendly and efficiency, the monoblock refrigeration unit adopts R290 compressor. Synergy operation of the R290 inverter refrigeration compressor and the intelligent controller provides higher efficiency. The evaporator is a dual discharge evaporator, in low height, ensures the largest effective volume of the cold storage room. Dual discharge evaporator with air outlet on both sides, provides a more even distribution of the cooling air.

Glen Refrigeration is a cold room evaporator and cold room condensing unit manufacturer in China. We professionally manufacture the commercial refrigeration condensing unit and evaporator unit for more than 10 years. We stay close to our customers, better understanding our customers’ need, design and produce the customer-focused products. Over the years, our products and our designs have been proven to be high reliable, efficient, cost-effective and east to operate. Our Inverter Condensing Unit have enable us to exceed expectations in delivering quality and performance to our client’s needs. Glen Refrigeration offer wide range of condensing unit from fridge condensing unit, cooler condenser unit, horizontal condensing unit, air cooled condensing unit, water cooled condensing unit, indoor condensing unit, outdoor condensing unit, fixed speed condensing unit, variable speed condensing unit, R290 condensing unit, R404A condensing unit, low temp condensing unit, medium temp condensing unit, walk in freezer condensing unit, walk in cooler condensing unit and evaporator, remote condensing unit for commercial refrigeration and cold storage refrigeration.

As a commercial refrigeration condensing unit specialist in China, we primarily identify your needs to provide custom-focused solutions for your requirements. We apply up-to-date technology to our products. Most importantly, commercial refrigeration is quite different from air conditioner application. Commercial refrigeration condensing unit has much longer continuous running hours than air conditioner. At same time, it will face many problems, like high compression ratio, compressor discharge temperature over high, high and low pressure out of range, and many other problems. According to these problems, we ensure that our products has high reliability.

As our client, you can rest assured knowing you’re in the hands of a company whose reputation delivers. We take pride in our delivered products and value long term relationships with our customers. From small condensing unit to large outdoor condensing unit, we can provide specialized refrigeration solutions that suit your business’s needs.

We will contact you within 8 hours. Please pay attention to the email with the suffix “@greehvacr.com”.

The experts at Glen Refrigeration will be happy to help you choose the cold room that perfectly suits your business needs – if you’d like further advice on choosing a cold room, you can get in touch with us via whatsapp 0086 15057108995 via emailing info@greehvacr.com, or by submitting a response on our contact form below.

We will contact you within 8 hours. Please pay attention to the email with the suffix “@greehvacr.com”.